update firmware reference + more build guide things

This commit is contained in:

@@ -11,32 +11,33 @@ https://github.com/foostan/crkbd/blob/master/corne-cherry/doc/v2/buildguide_en.m

|

|||||||

| Name | Count | Remarks |

|

| Name | Count | Remarks |

|

||||||

|:-|:-|:-|

|

|:-|:-|:-|

|

||||||

| PCB | 1 set | |

|

| PCB | 1 set | |

|

||||||

| Top plate | 2 sheets | |

|

| Top plate | 2 sheets | 1.5mm-3mm thick |

|

||||||

| Bottom plate | 2 sheets | |

|

| Bottom plate | 2 sheets | |

|

||||||

| OLED cover | 2 sheets | |

|

| OLED cover | 2 sheets | |

|

||||||

| ProMicro | 2 | |

|

| ProMicro | 2 | Alternative: [Elite-C](https://deskthority.net/wiki/Elite-C) |

|

||||||

| TRRS jack | 2 | |

|

| TRRS jack | 2 | |

|

||||||

| Reset switch | 2 | |

|

| Reset switch | 2 | |

|

||||||

| Diodes | 42 | Only SMD parts are supported |

|

| Diodes | 42 | SMD Only (SOD-123 Package) |

|

||||||

| PCB sockets | 42 | Compatible with Kailh and Gateron |

|

| PCB sockets | 42 | Compatible with Kailh and Gateron |

|

||||||

| Key switches | 42 | Only compatible with CherryMX |

|

| Key switches | 42 | Only compatible with MX style |

|

||||||

| Keycaps | 42 pcs | 1u 40 pcs, 1.5u 2 pcs |

|

| Keycaps | 42 pieces | 1u 40 pcs, 1.5u 2 pcs |

|

||||||

| Spacer M2 7.5mm | 10 pieces | |

|

| Spacer M2 7.5mm | 10 pieces | For Case assembly |

|

||||||

| Spacer M2 9mm | 4 pieces | |

|

| Spacer M2 9mm | 4 pieces | For OLED cover |

|

||||||

| Screw M2 4mm | 28 screws | |

|

| Screw M2 4mm | 28 screws | |

|

||||||

| Rubber feet | 8 pieces | |

|

| Rubber feet | 8 pieces | |

|

||||||

| TRRS (4 poles) cable | 1 | TRS (3 poles) cable is also acceptable |

|

| TRRS (4 poles) cable | 1 | TRS (3 poles) cable is also compatible |

|

||||||

| Micro USB cable | 1 | |

|

| Micro USB cable | 1 | Avoid charge-only cables |

|

||||||

|

|

||||||

### Optional

|

### Optional

|

||||||

|

|

||||||

| Name | Count | Remarks |

|

| Name | Count | Remarks |

|

||||||

|:-|:-|:-|

|

|:-|:-|:-|

|

||||||

| OLED module | 2 | |

|

| OLED module | 2 | |

|

||||||

| Pin header for OLED module 4 series 1.5mm | 2 | |

|

| SK6812MINI-E | 42 | LEDs for Backlight |

|

||||||

| 4 pin sockets for OLED module 2.5mm | 2 | |

|

|

||||||

| SK6812MINI-E | 42 pieces | LEDs for Back light |

|

|

||||||

| WS2812B | 12 | LEDs for Undergrow |

|

| WS2812B | 12 | LEDs for Undergrow |

|

||||||

|

| [Microcontroller/OLED Sockets](https://www.digikey.com/en/products/detail/315-43-112-41-003000/ED4764-12-ND/4455232) | 1 | Alternative: [2.54 1row femal sliv](https://www.aliexpress.com/item/4001122376295.html) option |

|

||||||

|

| [Microcontroller Pins](https://www.digikey.com/en/products/detail/mill-max-manufacturing-corp/3320-0-00-15-00-00-03-0/4147392) | 48 | Alternative: Diode/Resistor legs |

|

||||||

|

| [OLED Headers](https://www.digikey.com/en/products/detail/mill-max-manufacturing-corp/350-10-164-00-006000/357045) | 1 | Soldered to OLED module |

|

||||||

|

|

||||||

## Firmware preparation

|

## Firmware preparation

|

||||||

|

|

||||||

@@ -57,11 +58,11 @@ Make sure it is the same as your PCB.

|

|||||||

|

|

||||||

The PCB comes with a frame for manufacturing reasons.

|

The PCB comes with a frame for manufacturing reasons.

