2019-12-27 18:44:33 +01:00

|

|

|

# Build Guide

|

|

|

|

|

|

|

|

|

|

This is the build guide for Corne Chocolate.

|

2021-05-15 11:20:11 +02:00

|

|

|

[Click here for the Corne Cherry build guide](

|

2021-04-17 15:09:15 +02:00

|

|

|

https://github.com/foostan/crkbd/blob/master/corne-cherry/doc/buildguide_en.md).

|

2020-07-07 09:57:59 +02:00

|

|

|

|

|

|

|

|

## Parts

|

|

|

|

|

|

|

|

|

|

### Required

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2021-05-15 08:51:41 +02:00

|

|

|

| Name | Count | Remarks |

|

2019-12-27 18:44:33 +01:00

|

|

|

|:-|:-|:-|

|

|

|

|

|

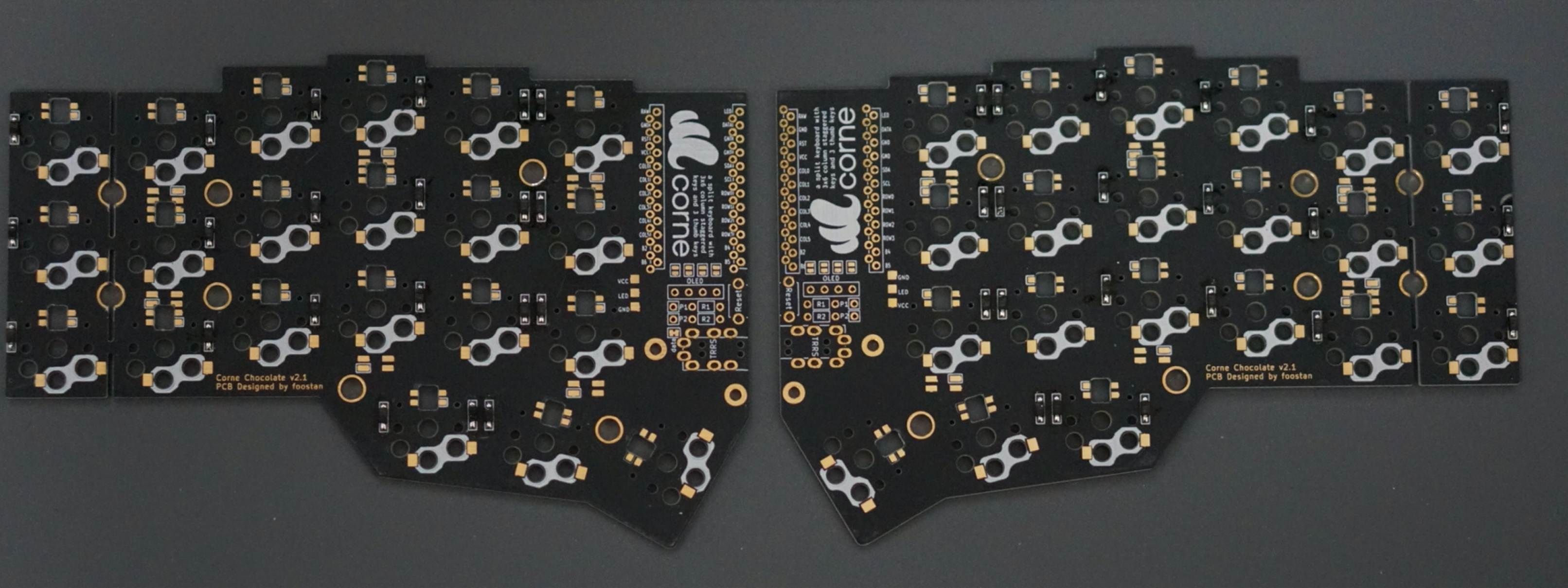

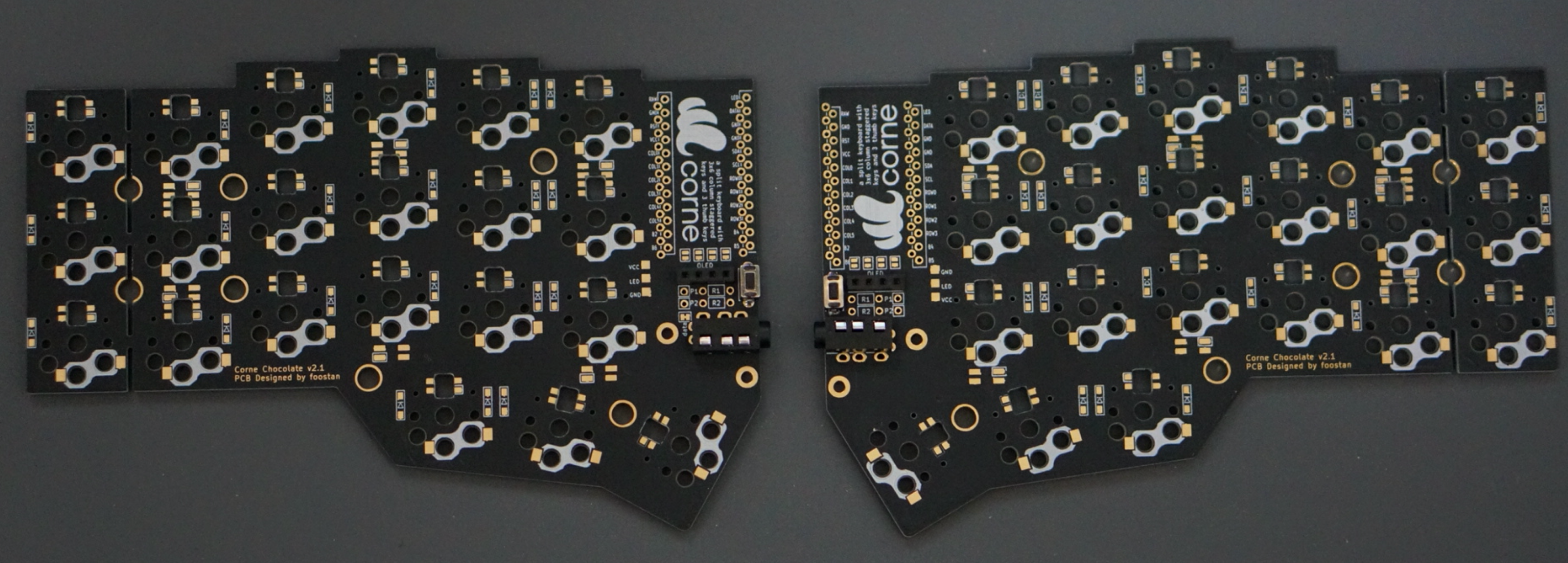

