Add all missing English translations of MD documents

... using Google translate + manual MD syntax fixing

This commit is contained in:

260

corne-cherry/doc/v2/buildguide_en.md

Normal file

260

corne-cherry/doc/v2/buildguide_en.md

Normal file

@@ -0,0 +1,260 @@

|

||||

# Build Guide

|

||||

|

||||

This is the build guide for Corne Cherry v2.

|

||||

[Corne Cherry v3 build guide](

|

||||

https://github.com/foostan/crkbd/blob/master/corne-cherry/doc/v3/buildguide_en.md).

|

||||

|

||||

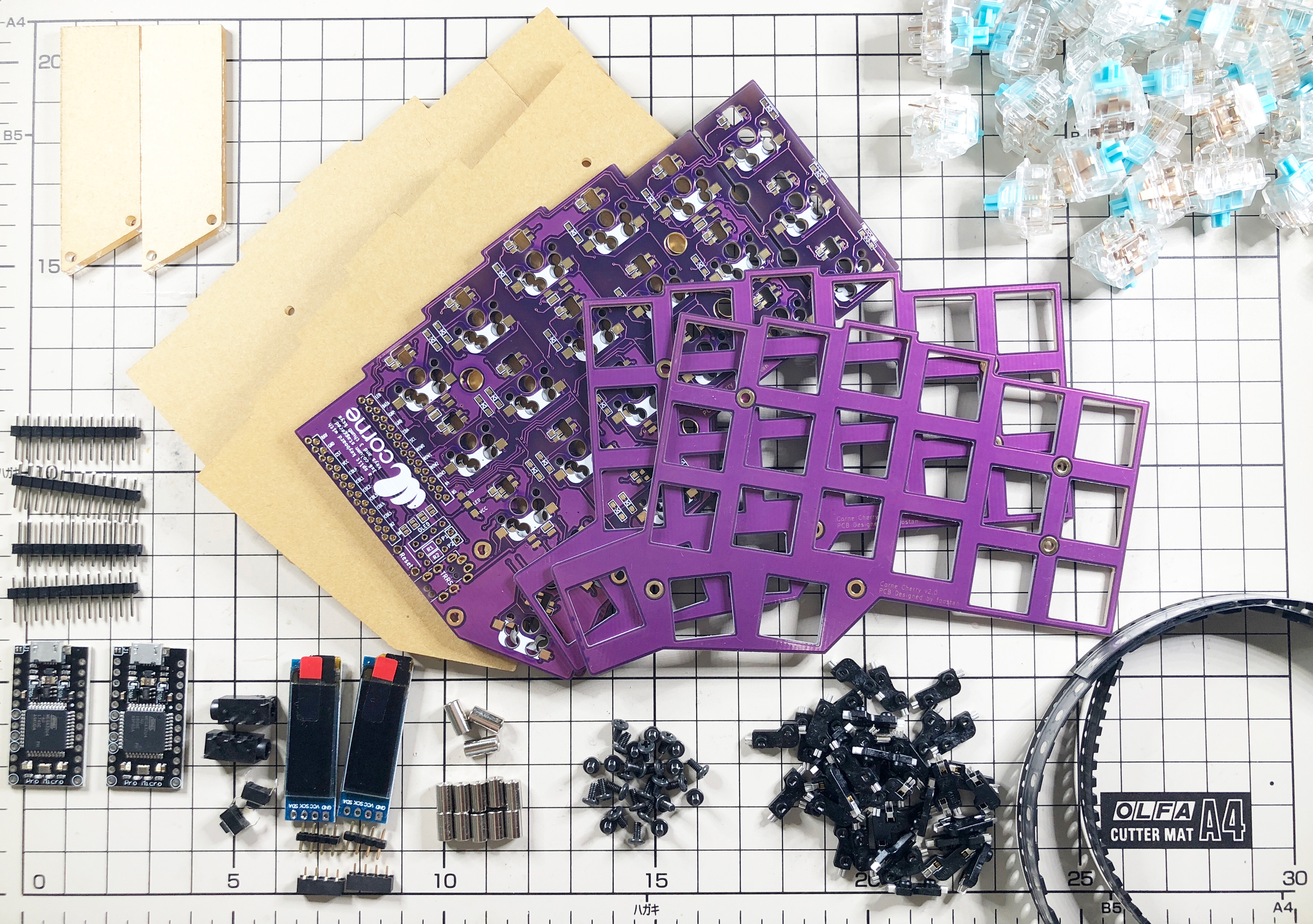

## Parts

|

||||

|

||||

### Required

|

||||

|

||||

| Name | Number | Remarks |

|

||||

|:-|:-|:-|

|

||||

| PCB | 2 sheets | |

|

||||

| Top plate | 2 sheets | |

|

||||

| Bottom plate | 2 sheets | PCB type and acrylic type can be selected |

|

||||

| ProMicro protective plate | 2 sheets | |

|

||||

| ProMicro | 2 sheets | |

|

||||

| TRRS jack | 2 | |

|

||||

| Tact switch | 2 | |

|

||||

| Diodes | 42 | Only chip parts |

|

||||

| Kailh PCB Sockets | 42 | |

|

||||

| Key switches | 42 | Only compatible with CherryMX |

|

||||

| Keycaps | 42 pcs | 1u 40 pcs, 1.5u 2 pcs |

|

||||

| OLED module | 2 sheets | |

|

||||

| 4 pin headers | 2 | |

|

||||

| 4 pin sockets | 2 | |

|

||||

| Spacer M2 7.5mm | 10 pieces | |

|

||||

| Spacer M2 9mm | 4 pieces | |

|

||||

| Screw M2 4mm | 28 screws | |

|

||||

| Cushion rubber | 8 pieces | |

|

||||

| TRS (3-pole) cable | 1 | TRRS (4-pole) cable is also acceptable |

|

||||

| Micro USB cable | 1 | |

|

||||

|

||||

### Options

|

||||

|

||||

| Name | Number | Remarks |

|

||||

|:-|:-|:-|

|

||||

| SK6812MINI | 54 pcs | Upward mounting 42 pcs, Downward mounting 12 pcs |

|

||||

|

||||

|

||||

|

||||

## Advance preparation

|

||||

|

||||

If you build the firmware yourself,

|

||||

it takes time to prepare the environment,

|

||||

so it is recommended to start first. \

|

||||

See <https://github.com/foostan/crkbd/blob/master/doc/firmware_en.md> for more information.

|

||||

|

||||

## Implementation

|

||||

|

||||

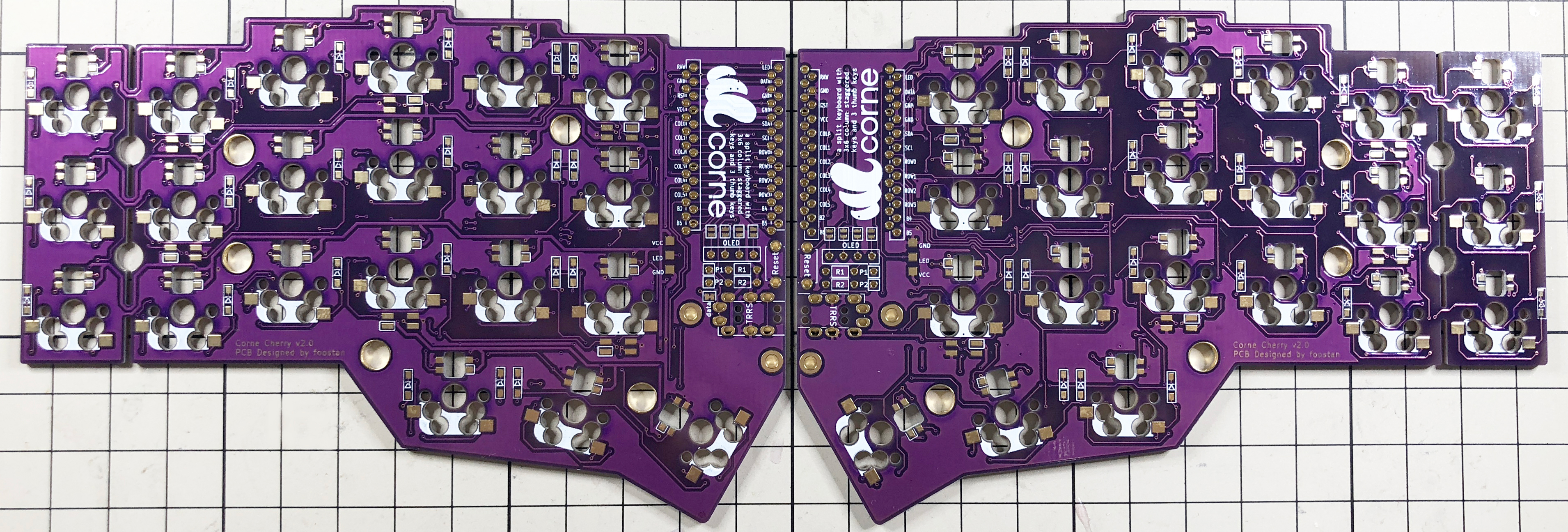

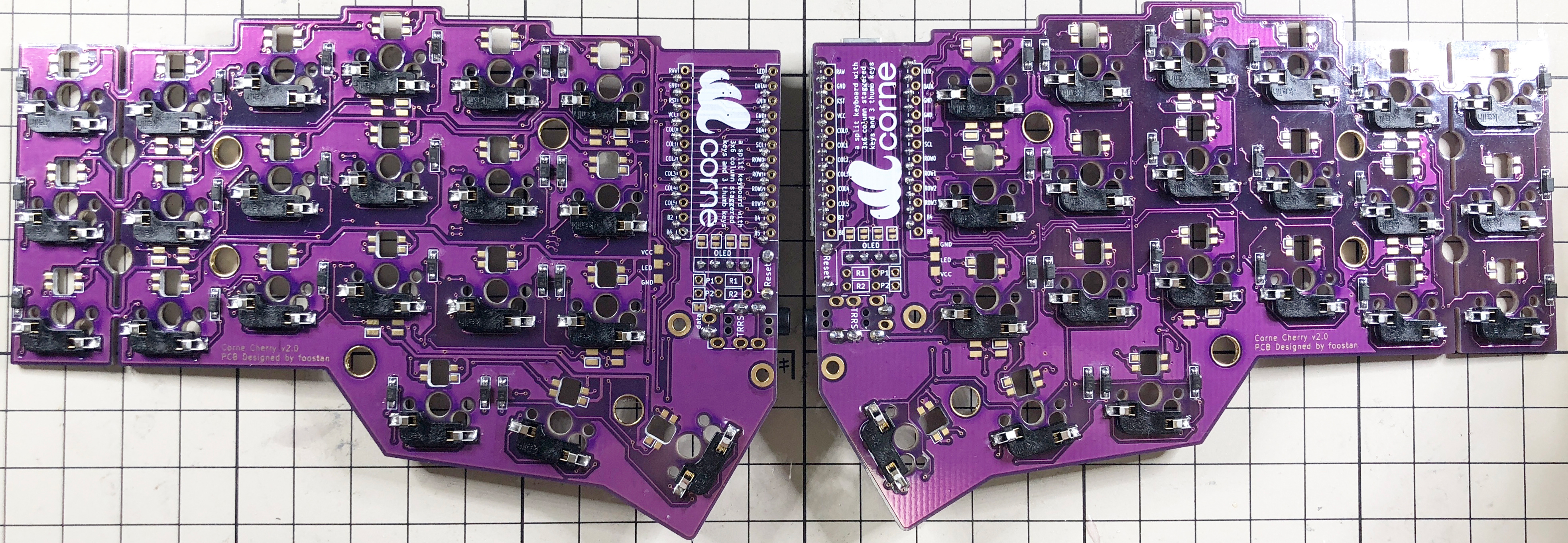

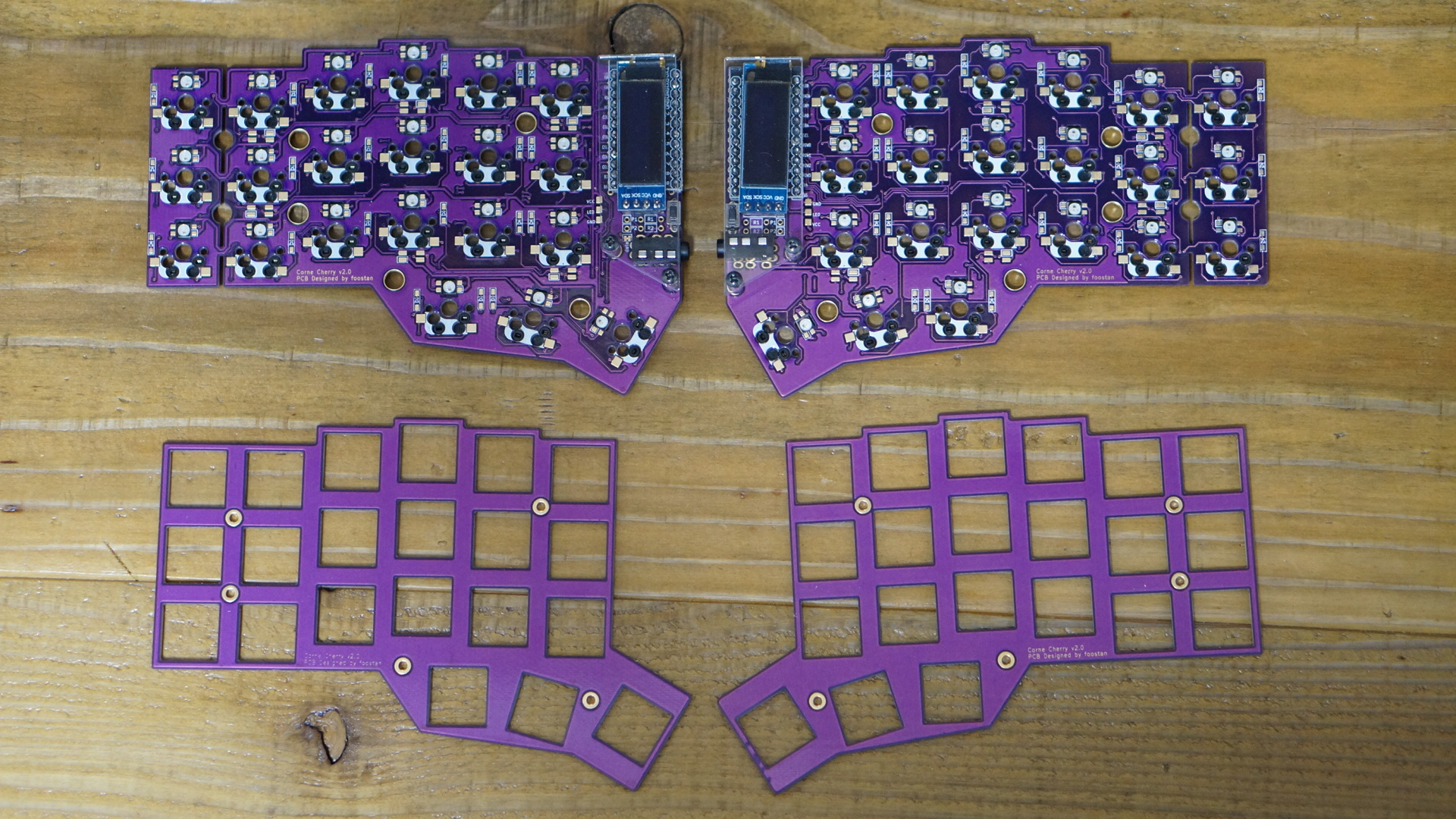

The PCB is reversible, so first decide which one to use,

|

||||

left or right.