|

||||||

You can fold it by hand to remove it, but if it is difficult,

|

You can fold it by hand to remove it, but if it is difficult,

|

||||||

make a cut in the joint \* with a cutter or similar,

|

make a cut in the joint\* with a cutter or similar,

|

||||||

to make it easier to remove.

|

to make it easier to remove.

|

||||||

In addition, the joint can be cleaned with a file.

|

In addition, the joint can be cleaned with a file.

|

||||||

|

|

||||||

\* *Joint part: There are a total of 8 parts,

|

\**Joint part: There are a total of 8 parts,

|

||||||

which are marked in red in the image below.*

|

which are marked in red in the image below.*

|

||||||

|

|

||||||

|

|

||||||

@@ -70,50 +71,43 @@ which are marked in red in the image below.*

|

|||||||

|

|

||||||

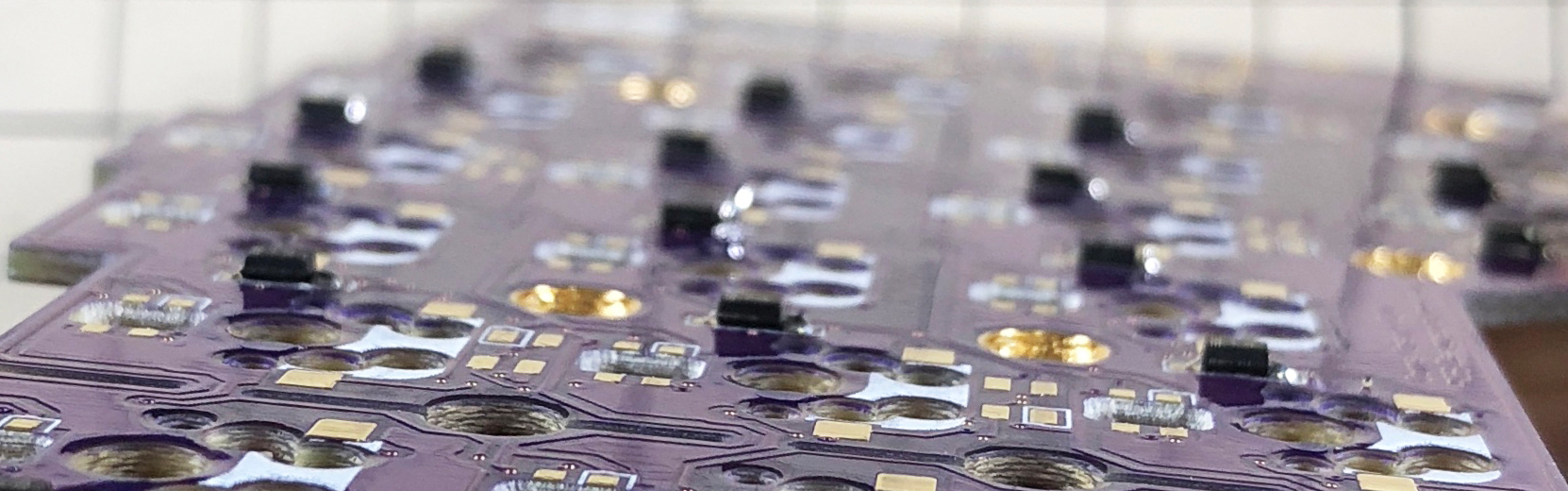

### Diodes

|

### Diodes

|

||||||

|

|

||||||

Solder diodes for SMD components.

|

Since SMD parts are very small, fine-tip/reverse-action tweezers are recommended.

|

||||||

Since SMD parts are very small,

|

|

||||||

it is convenient to have tweezers and counter-acting tweezers.