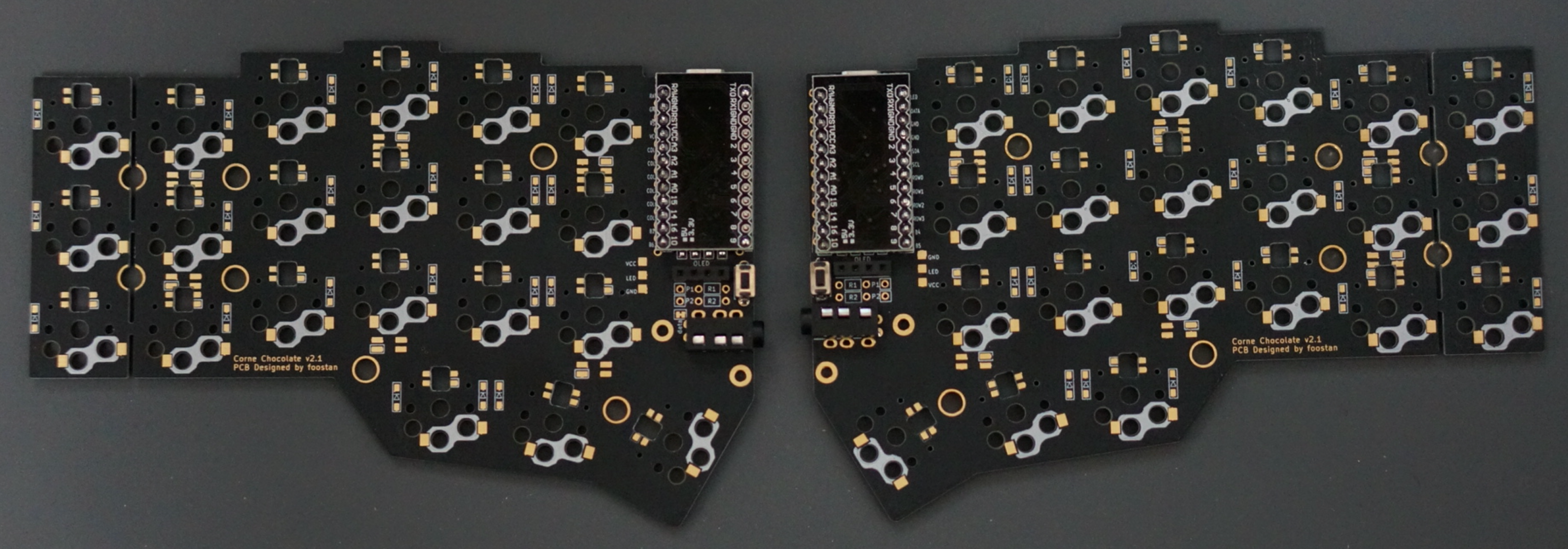

| PCB | 2 pieces | |

|

|

|

|

|

| Top plate | 2 pieces | |

|

|

|

|

|

| Bottom plate | Two pieces | PCB type and acrylic type are available |

|

2020-07-07 09:57:59 +02:00

|

|

|

| Pro Micro protection plate | 2 pieces | |

|

|

|

|

|

| Pro Micro | 2 | |

|

2019-12-27 18:44:33 +01:00

|

|

|

| TRRS Jack | 2 | |

|

2020-07-07 09:57:59 +02:00

|

|

|

| Tactile switch | 2 pieces | |

|

2019-12-27 18:44:33 +01:00

|

|

|

| Diode | 42 pieces | Compatible with chip components only

|

|

|

|

|

| Kailh PCB Socket (for Choc) | 42 | |

|

2020-07-07 09:57:59 +02:00

|

|

|

| Key switch | 42 pieces | Compatible with Choc (low profile) only |