|

||||

|

||||

|

||||

|

||||

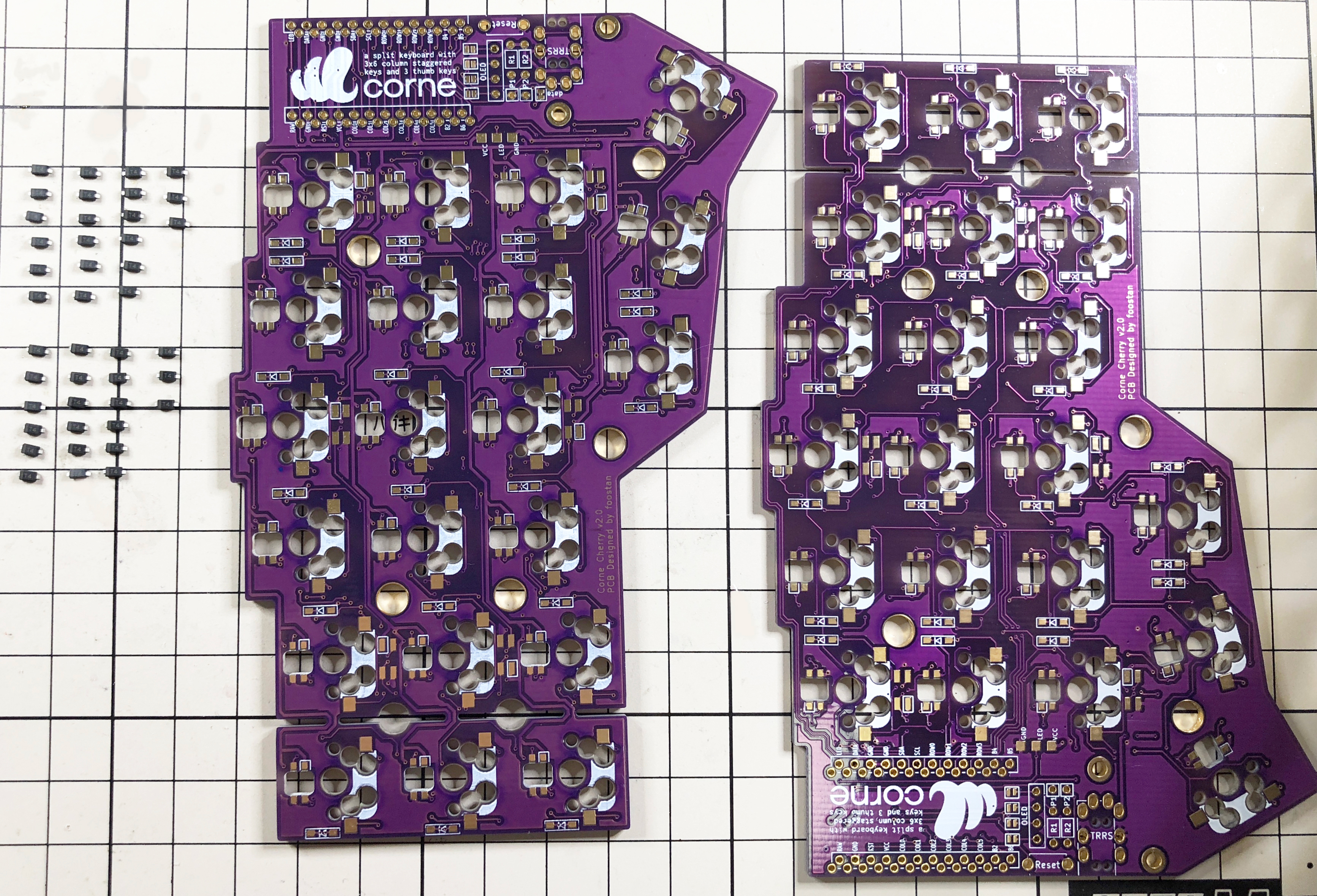

### Diode

|

||||

|

||||

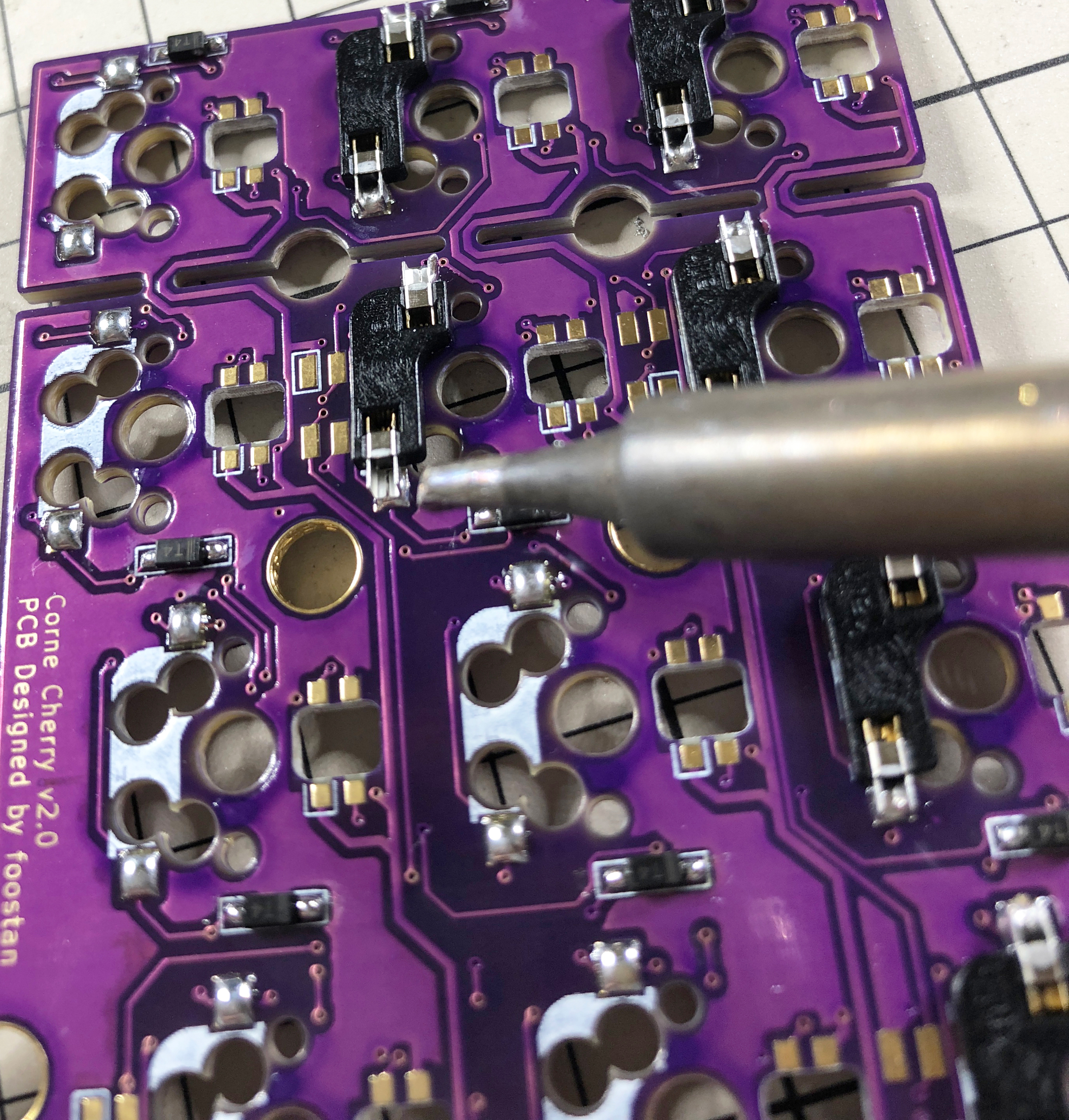

Solder the diode of the chip part.

|

||||

You can attach it to either side, but in this build guide,

|

||||

we will attach it to the back side.

|

||||

When using [Tilting / Tenting plate](

|

||||

https://github.com/foostan/crkbd/blob/master/corne-cherry/doc/buildguide_tilting_tenting_plate_en.md),

|

||||

be sure to attach it to the back side \_\_.

|

||||

|

||||

Since the chip parts are very small,

|

||||

it is easier to work with tweezers and counter-acting tweezers.

|

||||

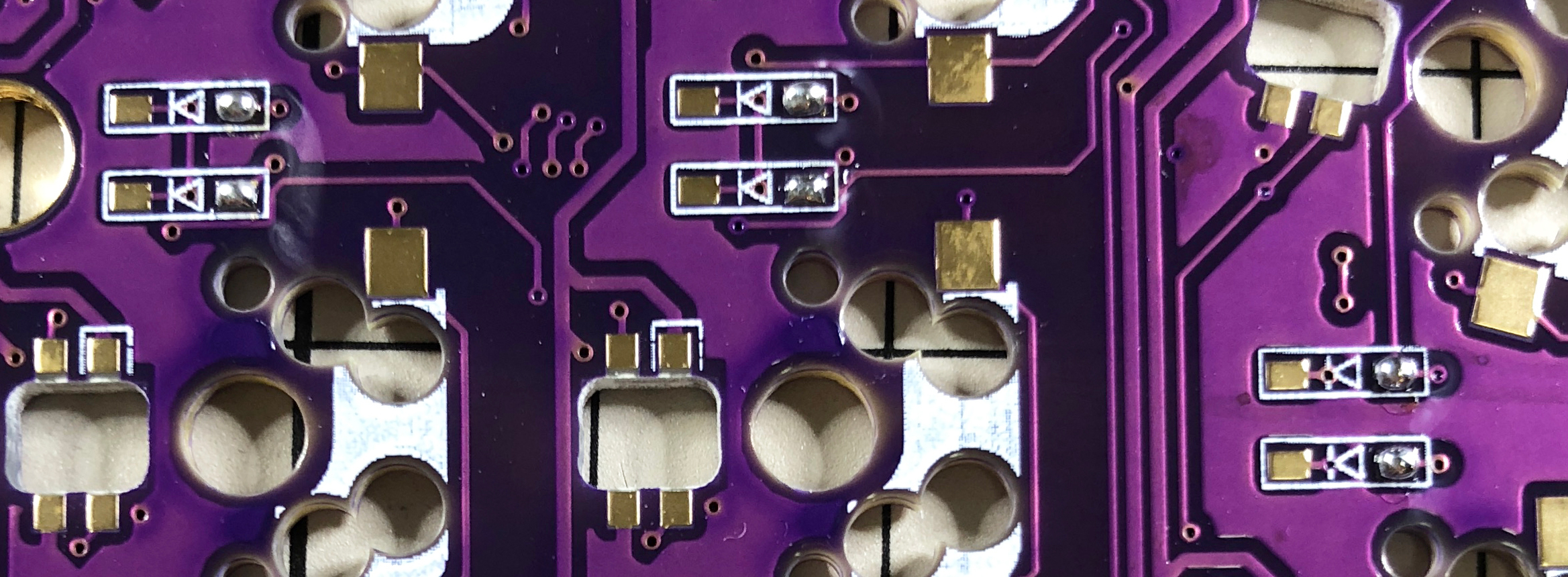

**The diode is installed in a fixed direction **,

|

||||

so if you arrange the diode in the same row and row as shown in the photo below,

|

||||

it will proceed smoothly.