|

|

||||||

|

|

||||||

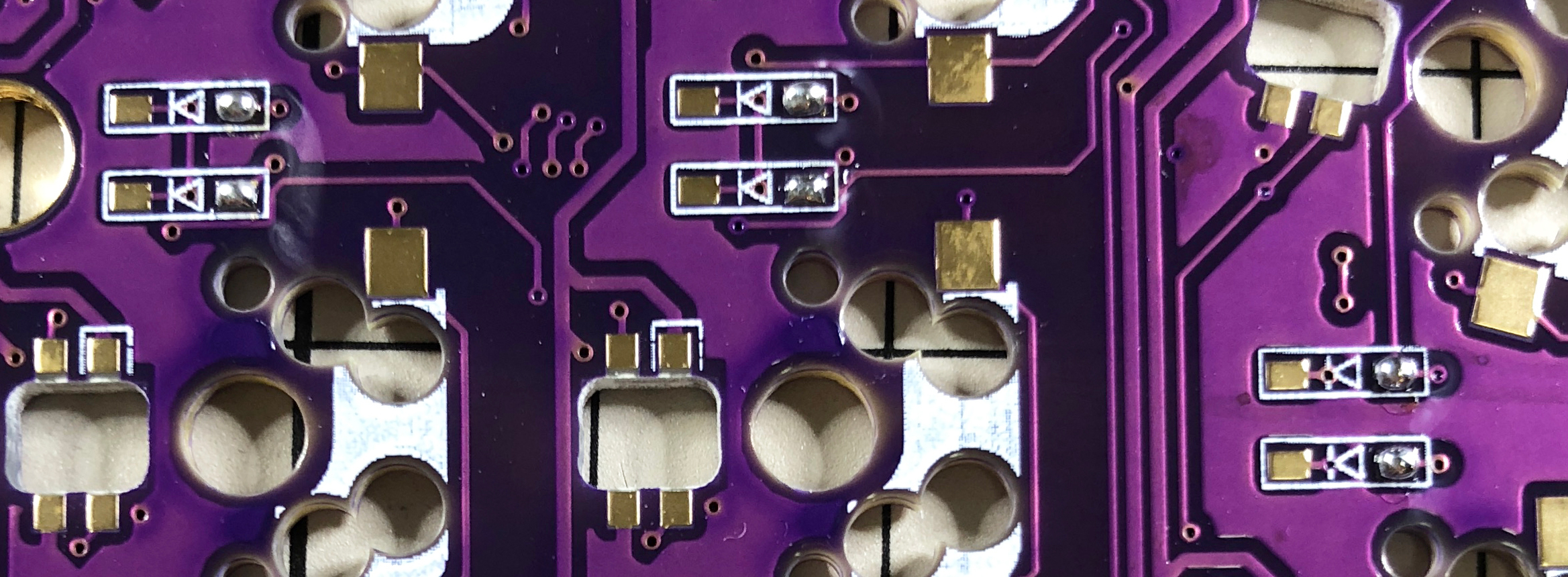

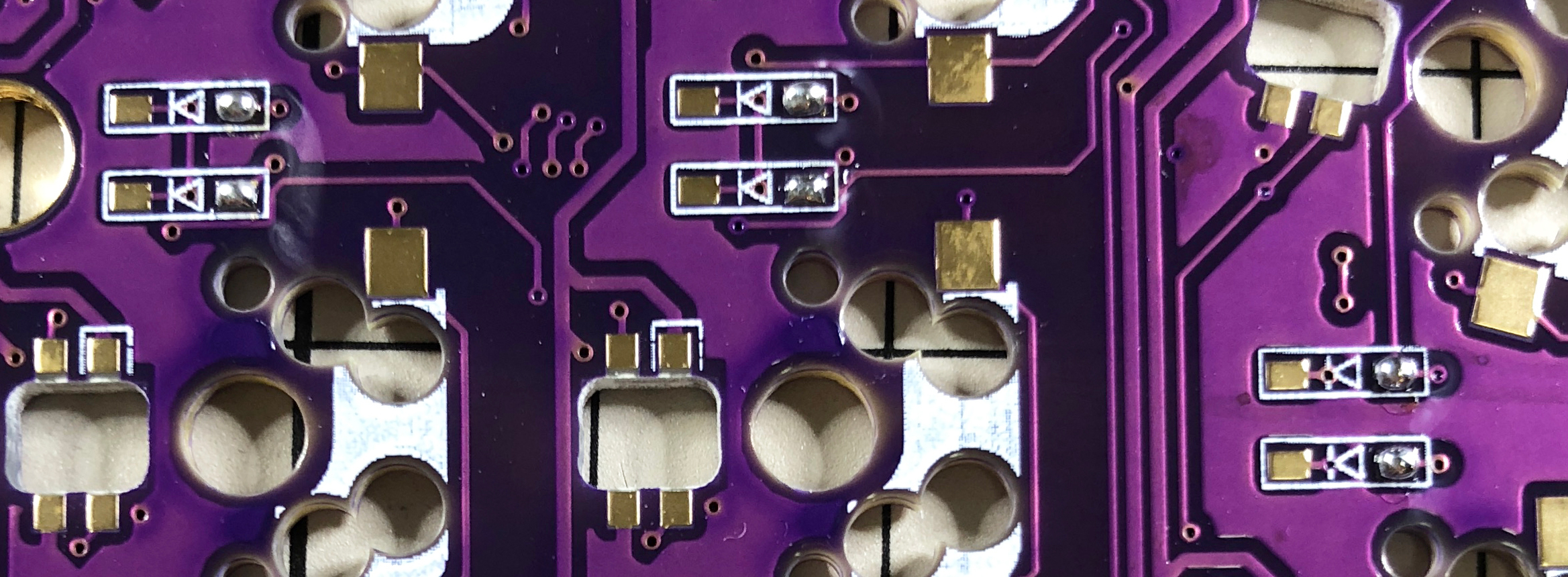

**The diode has a fixed mounting direction**,

|

**The diodes have a specific orientation**, so install with "|" marking on the diode

|

||||||

so solder it so that the "|" mark on the part faces the "|" on the diode mark "|◁".

|

facing the "|" on the PCB marking: "|◁"

|

||||||

In addition, Corne's PCB has all the same diode mounting orientations.

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

<details>

|

<details>

|

||||||

<summary>TIPS: Tips for installing SMD parts</summary>

|

<summary>TIPS: Tips for installing SMD parts</summary>

|

||||||

|

|

||||||

The trick is to attach the SMD parts, but first, as a spare solder,

|

Begin with applying solder to only one pad.

|

||||||

put the solder on only one side of the pad.

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Next, solder one leg of the diode so that the spare solder melts.

|

Next, place SMD component while heating solder. At this time,

|

||||||

At this time,

|

|

||||||

it is recommended to use [reverse-action tweezers](https://www.alimed.com/_resources/cache/images/product/70895A_850x480-pad.jpg),

|

it is recommended to use [reverse-action tweezers](https://www.alimed.com/_resources/cache/images/product/70895A_850x480-pad.jpg),

|

||||||

so that you can hold the SMD part firmly without applying force,

|

so that you can hold the SMD part firmly without applying force,

|

||||||

and concentrate on alignment and soldering instead.

|

and concentrate on alignment and soldering instead.

|

||||||

Also, if the soldering iron is too hot or the solder is touched too long,

|

Also, if the soldering iron is too hot or the solder is touched too long,

|

||||||

the flux contained in the solder may evaporate and form an undesirable pile solder,

|

the flux contained in the solder may evaporate and form a poor solder joint,

|

||||||

but since it can be repaired later,

|

but it can be repaired later,

|

||||||

so at this point you should only care about attaching parts.

|