|

|

|

|

|

| Key-caps | 42 | 1u 40, 1.5u 2 |

|

2019-12-27 18:44:33 +01:00

|

|

|

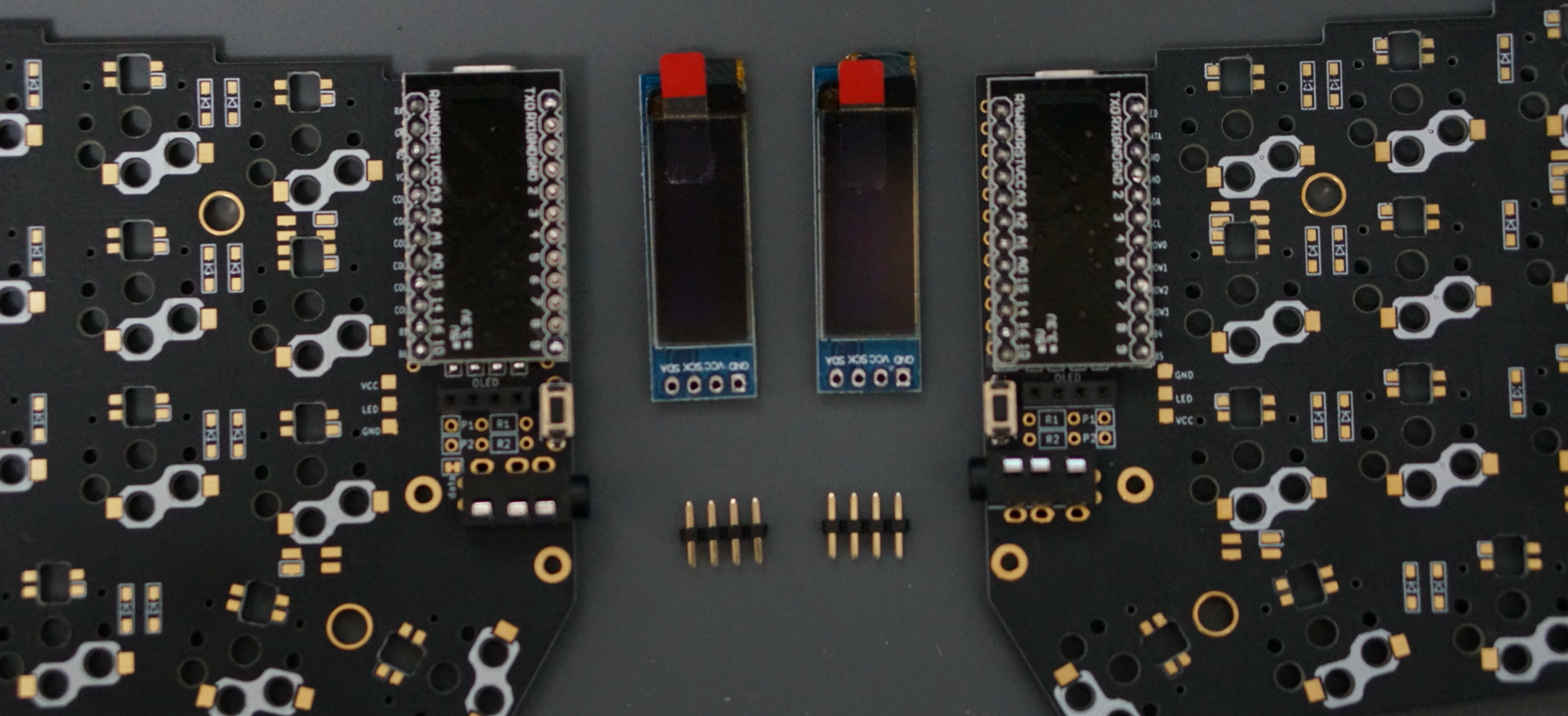

| OLED module | 2 pieces | |

|

|

|

|

|

| 4 pin headers | 2 | |

|

|

|

|

|

| 4 pin sockets | 2 | |

|

2020-12-01 00:41:17 +01:00

|

|

|

| Spacer M2 4.5mm | 10 | |

|

|

|

|

|

| Spacer M2 9mm | Four | |

|

|

|

|

|

| Screw M2 4mm | 28 | |

|

2019-12-27 18:44:33 +01:00

|

|

|

| Cushion rubber | 8 pieces | |

|

|

|

|

|

| TRS (3 pole) cable | 1 | TRRS (4 pole) cable also available |

|

|

|

|

|

| Micro USB Cable | 1 | |

|

|

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

### Optional

|

|

|

|

|

|

2021-05-15 08:51:41 +02:00

|

|

|

| Name | Count | Remarks |

|

2019-12-27 18:44:33 +01:00

|

|

|

|:-|:-|:-|

|

2020-07-07 09:57:59 +02:00

|

|

|

| SK6812MINI | 54 | 42 for backlight, 12 for under-glow |

|

|

|

|

|

|

2021-05-15 08:52:32 +02:00

|

|

|

## Advance preparation

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

If you build the firmware yourself,

|

|

|

|

|

it will take some time to set up the environment,

|

|

|

|

|

so it's best to start at the beginning. \

|

|

|

|

|

For more information,

|

|

|

|

|

please see <https://github.com/foostan/crkbd/blob/master/doc/firmware_en.md>.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