|

||||

|

||||

|

||||

|

||||

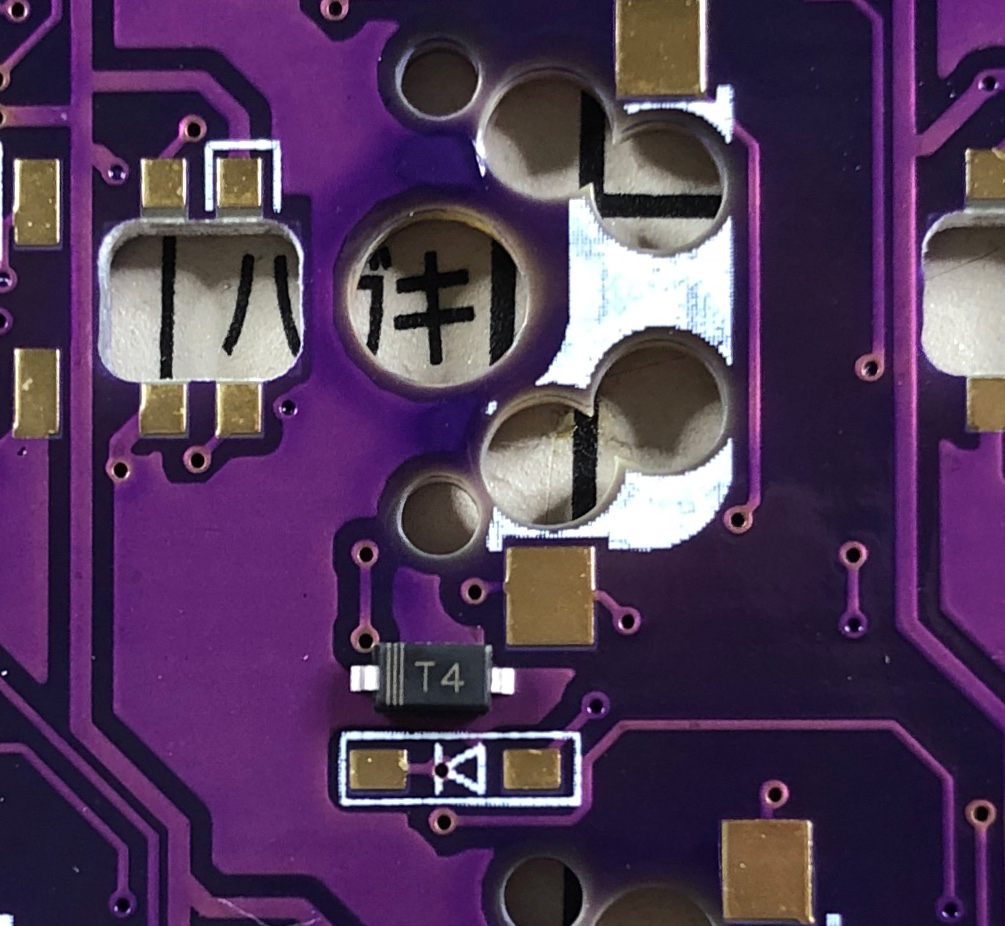

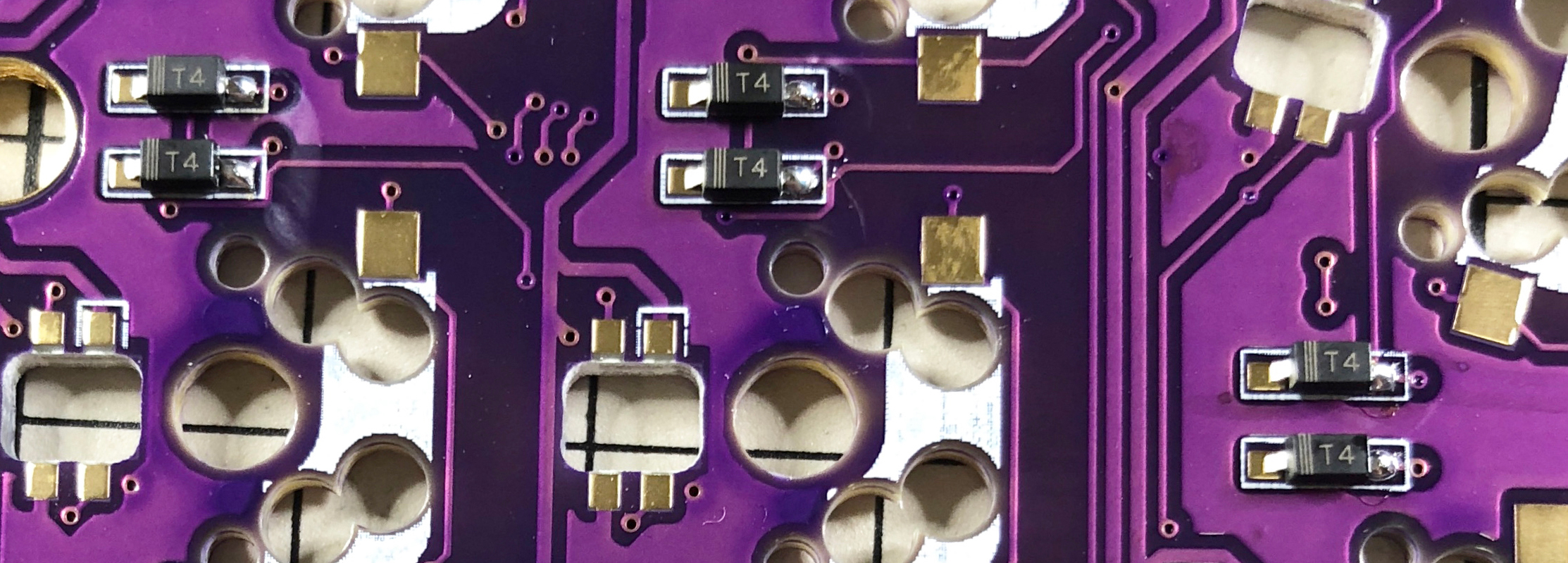

The orientation of the diode is as follows:

|

||||

Install so that the "|||" mark on the chip part faces the "|" of the diode mark "|◁".

|

||||

|

||||

|

||||

|

||||

The trick is to attach the chip parts, but first, as a spare solder,

|

||||

put the solder only on the right side of the pad.

|

||||

|

||||

|

||||

|

||||

Next, solder one leg of the diode so that the spare solder melts.

|

||||

At this time, it is recommended to use reverse-action tweezers,

|

||||

because you can hold the chip parts firmly without exerting force

|

||||

and you can concentrate on alignment and soldering.

|

||||

Also, if the soldering iron is too hot or the solder is touched too much,

|

||||

the flux contained in the solder may evaporate and form a clean pile of solder,

|

||||

but it can be repaired later,

|

||||

so at this point you should only be aware of attaching parts.

|

||||

It's okay.

|

||||

|

||||

|

||||

|

||||

It is okay if the diode does not float when viewed from the side

|

||||

when one foot is attached.

|

||||

If it floats, press the diode with tweezers

|

||||

or your fingers and reheat the soldered part with a soldering iron to clean it.

|

||||

|

||||

|

||||

|

||||

Then solder the other one.

|

||||

Be careful not to apply too much as a small amount of solder is sufficient.

|

||||

If you apply too much, you can remove it with a blotting wire

|

||||

or by scooping it with a soldering iron.

|

||||

|

||||

If the amount of solder on the preliminary solder side is small,

|

||||

additional soldering is performed, and if it is a mountain,

|

||||

apply flux from above and heat it to clean it.

|

||||

|

||||

|

||||

|

||||

### TRRS jack, reset switch

|

||||

|

||||

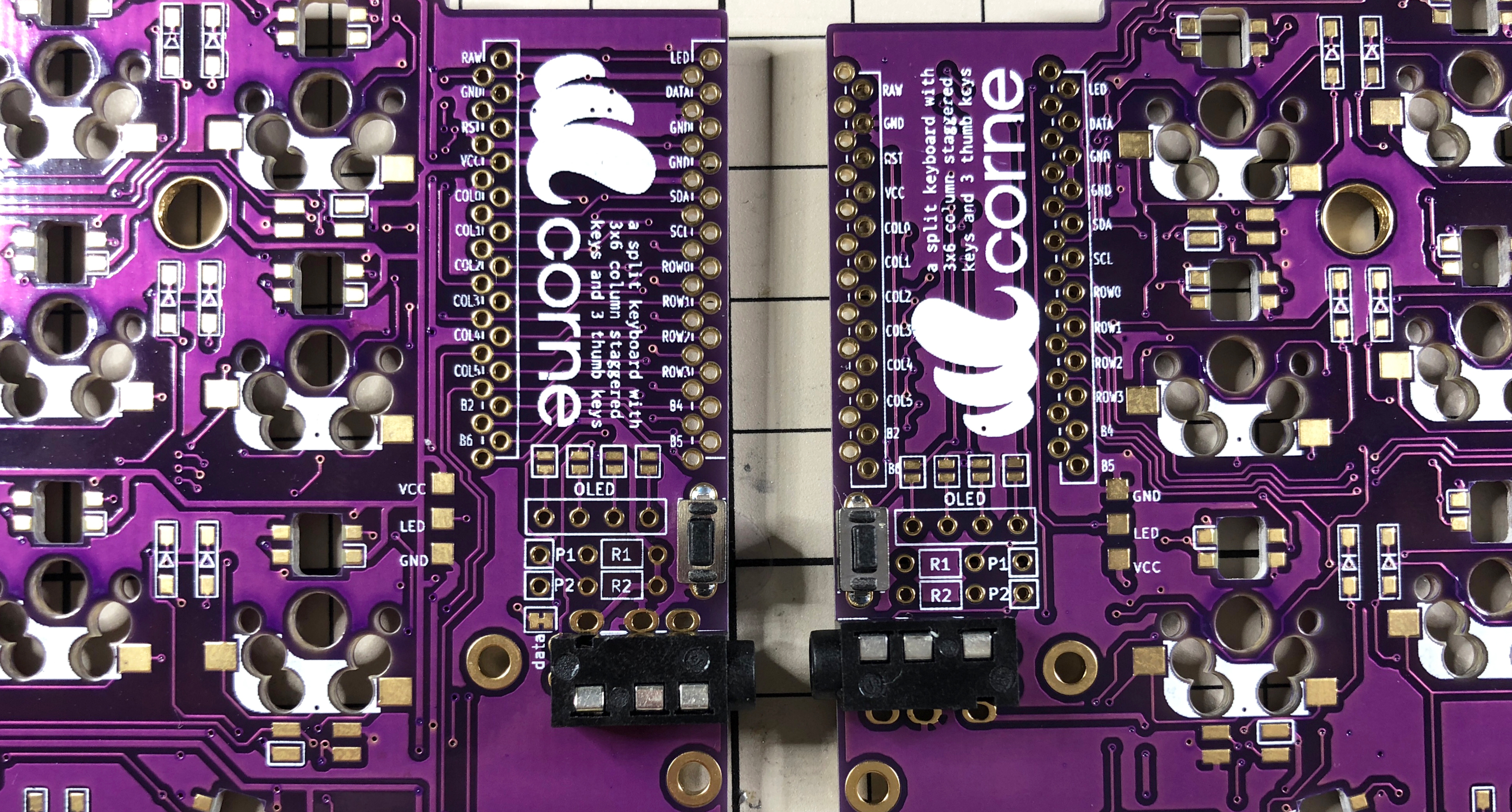

Solder the TRRS jack and reset switch to the surface of the PCB

|

||||

as shown in the picture below.

|

||||

In this build guide, the diode is attached to the back side,

|

||||

so it is the opposite side.

|

||||

|

||||

|

||||

|

||||

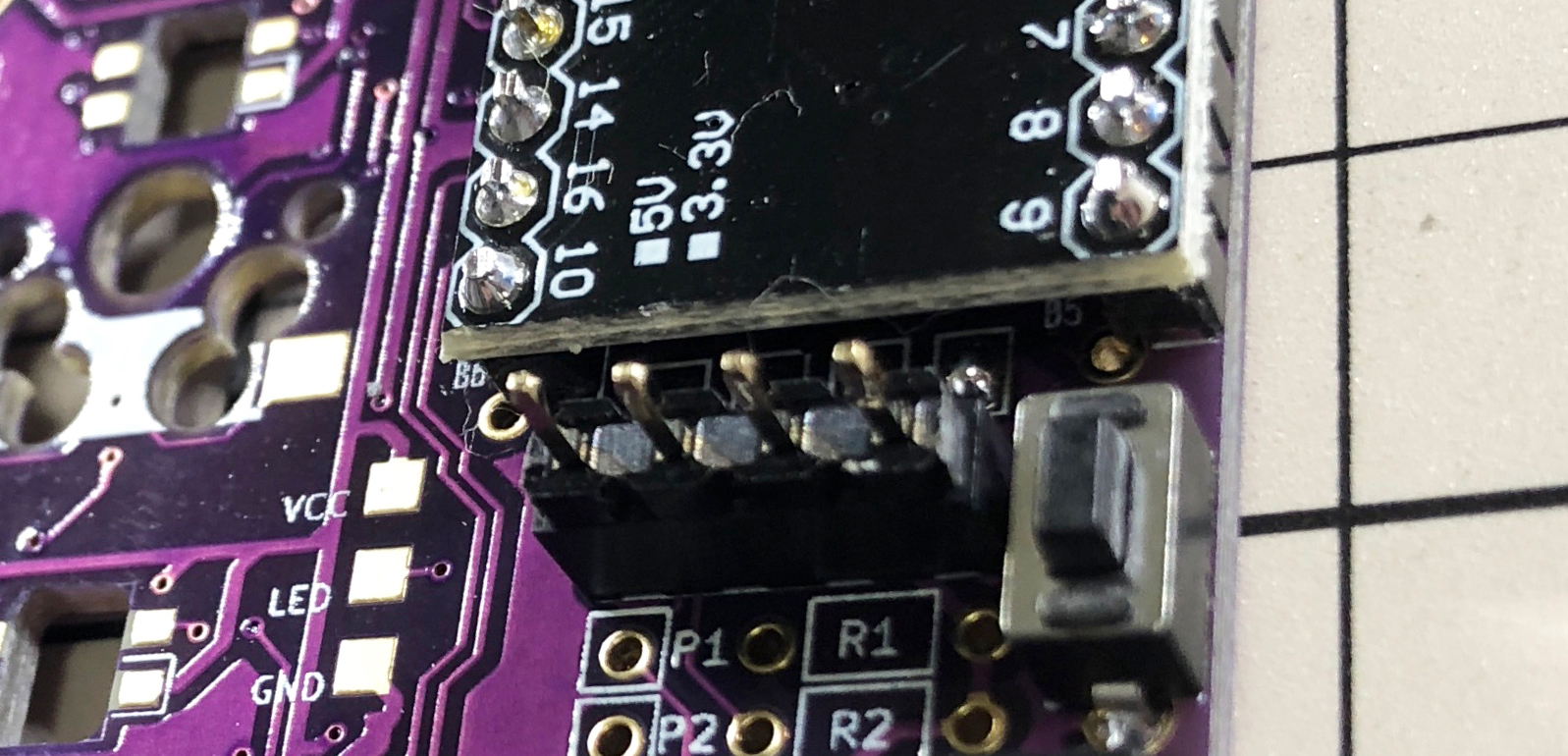

### Jumpers and pin sockets for OLED modules

|

||||

|

||||

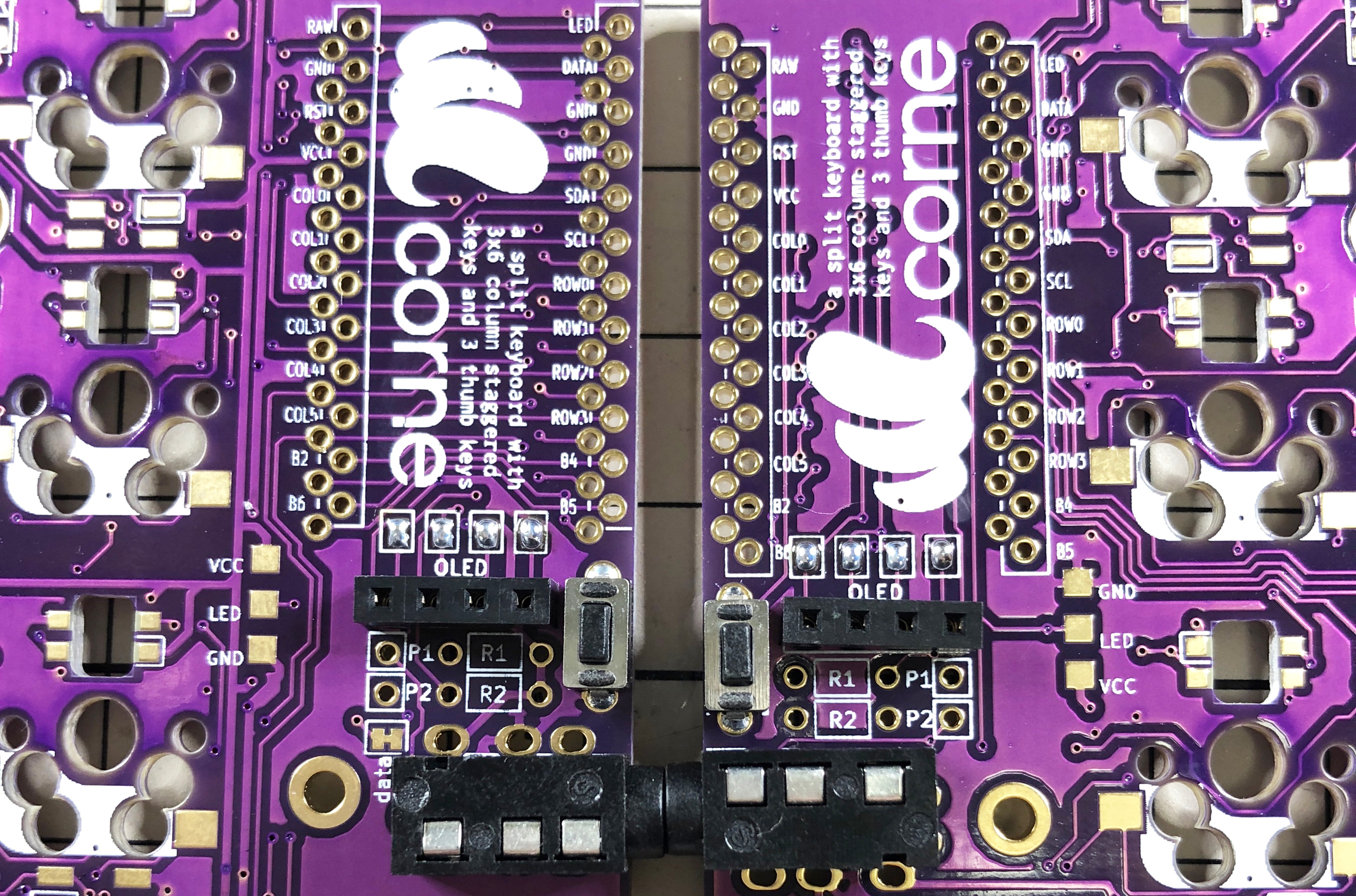

When using the OLED module, jumper as shown below.