so at this point you should only care about attaching parts.

|

||||||

It's okay.

|

It's okay.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

It is okay if the diode does not float when viewed from the side

|

It is okay if the SMD component is not flush with the PCB when viewed from the side.

|

||||||

when one foot is attached.

|

If it is floating, press the SMD component down with tweezers or your finger and reheat the solder.

|

||||||

If it floats, press the diode with tweezers or your fingers

|

|

||||||

and reheat the soldered part with a soldering iron to clean it.

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Then solder the other pin.

|

Then solder the other contacts.

|

||||||

Be careful not to apply too much solder,

|

Be careful not to apply too much solder,

|

||||||

as a small amount is sufficient.

|

as a small amount is sufficient.

|

||||||

If you have applied too much,

|

If you have applied too much,

|

||||||

you can remove it with a suction pump, blotting wire

|

you can remove it with a suction pump, solder wick,

|

||||||

or by scooping it with a soldering iron.

|

or by picking it up with a soldering iron.

|

||||||

|

|

||||||

If the amount of solder on the preliminary solder side is small,

|

If the amount of solder on the preliminary solder side is small,

|

||||||

additional soldering is performed, and if it is a heap,

|

additional soldering is performed, and if it is a heap,

|

||||||

@@ -131,28 +125,24 @@ The diode is completed by soldering 42 pieces in total on the left and right.

|

|||||||

|

|

||||||

Solder the SK6812MINI-E and WS2812B.

|

Solder the SK6812MINI-E and WS2812B.

|

||||||

|

|

||||||

First, check the state after installation.

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

All soldering is done from the back side, but the SK6812MINI-E is for Backlight

|

All soldering is done from the back side, but the SK6812MINI-E is for Backlight

|

||||||

(the front side is shining) and the WS2812B is for Undergrow (the back side is shining).

|

(the front side is shining) and the WS2812B is for Undergrow (the back side is shining).