## Building

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

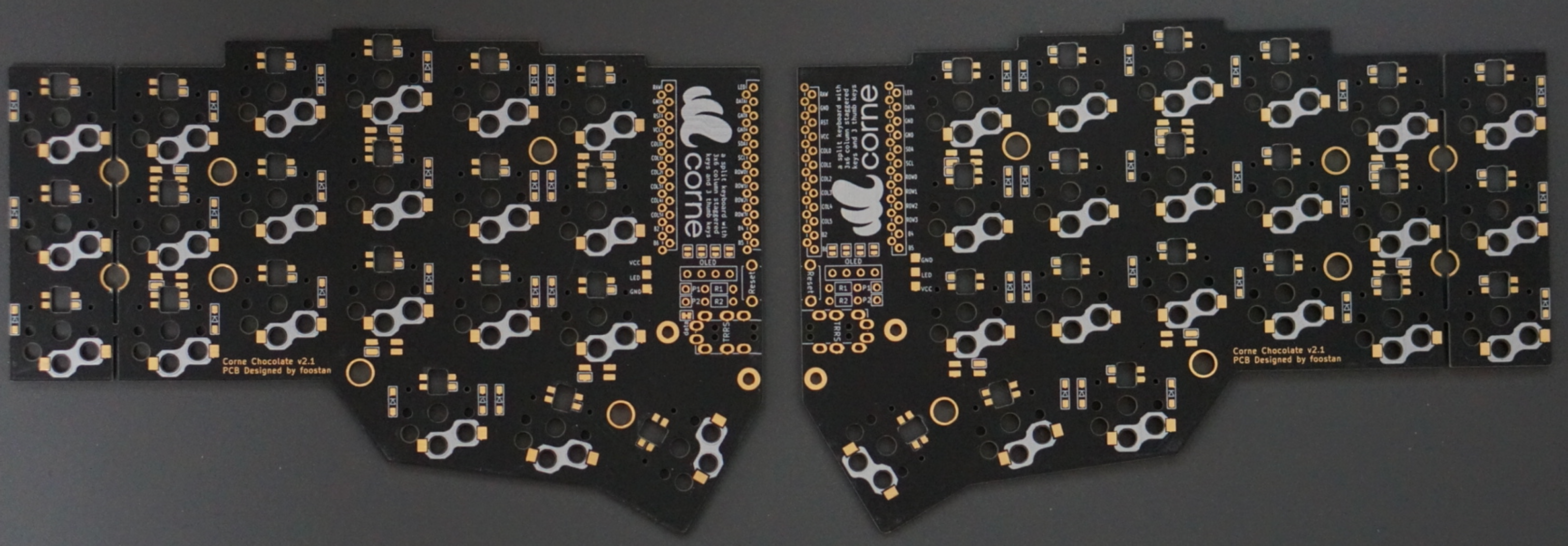

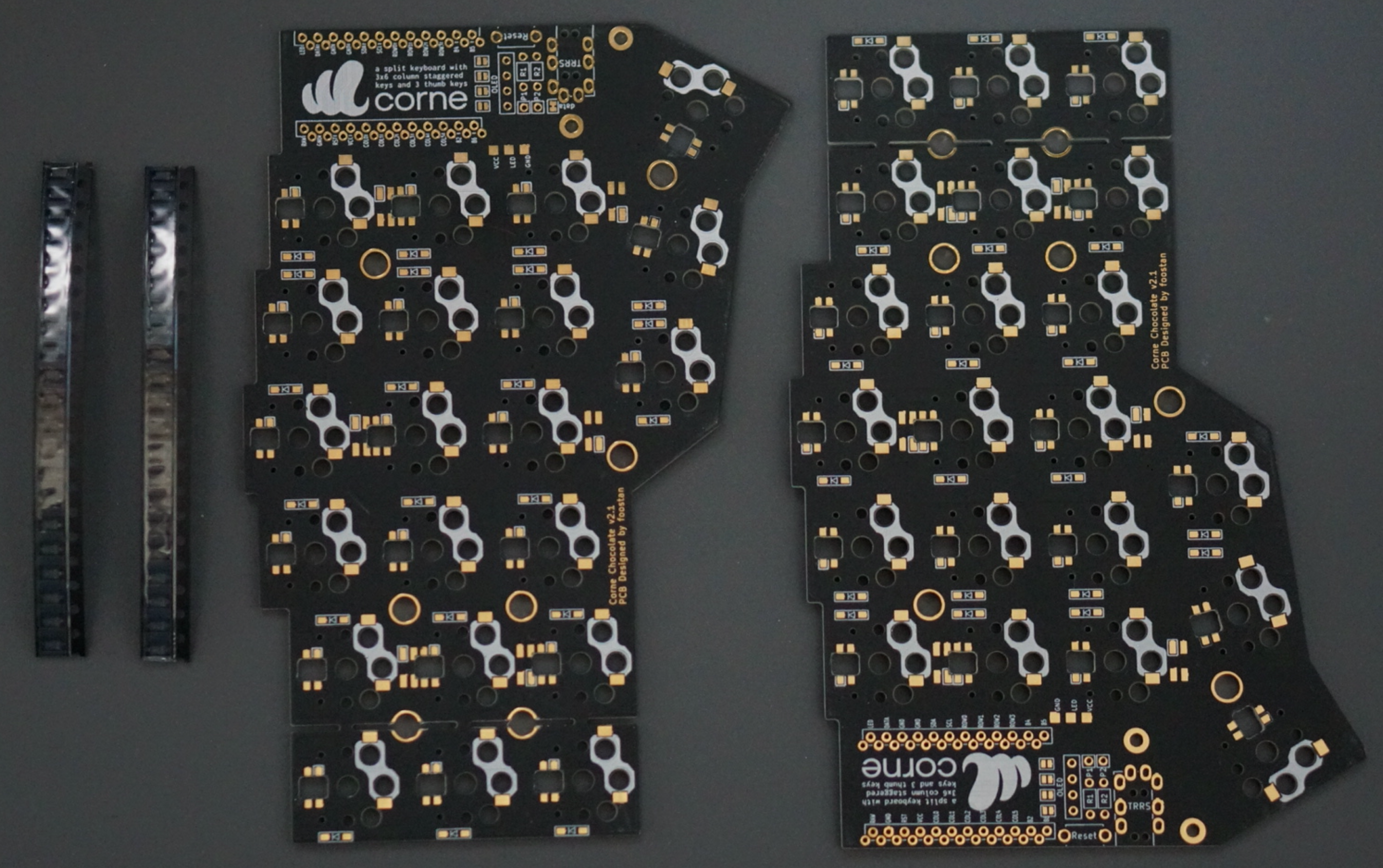