|

||||

Please note that **only the surface should be jumpered**.

|

||||

|

||||

Solder the pin socket to the same surface.

|

||||

|

||||

|

||||

|

||||

If the jumper doesn't work, the amount of solder is probably too low

|

||||

or the flux in the solder has vaporized.

|

||||

In that case, you can fix a jumper by using a large amount of solder

|

||||

or applying a separate flux.

|

||||

|

||||

### ProMicro

|

||||

|

||||

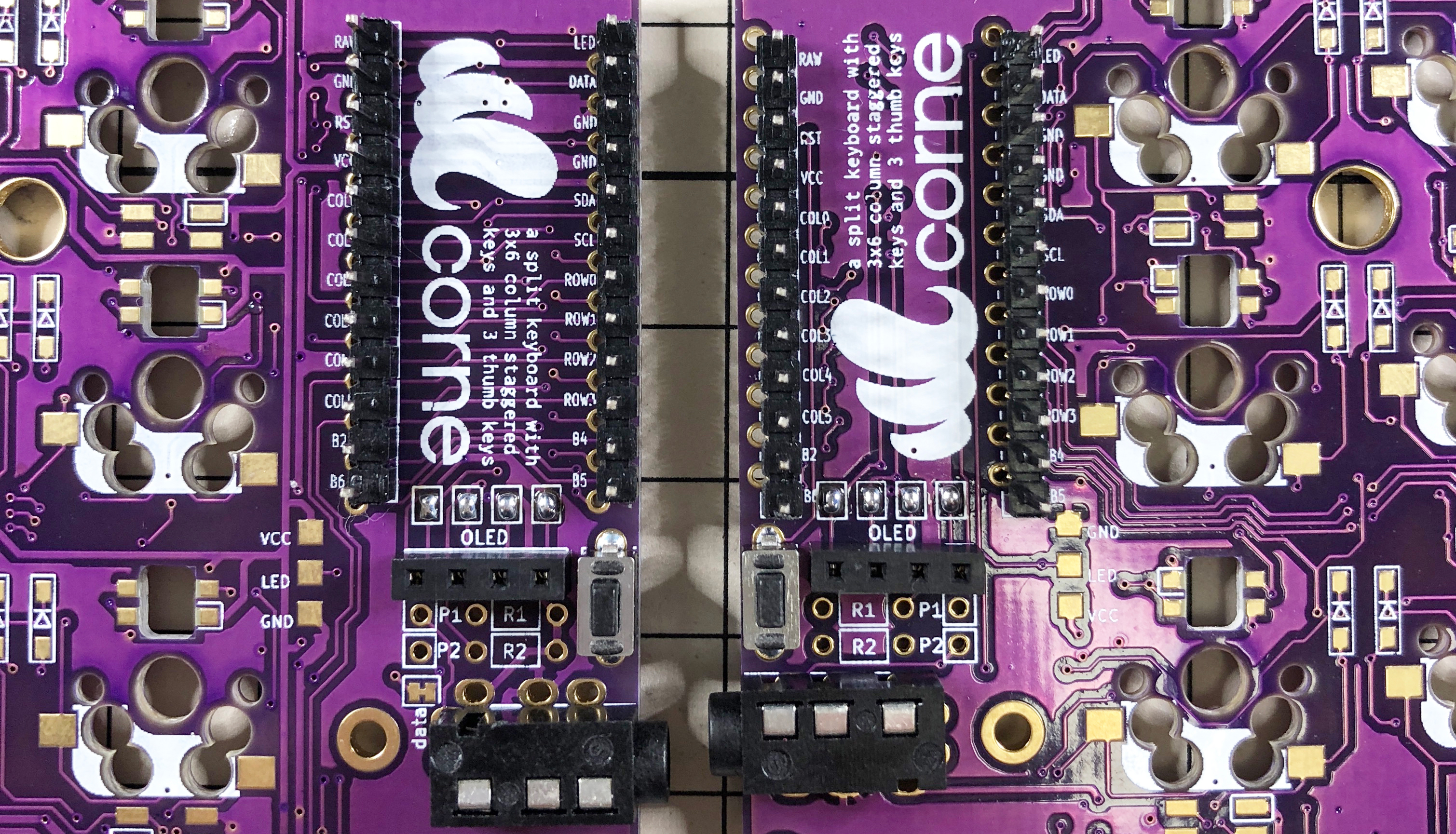

Solder the pin header so that it fits into the white frame,

|

||||

and then solder it with the back side of the Pro Micro facing up.

|

||||

|

||||

|

||||

|

||||

|

||||

If you want to use the spring pin header,

|

||||

please refer to [Helix Build Guide](

|

||||

https://github.com/MakotoKurauchi/helix/blob/master/Doc/buildguide_en.md#pro-micro).

|

||||

|

||||

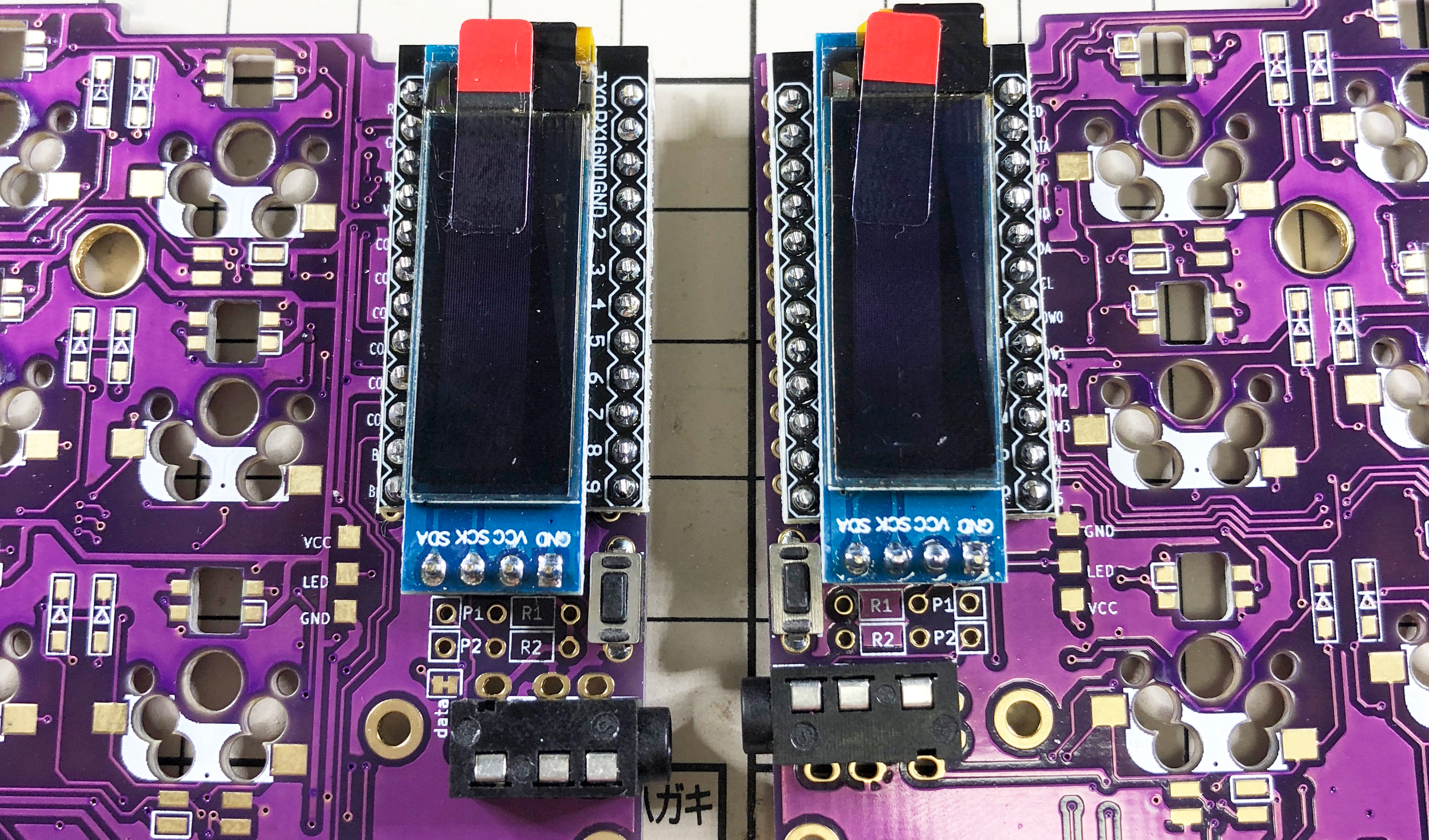

### OLED module

|

||||

|

||||

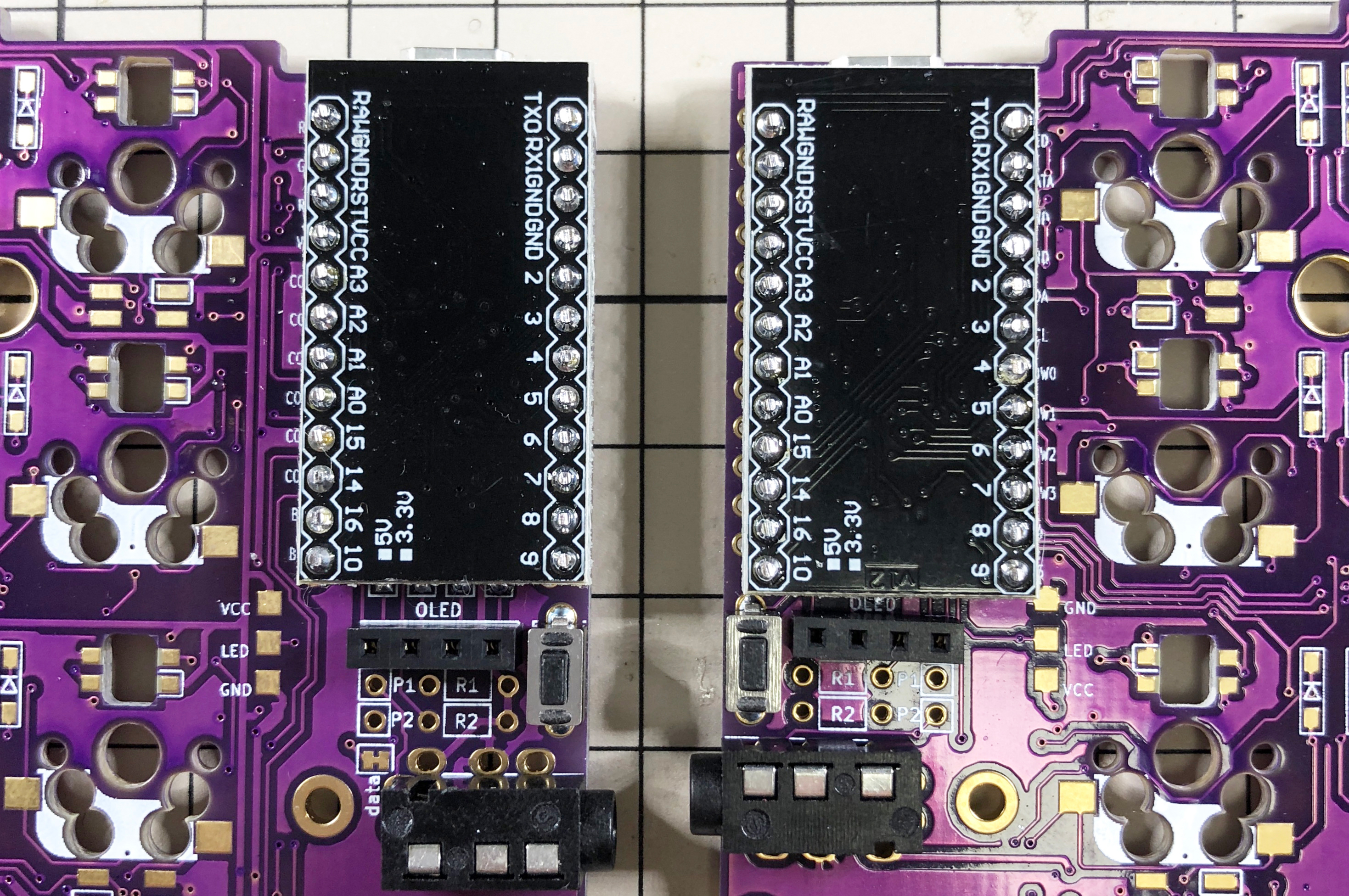

Insert the pin header into the pin socket for OLED first,

|

||||

and then solder the pin header and OLED module.

|

||||

At this time, the OLED module is easy to float,

|

||||

so be careful not to float it while pressing it with your finger.