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

#### WS2812B (Undergrow)

|

#### WS2812B (Undergrow)

|

||||||

|

|

||||||

First, solder the WS2812B.

|

First, solder the WS2812B.

|

||||||

|

|

||||||

Solder with the corners of the recesses on the WS2812B

|

Match recessed corner of the LED with marked corner on the PCB as shown below.

|

||||||

and the corner marks on the PCB aligned as shown below.

|

Refer to **TIPS: Tips for installing SMD parts** section above as similar soldering

|

||||||

**TIPS: As I introduced in Tips for Installing SMD Parts**,

|

procedure is followed.

|

||||||

I think that you can attach it well with spare solder.

|

|

||||||

|

|

||||||

In addition, his PCB of Corne has the same mounting orientation of his WS2812B.

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

He soldered a total of 12 pieces on the left and right, and he completed the WS2812B.

|

WS2812B LED soldering is completed after 12 are installed on left and right.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

@@ -160,21 +150,17 @@ He soldered a total of 12 pieces on the left and right, and he completed the WS2

|

|||||||

|

|

||||||

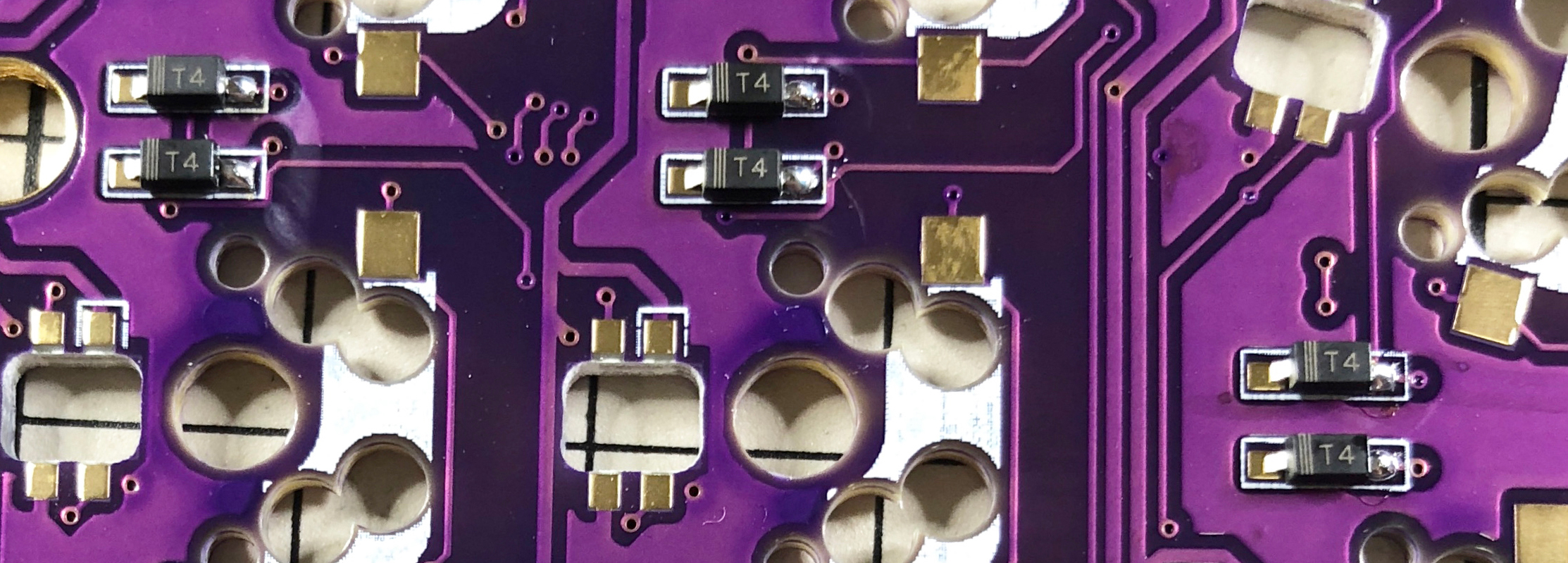

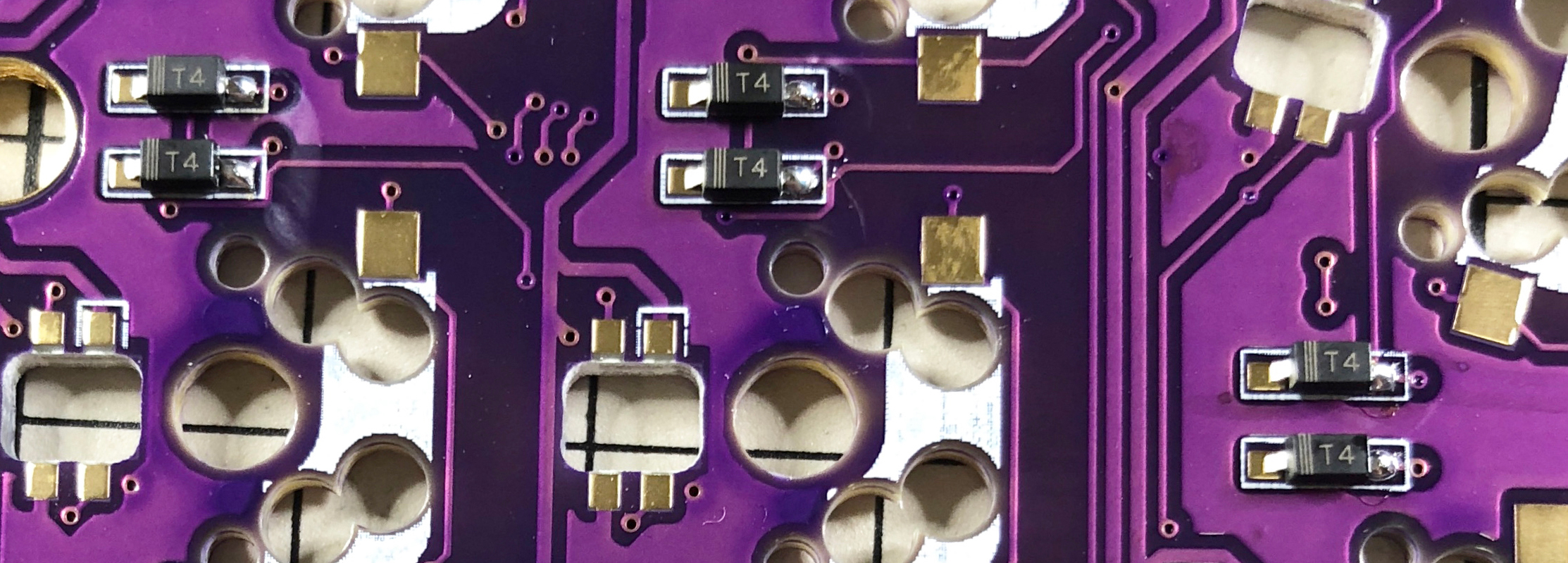

Then solder the SK6812MINI-E.

|

Then solder the SK6812MINI-E.

|

||||||

|

|

||||||

Solder the SK6812MINI-E with the missing corners aligned with the PCB corners

|

Match the notched corner of the LED with the marked corner on the PCB as show below.

|

||||||

as shown below.

|

Refer to **TIPS: Tips for installing SMD parts** section above as similar soldering

|

||||||

**TIPS: As I introduced in Tips for Installing SMD Parts**,

|

procedure is followed.

|

||||||

I think that you can attach it well with spare solder.

|

These are more resilient than the SK6812MINI LEDs,