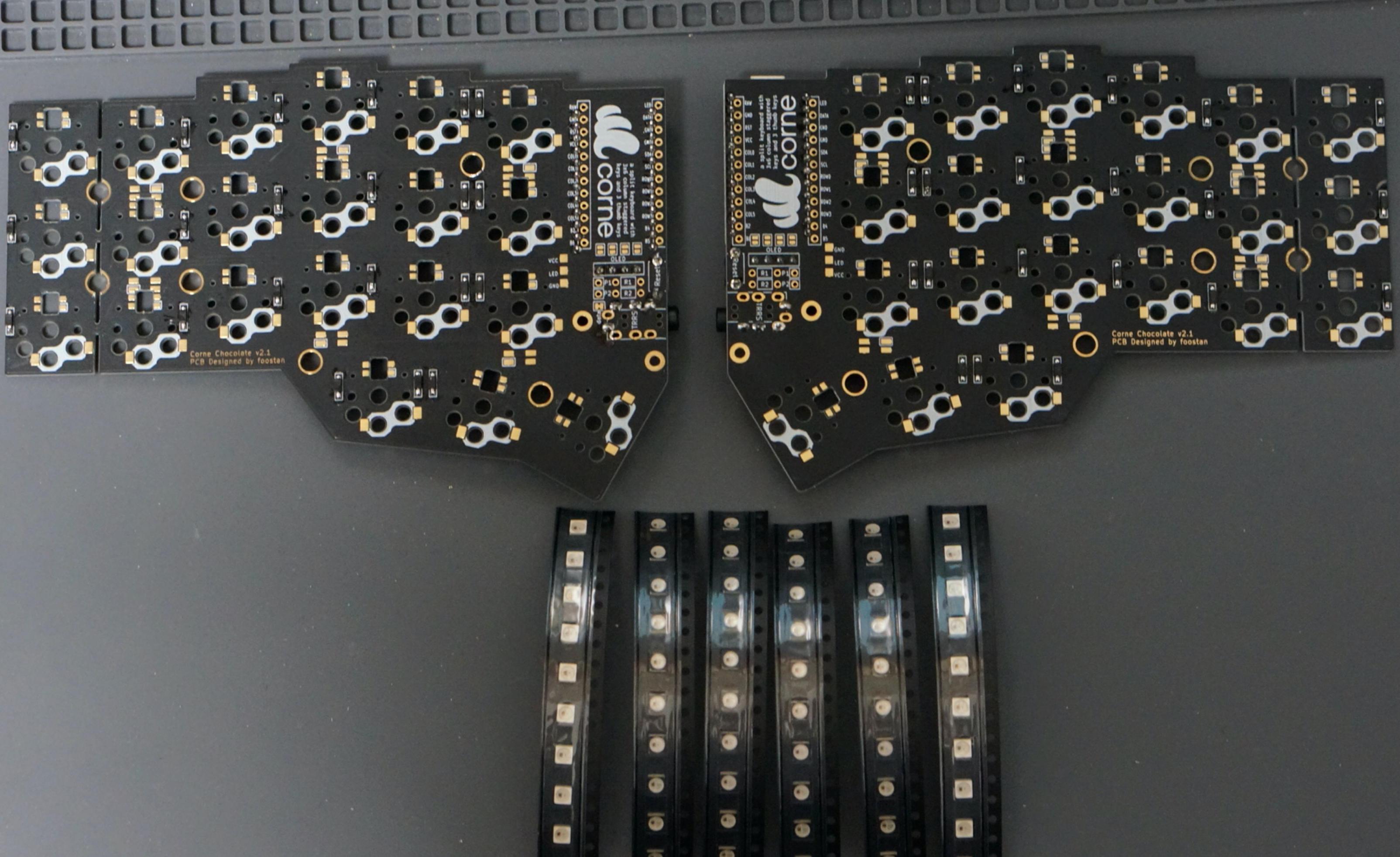