|

||||

|

||||

|

||||

|

||||

|

||||

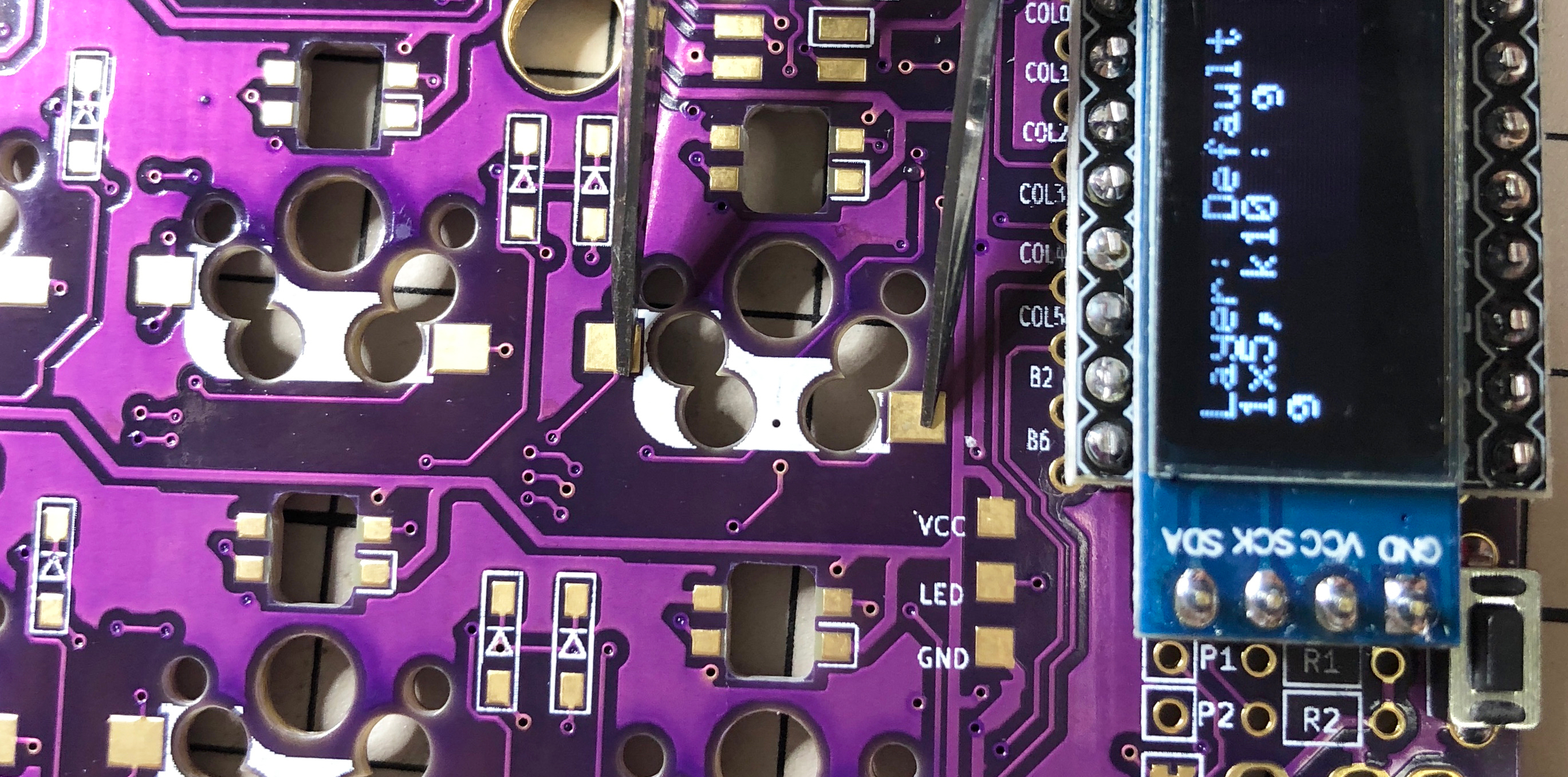

### Operation check

|

||||

|

||||

It is recommended to check the operation when ProMicro and OLED module are attached

|

||||

(it will be difficult to isolate the problem if you do it at the very end).

|

||||

|

||||

To check the operation, first insert the firmware for crkbd into ProMicro

|

||||

by referring to the "Firmware" chapter below (be sure to insert it on both sides).

|

||||

|

||||

To check the operation, connect the left hand side to the PC with MicroUSB

|

||||

and connect the left hand side and the right hand side with the TRS cable.

|

||||

Since there may be defects such as jacks,

|

||||

be sure to connect the left and right instead of one by one before checking the operation.

|

||||

If it is done correctly so far,

|

||||

if you short the pad to attach the PCB socket with tweezers etc.,

|

||||

the key pressed on the OLED module will be displayed.

|

||||

|

||||

|

||||

|

||||

### Kailh PCB Socket

|

||||

|

||||

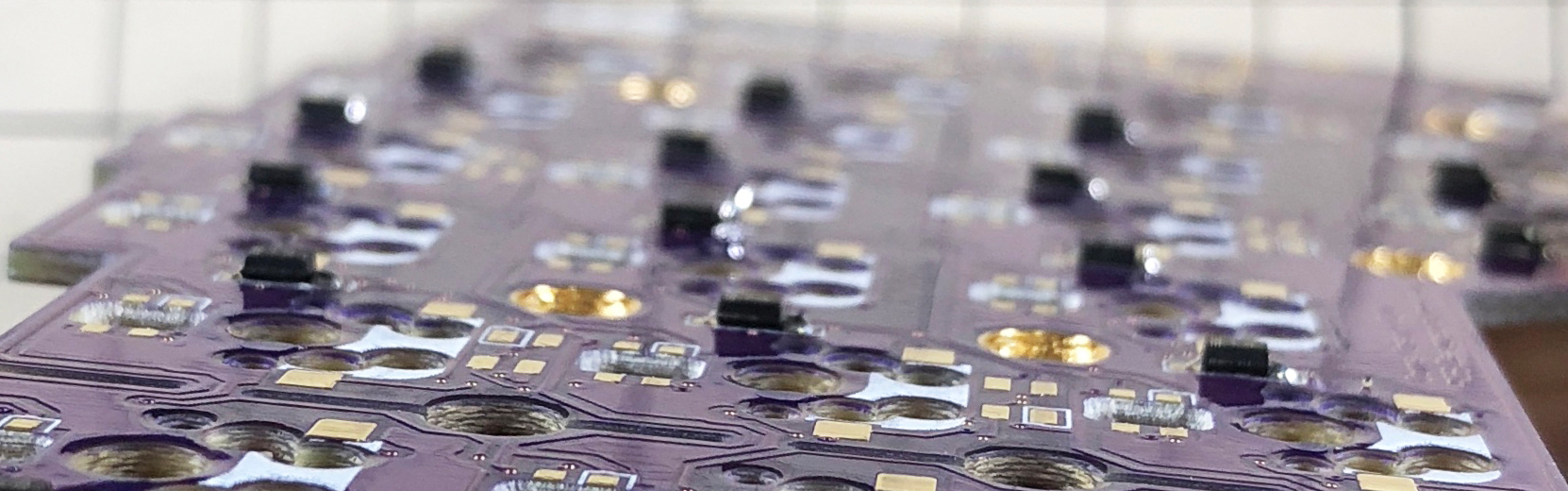

Fill the pads on both sides of the back with solder.

|

||||

It is difficult to add it later, so please add more in advance.

|

||||

|

||||

|

||||

|

||||

Insert the socket and attach it by melting the solder you have.

|

||||

At this time, hold it down with tweezers or your fingers

|

||||

so that the socket does not float.

|

||||

|

||||

|

||||

|

||||

Soldering is now complete.

|

||||

If you want to add an LED as an option,

|

||||

refer to the "LED" chapter below

|

||||

(it can be attached even after installing the socket).

|

||||

|

||||

|

||||

|

||||

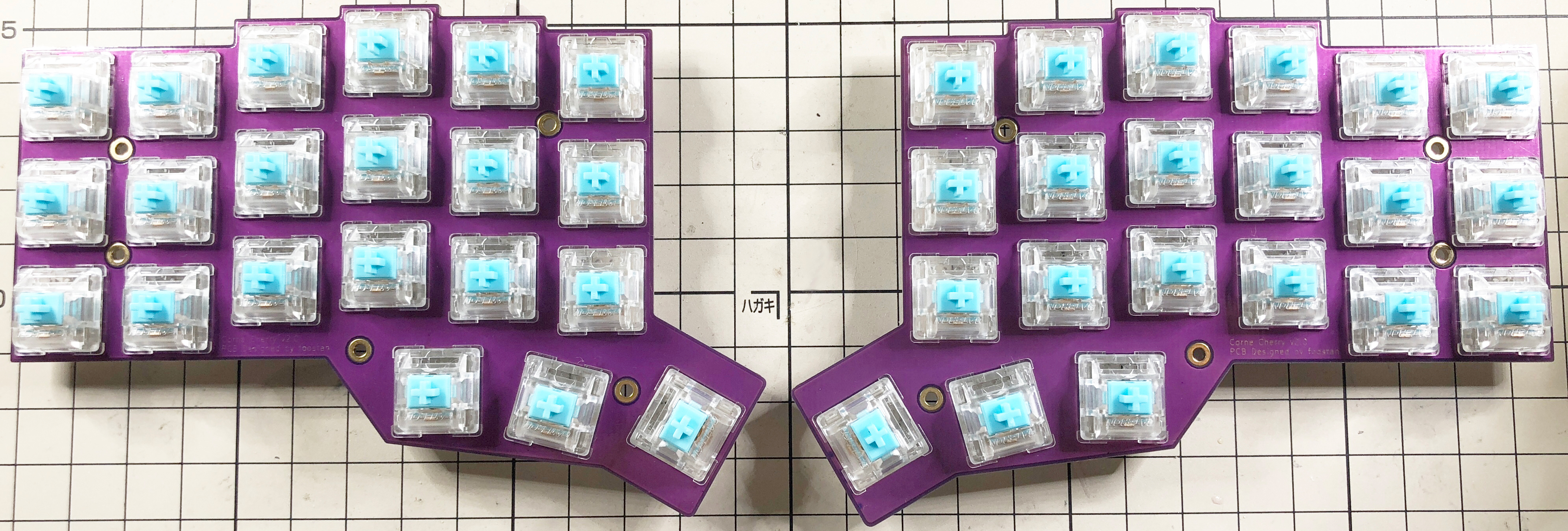

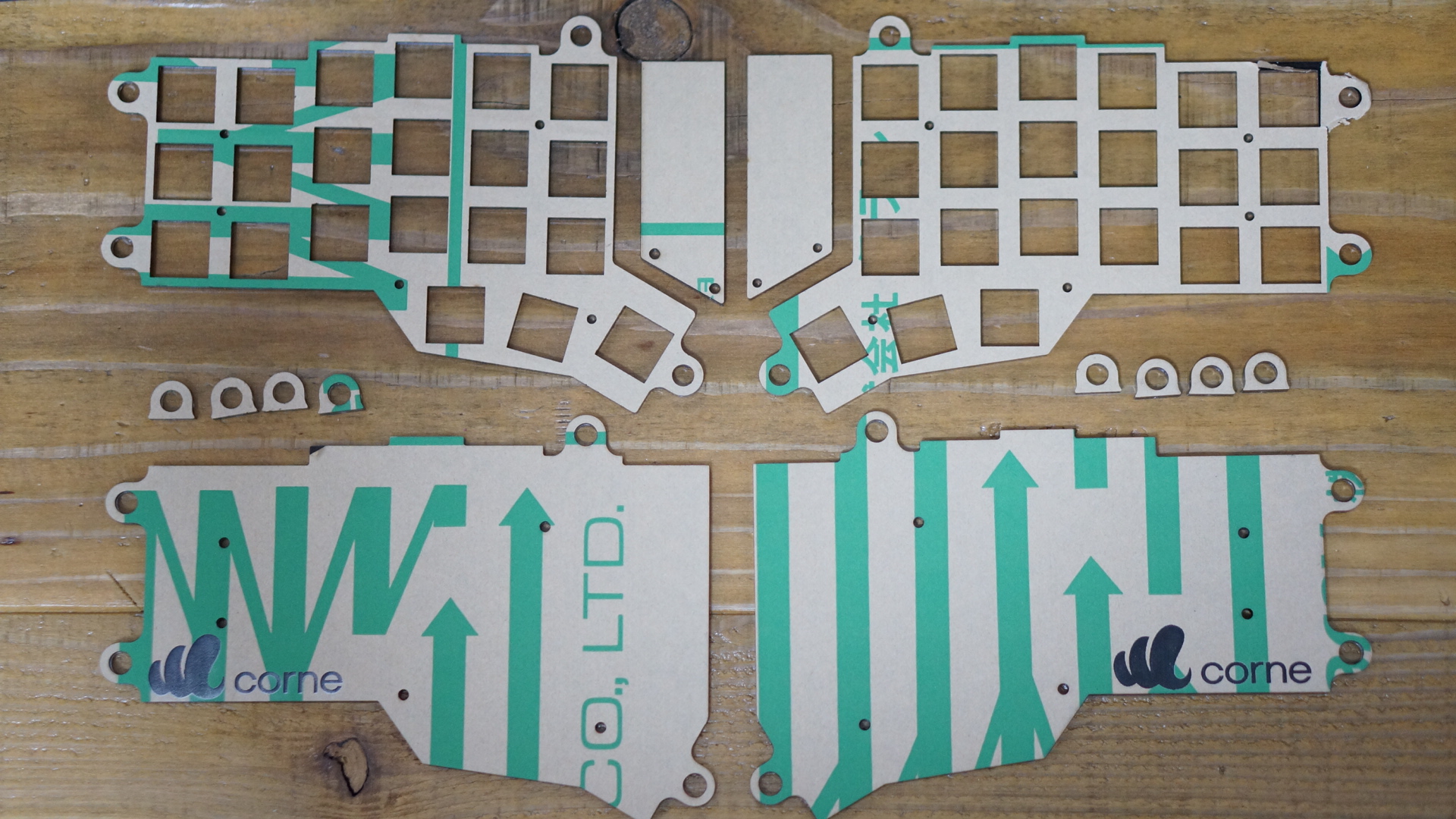

### Plates, switches

|

||||

|

||||

First, insert the switch into the top plate.

|

||||

It's okay to do it later, but it's easier to put it in first,

|

||||

because it's necessary to insert the switch from a little bit.