|

||||||

It is harder to break than the SK6812MINI,

|

but still may be damaged if directly exposed to the heat of a soldering iron.

|

||||||

but it may be damaged if it is directly exposed to the heat of a soldering iron.

|

~320°C seems to be an ok temperature, evne if all four legs are soldered

|

||||||

If the temperature is about 320°C

|

one after another.

|

||||||

with a soldering iron with a temperature control function,

|

|

||||||

it seems that there is no problem even if four legs are soldered continuously.

|

|

||||||

|

|

||||||

All Corne PCBs have the same mounting orientation for the SK6812MINI-E.

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

SK6812MINI-E is completed by soldering a total of 42 pieces on the left and right.

|

SK6812MINI-E LED soldering is completed after 42 are installed on left and right.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

@@ -185,17 +171,15 @@ and OLED pin socket as shown in the picture below.

|

|||||||

|

|

||||||

|

|

||||||

|

|

||||||

Since it is a part that easily slips off,

|

Since these parts may fall off when soldering, you can affix them with masking tape.

|

||||||

you can solder it while holding the part by hand,

|

|

||||||

or fix it with masking tape and then solder it.

|

|

||||||

|

|

||||||

### ProMicro

|

### ProMicro

|

||||||

|

|

||||||

Solder headers to PCB. Then solder ProMicro to headers, with components facing PCB

|

Solder headers to PCB. Then solder ProMicro to headers, with components facing PCB as shown below.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

If you use spring-loaded pin headers (e.g. Conthrough),

|

If you use [spring-loaded pin headers](https://shop.yushakobo.jp/collections/all-keyboard-parts/products/31),

|

||||||

you do not need to solder the back side.

|

you do not need to solder the back side.

|

||||||

Please refer to the [Helix Build Guide](

|

Please refer to the [Helix Build Guide](

|

||||||

https://github.com/MakotoKurauchi/helix/blob/master/Doc/buildguide_en.md#pro-micro)

|

https://github.com/MakotoKurauchi/helix/blob/master/Doc/buildguide_en.md#pro-micro)

|

||||||

@@ -205,64 +189,55 @@ for details on how to use spring-loaded pin headers.

|

|||||||

|

|

||||||

### OLED module

|

### OLED module

|

||||||

|

|

||||||

Insert the pin header into the pin socket for OLED first,

|

Insert the pin header into the socket first, then solder the OLED module

|

||||||

and then solder the pin header and OLED module.

|

to the pin header.

|

||||||

At this time, the OLED module is easy to float,

|

Note: Solder one pin to OLED module, then reheat solder to confirm OLED module is level,

|

||||||

so be careful not to float it while pressing it with your finger.

|

then solder remaining pins.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

### Operation check

|

### Operation check

|

||||||

|

|

||||||

We recommend that you check the operation when the ProMicro and OLED module are attached.

|

Now is a good time to test your keyboard to help isolate potential problems.

|

||||||

If you do it at the very end, it will be difficult to isolate the problem.

|

|

||||||

|

|

||||||

To check the operation,

|

To check the operation, connect left and right sides with TRRS cable,

|

||||||

connect the left hand side to the PC with MicroUSB,

|

then connect left side to the computer with USB cable.

|

||||||

and connect the left hand side and the right hand side with the TRRS cable.

|

If it is done correctly so far, shorting a hotswap socket pad with tweezers will

|

||||||

Since there may be defects such as jacks,

|

output out a keypress and it will be displayed on the OLED module.

|

||||||

be sure to connect the left and right instead of one by one

|

|

||||||

before checking the operation.

|

|

||||||

If it is done correctly so far,

|

|

||||||

if you short the pad to attach the PCB socket with tweezers etc.,

|

|

||||||

the key pressed on the OLED module will be displayed.

|

|

||||||

|

|

||||||

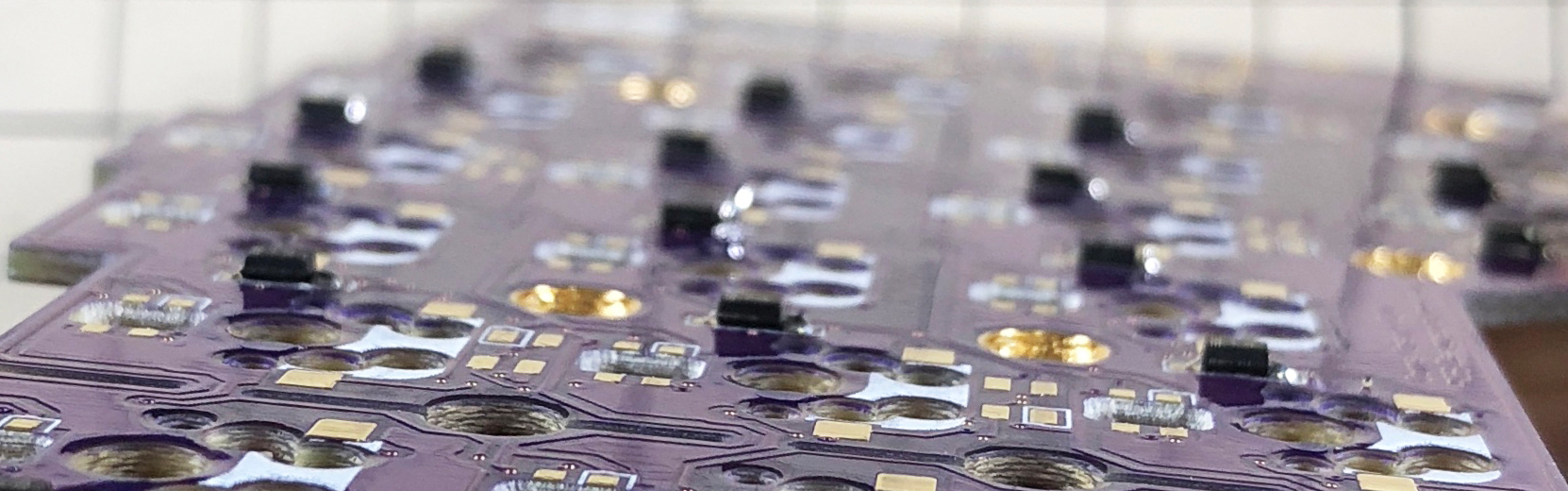

### PCB socket

|

### Switch Sockets

|

||||||

|

|

||||||

Solder the PCB socket according to the mark as shown below.