|

||||

|

||||

|

||||

|

||||

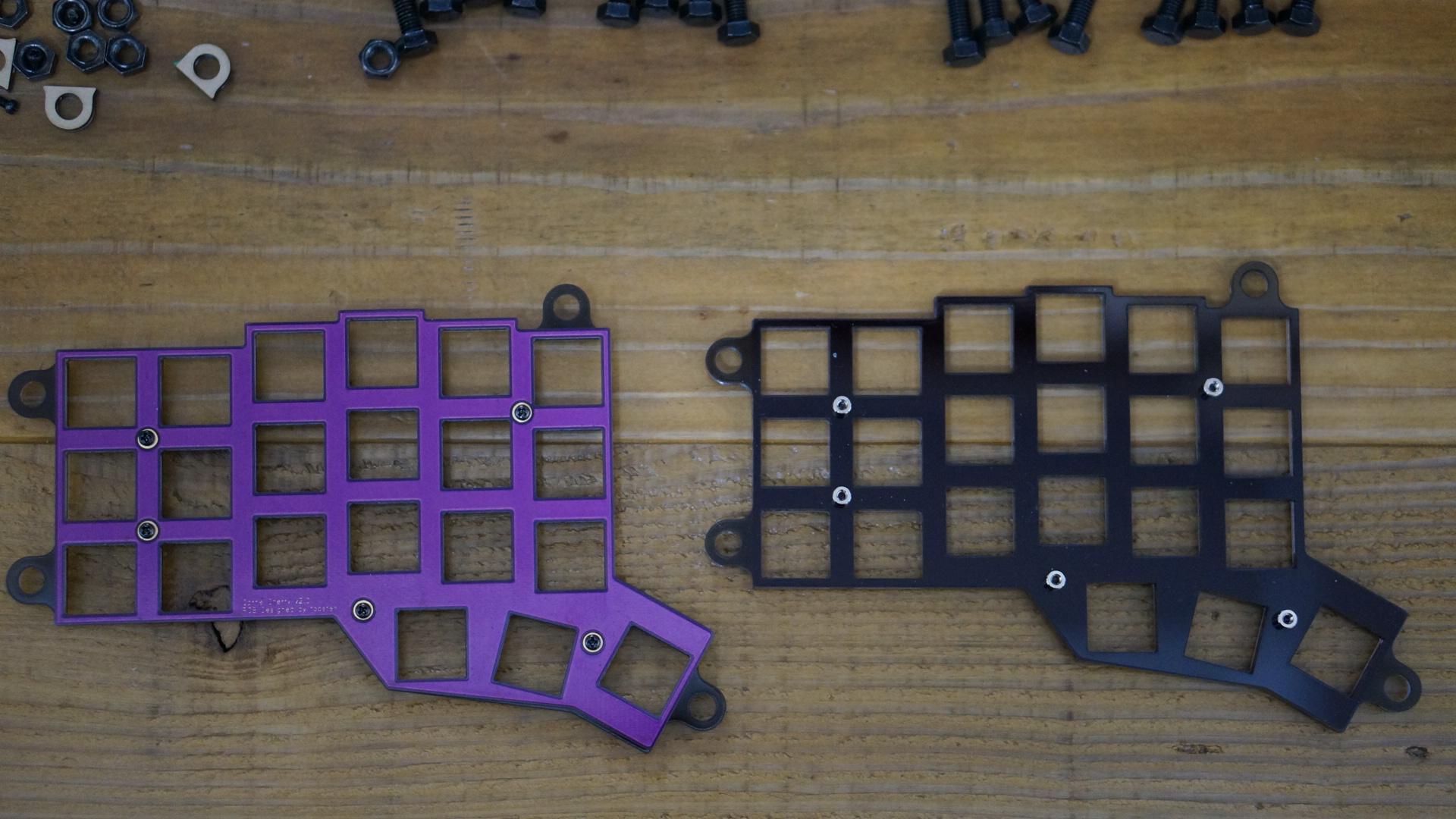

Finally, attach the spacers with screws so that the top plate, PCB,

|

||||

and bottom plate are in that order,

|

||||

and attach the cushion rubber to the four corners to complete the process.

|

||||

|

||||

|

||||

|

||||

## Firmware

|

||||

|

||||

Write the firmware to ProMicro by referring to the following. \

|

||||

<https://github.com/foostan/crkbd/blob/master/doc/firmware_en.md>

|

||||

|

||||

## LED (optional)

|

||||

|

||||

I will install the SK6812 MINI.

|

||||

|

||||

The SK6812MINI is extremely heat sensitive and breaks easily.

|

||||

We recommend using a soldering iron with a temperature control function

|

||||

and working at a temperature of 220°C to 270°C.

|

||||

Even if the temperature is adjusted,

|

||||

it will be damaged if the iron is applied to the LED for a long time,

|

||||

so try to solder as quickly as possible.

|

||||

The LEDs are soldered four by four,

|

||||

but it is recommended that you do not do four at a time,

|

||||

but two at a time to prevent the LED temperature from rising,

|

||||

as it will be less likely to break.

|

||||

|

||||

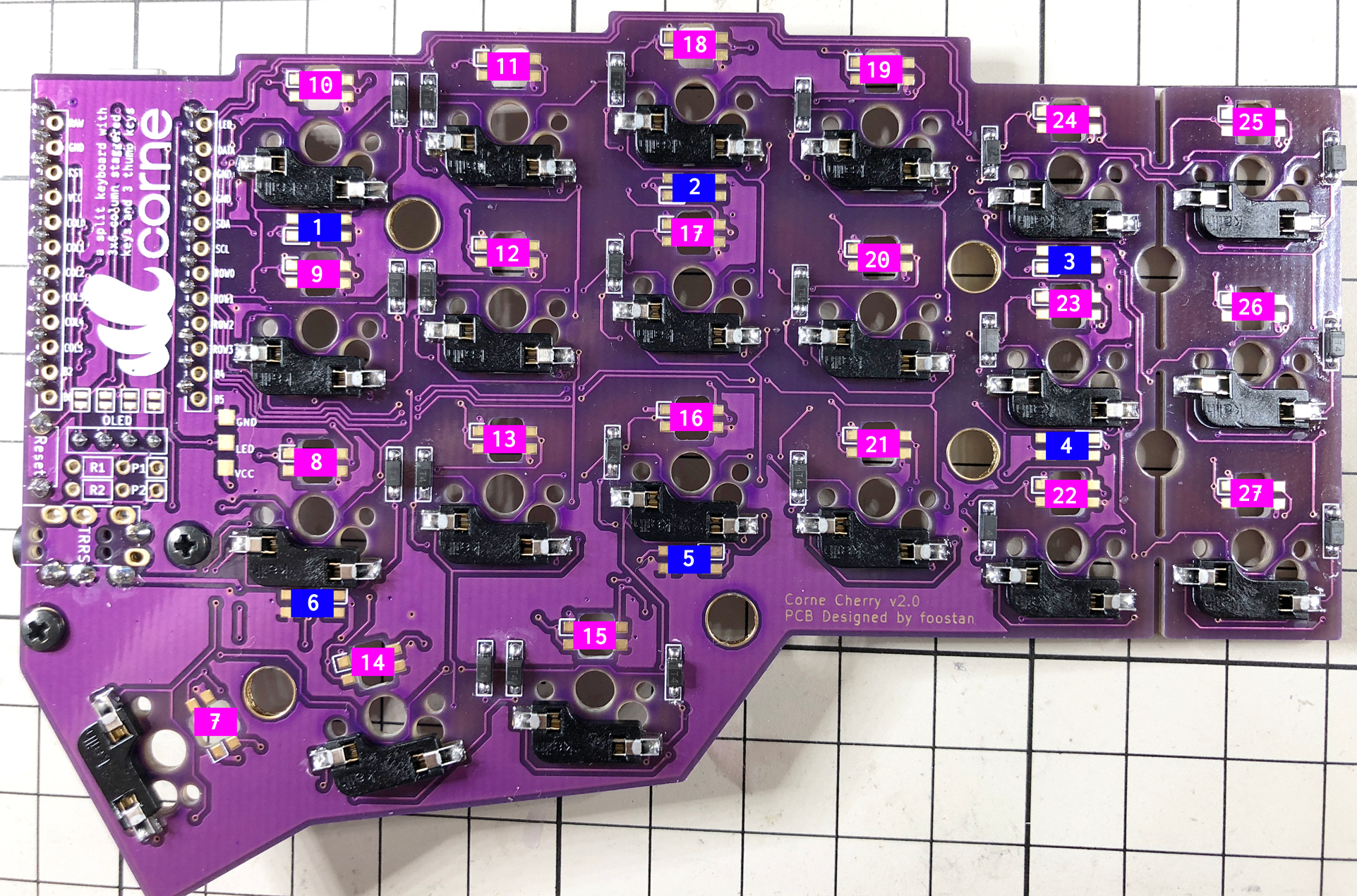

First, check the mounting position.

|

||||

|

||||

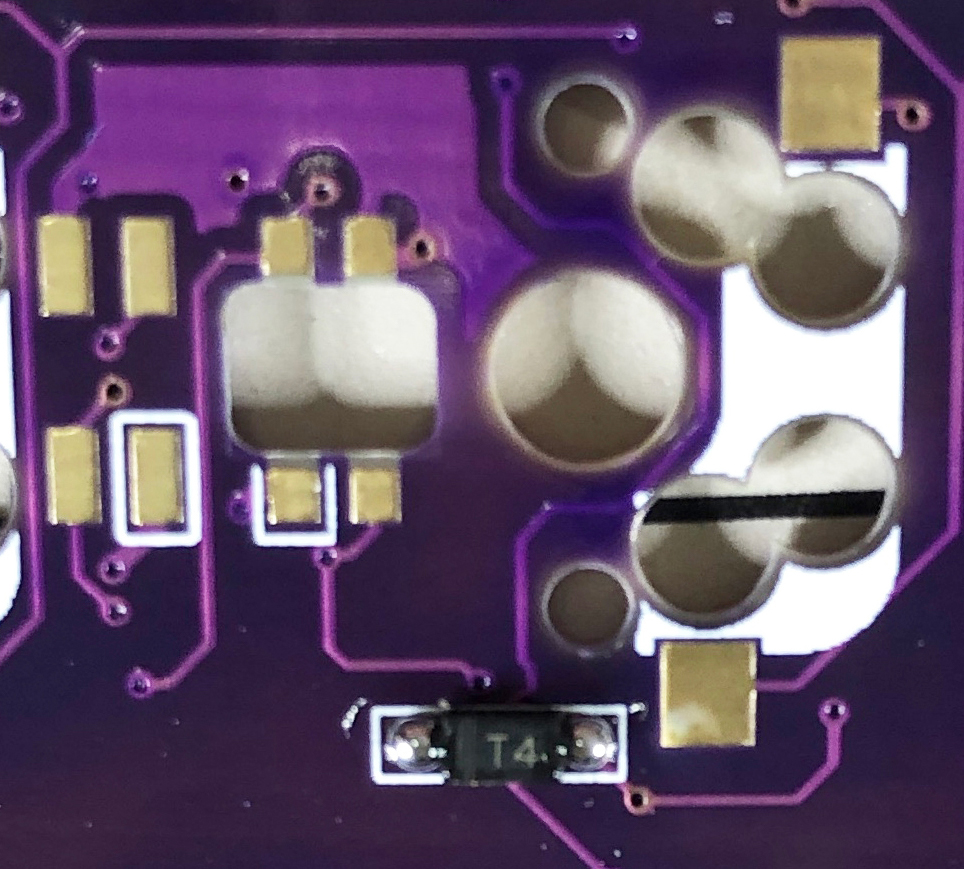

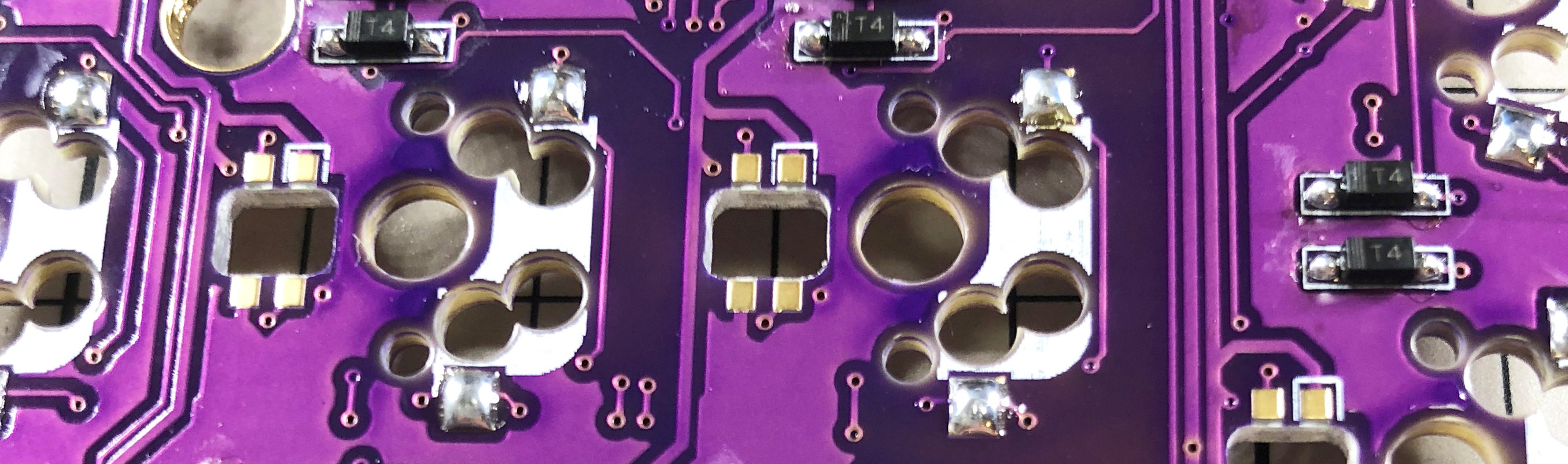

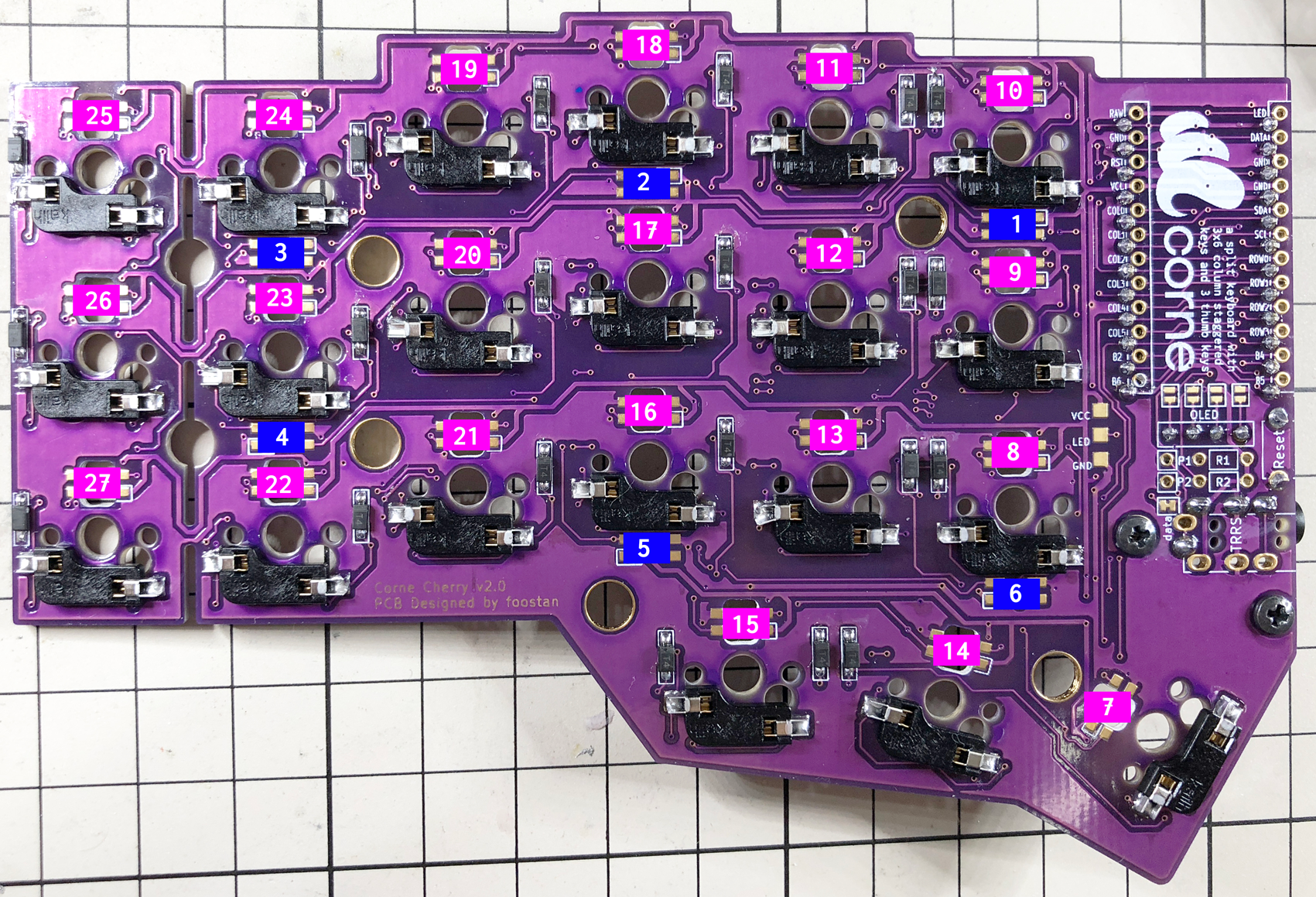

Solder 1 to 6 so that the back side (Undergrow) shines,

|

||||

and 7 to 27 so that the front side (Backlight) shines.

|

||||

Below is the position to install the LED.

|

||||

|

||||

|

||||

|

||||

|

||||

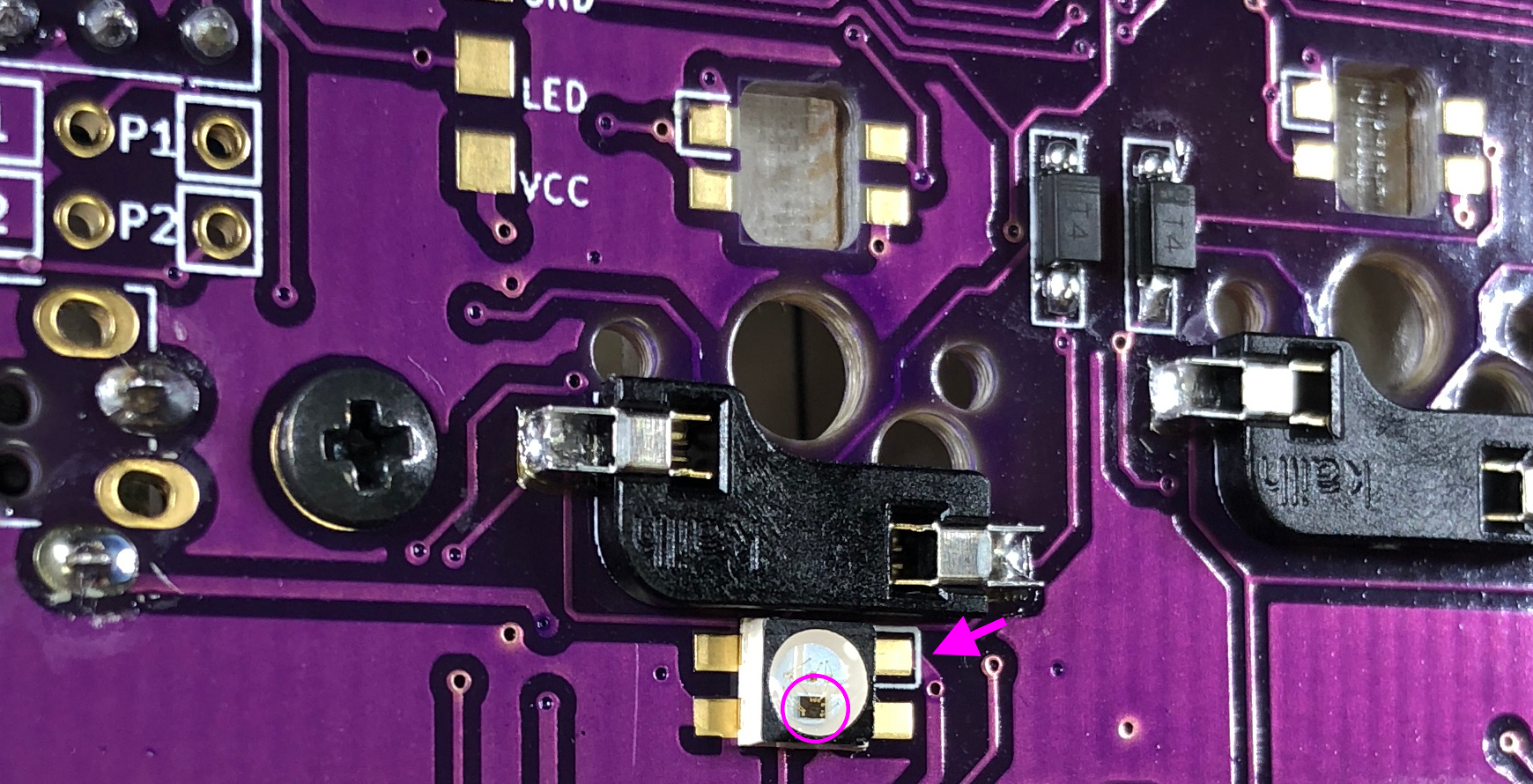

Solder 1 to 6 so that the black part circled as shown below is on the bottom

|

||||

and the silk mark indicated by the arrow is on the top.

|

||||

Please note that the orientation changes between 1 ~ 3 and 4 ~ 5.

|

||||

|

||||

|

||||

|

||||

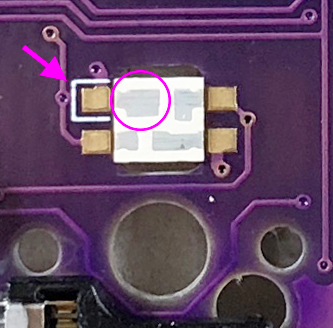

Solder 7 to 27 so that the largest pad circled

|

||||

and the silk mark indicated by the arrow are adjacent to each other,

|

||||

as shown below.

|

||||

|

||||

|

||||

|

||||

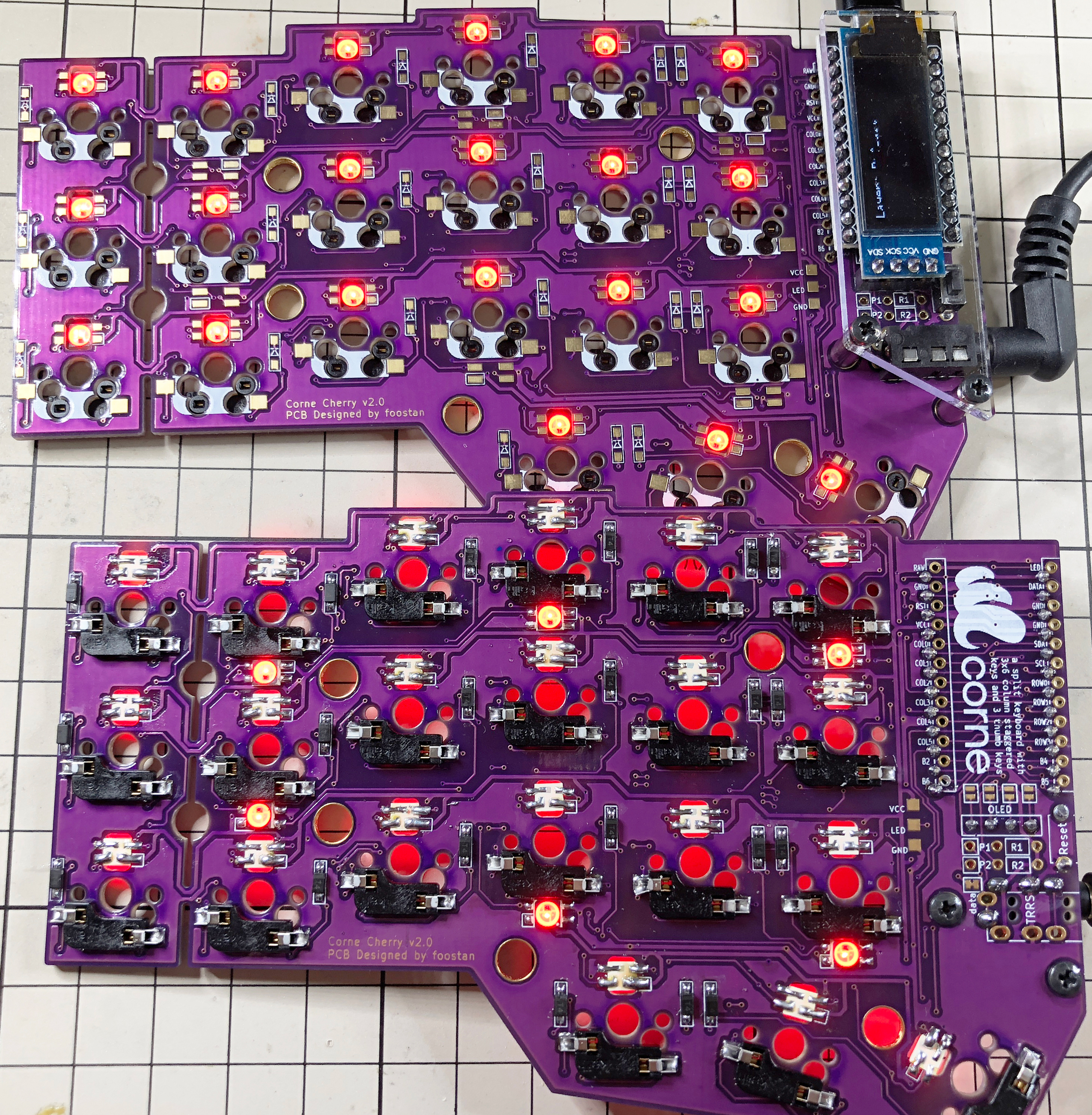

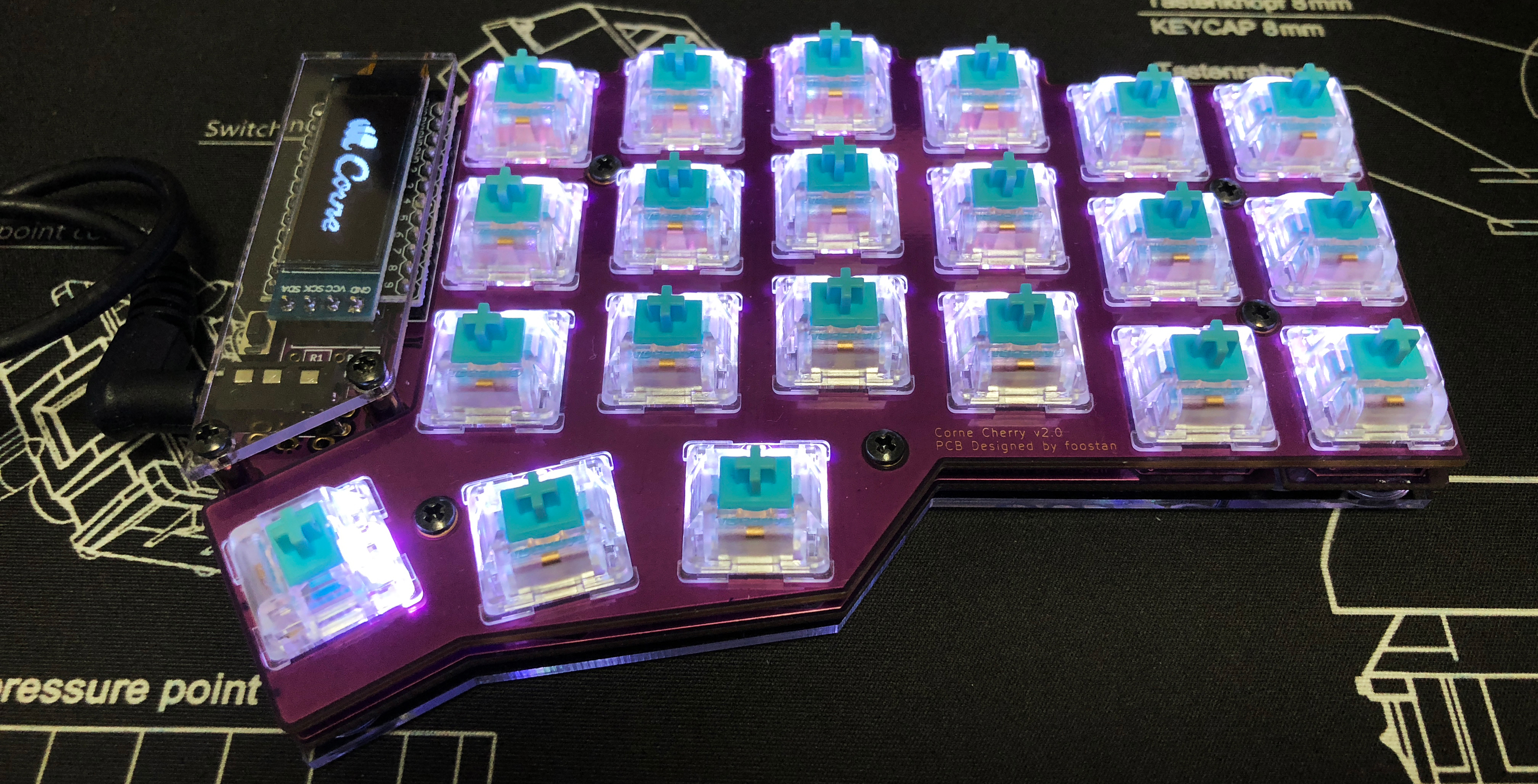

If everything can be soldered normally, it will shine as shown below.