|

Solder hotswap sockets according to mark on PCB as shown below.

|

||||||

All the PCB sockets are listed below,

|

Refer to **TIPS: Tips for installing SMD parts** section above as similar soldering

|

||||||

but I'm not really into it,

|

procedure is followed.

|

||||||

so attach them one by one.

|

|

||||||

**TIPS: As I introduced in Tips for Installing SMD Parts**,

|

|

||||||

I think that you can attach it well with spare solder.

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

The PCB socket is completed by soldering a total of 42 left and right.

|

Switch Socket soldering is completed after 42 are installed on left and right.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

### OLED protective plate

|

### OLED protective cover

|

||||||

|

|

||||||

Attach the OLED protective plate with M2 9mm spacers and M2 screws.

|

Attach the OLED protective cover with M2 9mm spacers and M2 screws.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

### Plates, switches

|

### Plates & Switches

|

||||||

|

|

||||||

After attaching the key switch to the top plate,

|

Place a few key switches into the top plate, then line up and press into PCB socket.

|

||||||

fit the key switch into the socket.

|

|

||||||

If you attach all the key switches to the top plate first,

|

If you attach all the key switches to the top plate first,

|

||||||

it will be more difficult to fit them in the socket,

|

it will be more difficult to fit them in the PCB sockets all at once.

|

||||||

so it is easier to attach only the end key switches first.

|

So it is recommended to do a few to begin with.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

Install the M2 7.5mm spacer and M2 screws on the top plate.

|

Install the M2 7.5mm spacer and M2 screws on the top plate.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

It is easy to screw the spacer after inserting it into the hole from the back side.

|

It is easy to screw the spacer in after inserting it into the hole from the back side.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

@@ -270,10 +245,10 @@ Attach the bottom plate with M2 screws.

|

|||||||

|

|

||||||

|

|

||||||

|

|

||||||

Install the cushion rubber in the following positions.

|

Install the rubber feet in the following positions.

|

||||||

|

|

||||||

|

|

||||||

|

|

||||||

That's it.

|

That's it!

|

||||||

|

|

||||||

|

|

||||||

|

|||||||

File diff suppressed because it is too large

Load Diff

@@ -22,7 +22,7 @@ Open QMK Toolbox, you will see a window like the one below.

|

|||||||

### Flash the firmware

|

### Flash the firmware

|

||||||

|

|

||||||

Download the firmware of VIA from the following link.\

|

Download the firmware of VIA from the following link.\

|

||||||

[crkbd_rev1_common_via.hex](https://raw.githubusercontent.com/foostan/crkbd/main/doc/assets/crkbd_rev1_via.hex)

|

[crkbd_rev1_common_via.hex](https://raw.githubusercontent.com/foostan/qmk_firmware-hex/main/.build/crkbd_rev1_via.hex)

|

||||||

|

|

||||||

Specify the file downloaded from "**Open**" in QMK Toolbox.

|

Specify the file downloaded from "**Open**" in QMK Toolbox.

|

||||||

And enable the check box for "**Auto-Flash**".

|

And enable the check box for "**Auto-Flash**".

|

||||||

|

|||||||

@@ -21,7 +21,7 @@ QMK Toolbox を開くと下記のようなウィンドウが表示されます

|

|||||||

### ファームウェアの書き込み

|

### ファームウェアの書き込み

|

||||||

|

|

||||||

VIA用のファームウェアを下記よりダウンロードします。\

|

VIA用のファームウェアを下記よりダウンロードします。\

|

||||||

[crkbd_rev1_common_via.hex](https://raw.githubusercontent.com/foostan/crkbd/main/doc/assets/crkbd_rev1_via.hex)

|

[crkbd_rev1_common_via.hex](https://raw.githubusercontent.com/foostan/qmk_firmware-hex/main/.build/crkbd_rev1_via.hex)

|

||||||

|

|

||||||

QMK Toolbox の 「**Open**」 からダウンロードしたファイルを指定します。\

|

QMK Toolbox の 「**Open**」 からダウンロードしたファイルを指定します。\

|

||||||

また「**Auto-Flash**」のチェックボックスをチェックします。

|

また「**Auto-Flash**」のチェックボックスをチェックします。

|

||||||

|

|||||||

Reference in New Issue

Block a user