|

||||

If it shines only halfway, the LEDs are connected in numerical order,

|

||||

so suspect that the LED that does not shine

|

||||

or the LED in front of it is soldered incorrectly or that the LED is damaged.

|

||||

|

||||

|

||||

|

||||

That's all there is to it.

|

||||

|

||||

|

||||

61

corne-cherry/doc/v2/buildguide_tilting_tenting_plate_en.md

Normal file

61

corne-cherry/doc/v2/buildguide_tilting_tenting_plate_en.md

Normal file

@@ -0,0 +1,61 @@

|

||||

# Build Guide Tilting / Tenting plate

|

||||

|

||||

## Parts

|

||||

|

||||

| Name | Number | Remarks |

|

||||

|:-|:-|:-|

|

||||

| Completed Corne Cherry | 1 set | Corne Chocolate / 3mm top plate is not supported |

|

||||

| Middle plate 3mm | 2 sheets | |

|

||||

| Bottom plate 3mm | 2 sheets | |

|

||||

| Bolt M5 15mm ~ 50mm | 8 bolts | |

|

||||

| Nut M5 | 16 pieces | |

|

||||

| Screw M2 6mm | 10 screws | |

|

||||

| Screw M2 4mm | 10 screws | |

|

||||

| Spacer M2 3.5mm | 10 pieces | |

|

||||

| Cushion rubber | 8 pieces | |

|

||||

|

||||

## Advance preparation

|

||||

|

||||

|

||||

|

||||

Remove the key switch from the finished Corne Cherry

|

||||

to separate the body from the top plate.

|

||||

No other parts are needed.

|

||||

|

||||

## Assembly

|

||||

|

||||

|

||||

|

||||

|

||||

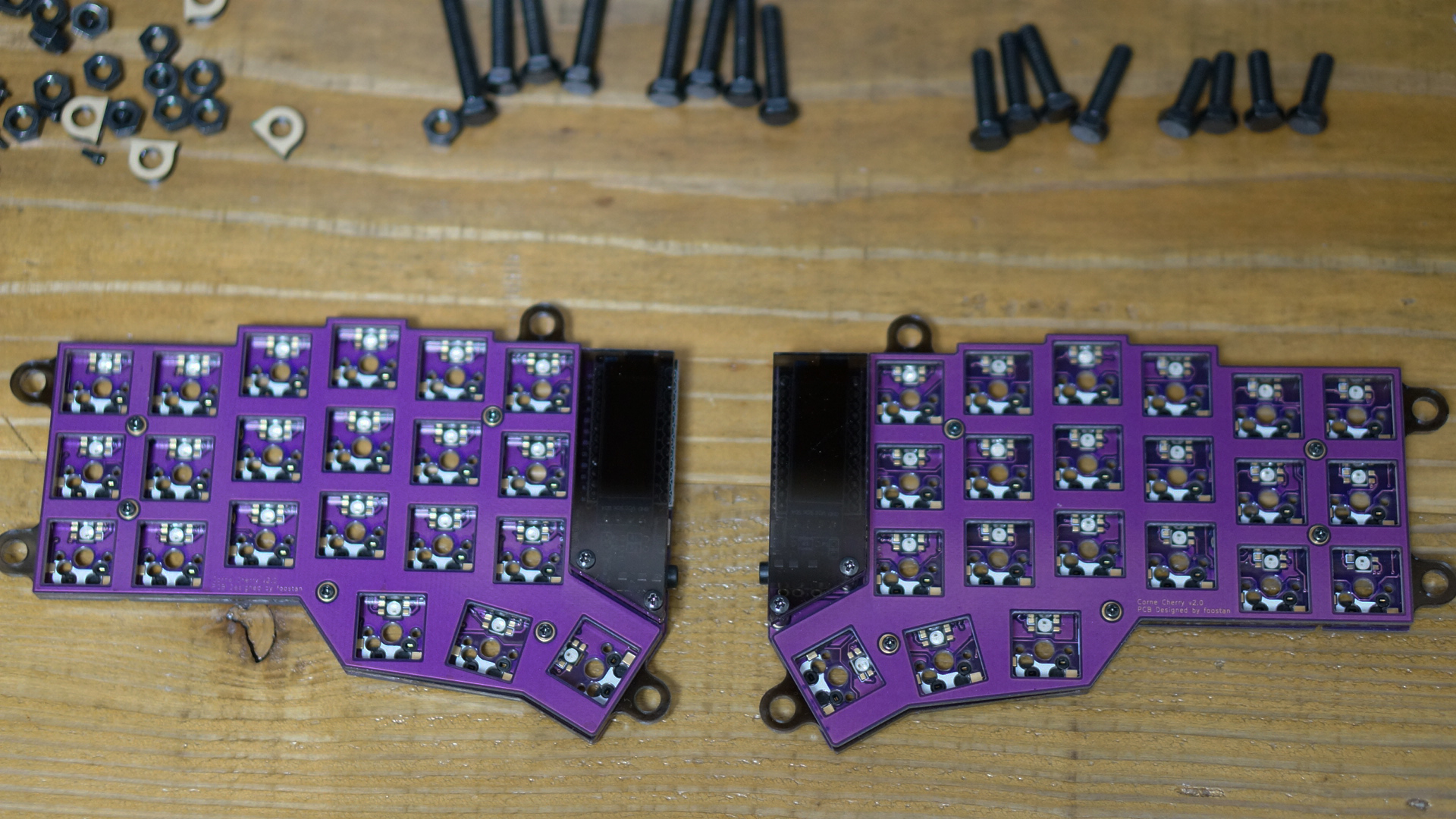

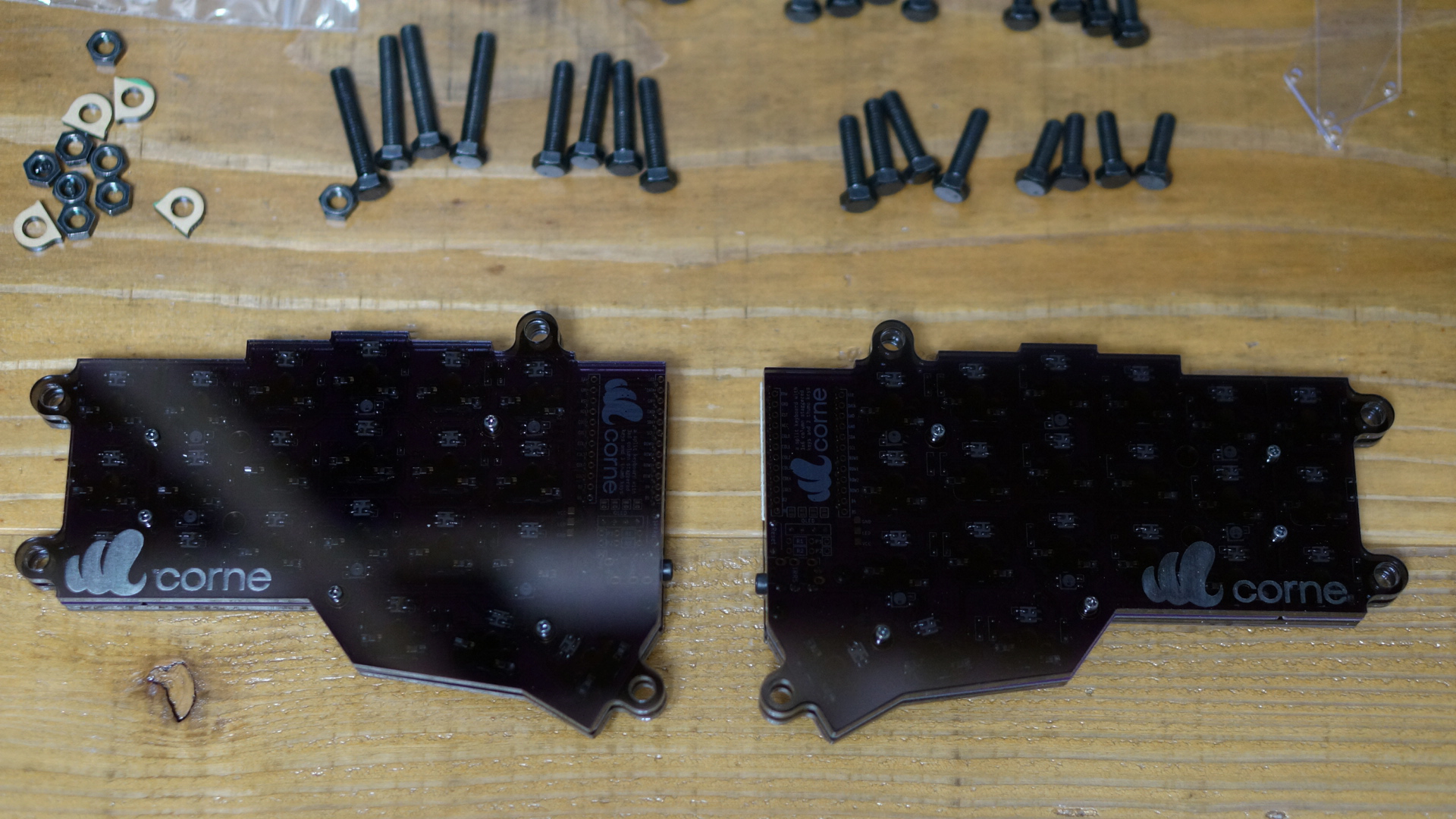

Check the required parts.

|

||||

Check the dedicated middle plate and bottom plate, and bolts of various lengths.

|

||||

In addition, use screws, nuts, spacers, etc. (see the parts section for details).

|

||||

|

||||

|

||||

|

||||

Secure the middle plate to the top plate with 6mm screws and 3.5mm spacers.

|

||||

|

||||

|

||||

Secure the OLED display protection plate with 4mm screws.

|

||||

|

||||

|

||||

|

||||

Secure the body and bottom plate with 4mm screws.

|

||||

|

||||

|

||||

|

||||

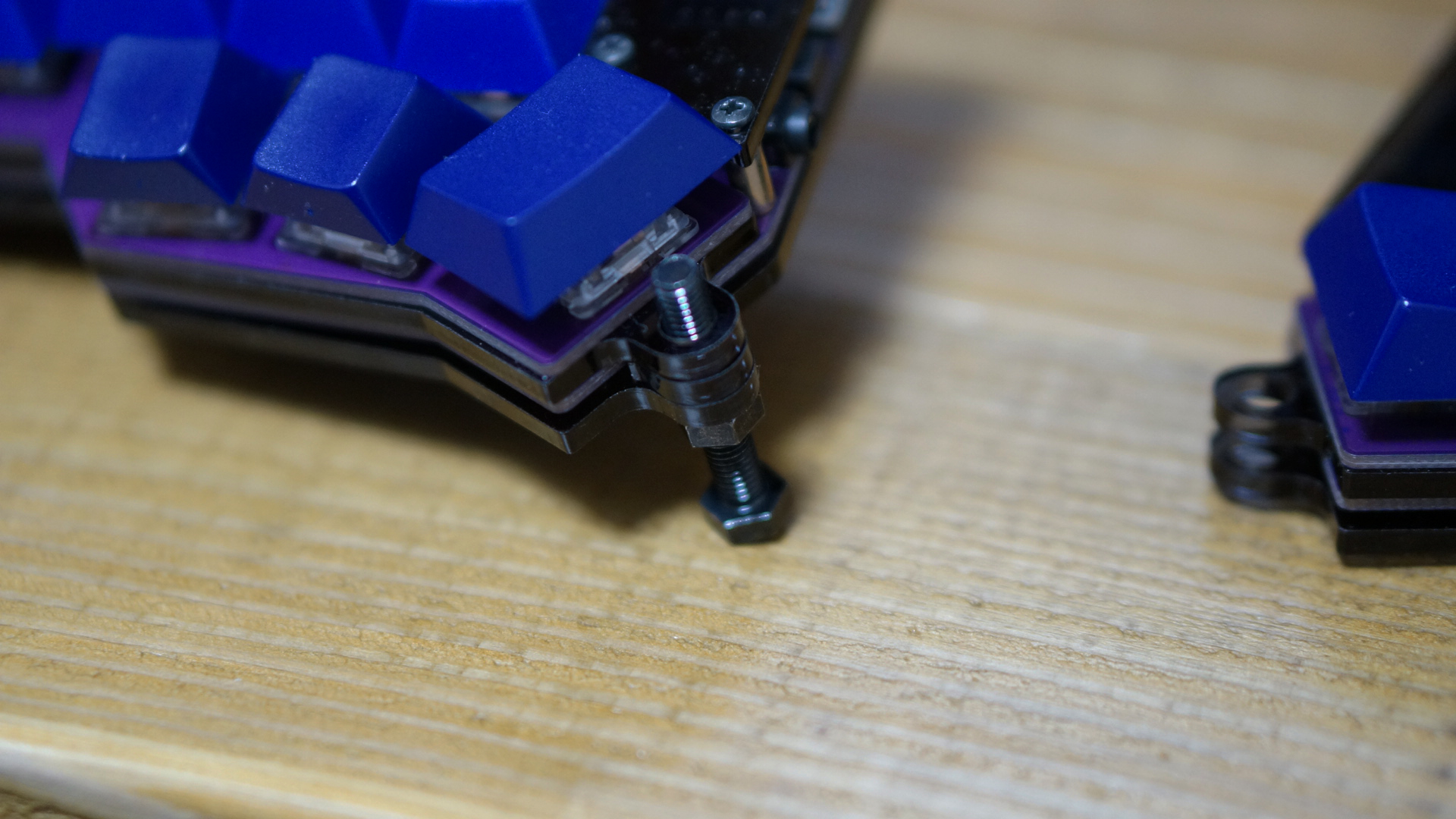

Insert an acrylic spacer between the middle plate

|

||||

and the bottom plate and attach the bolts.

|

||||

|

||||

|

||||

|

||||

It is recommended to temporarily assemble the bolts

|

||||

and adjust the height before completely fixing them with nuts.

|

||||

Temporary assembly can be done easily by passing only one nut through the bolt.

|

||||

|

||||

|

||||

|

||||

|

||||

It is completed by firmly fixing it so that it is sandwiched between nuts.

|

||||

|

||||

|

||||

Reference in New Issue

Block a user