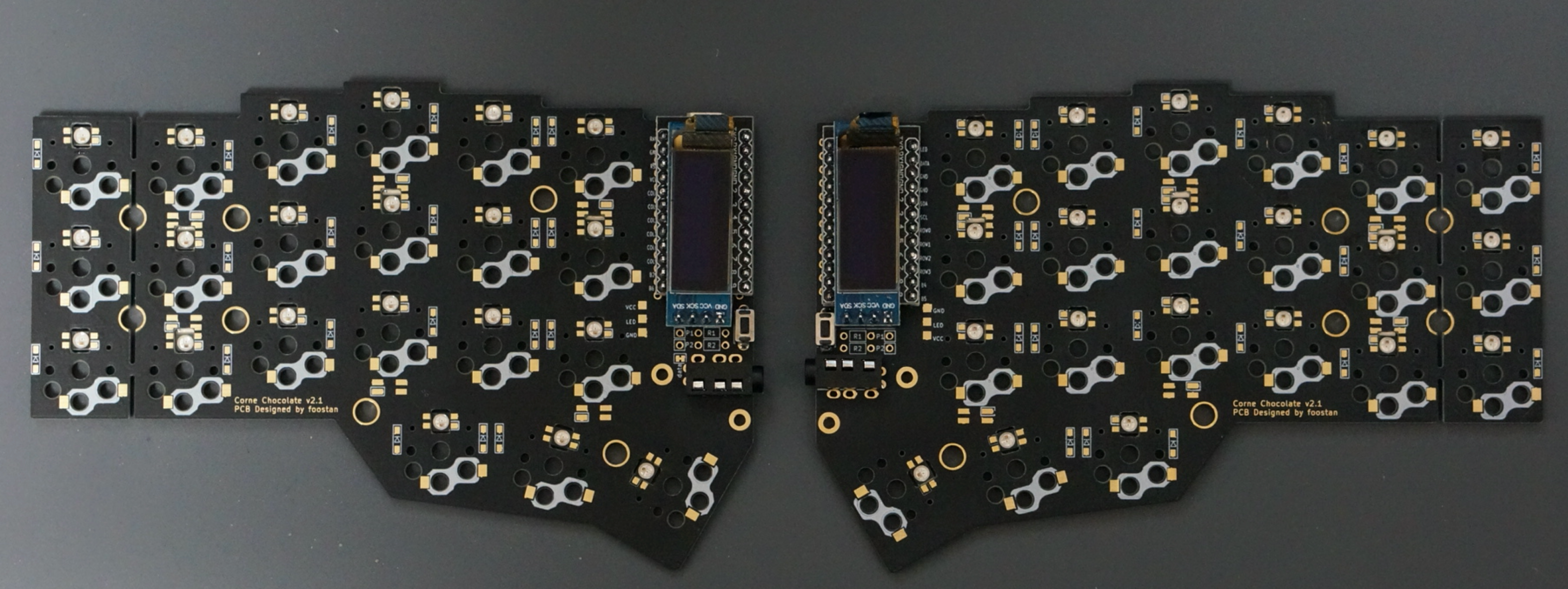

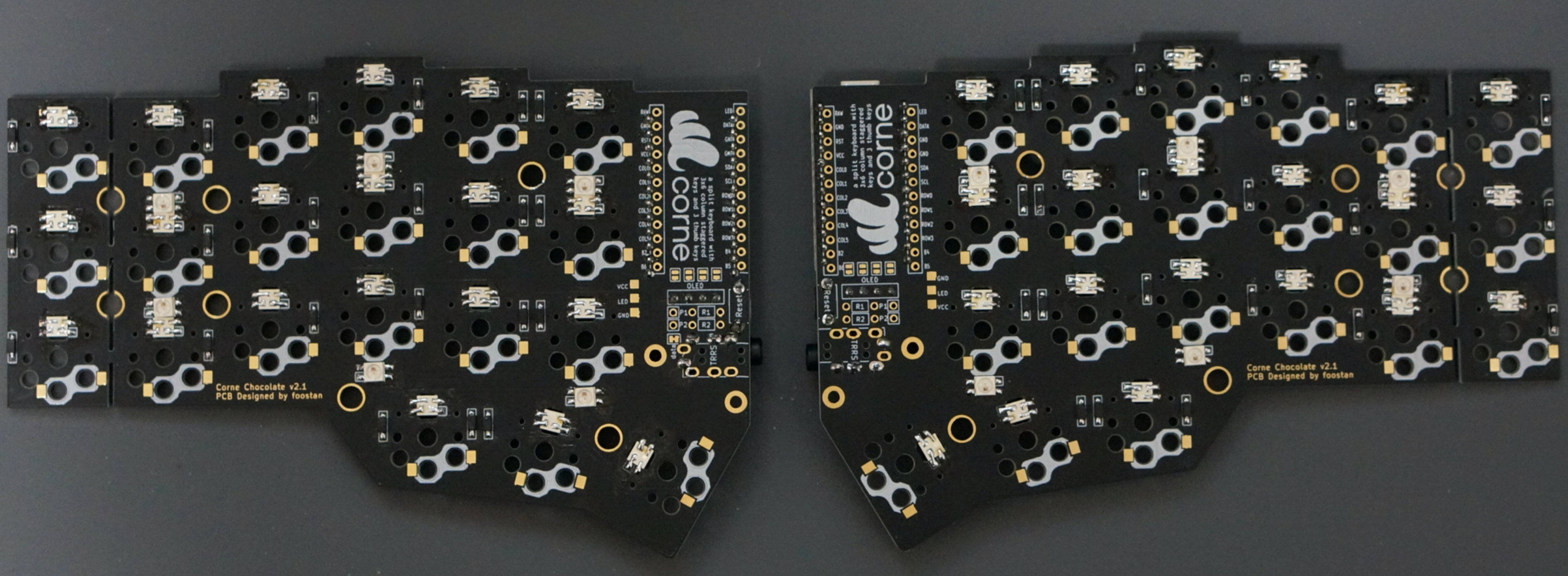

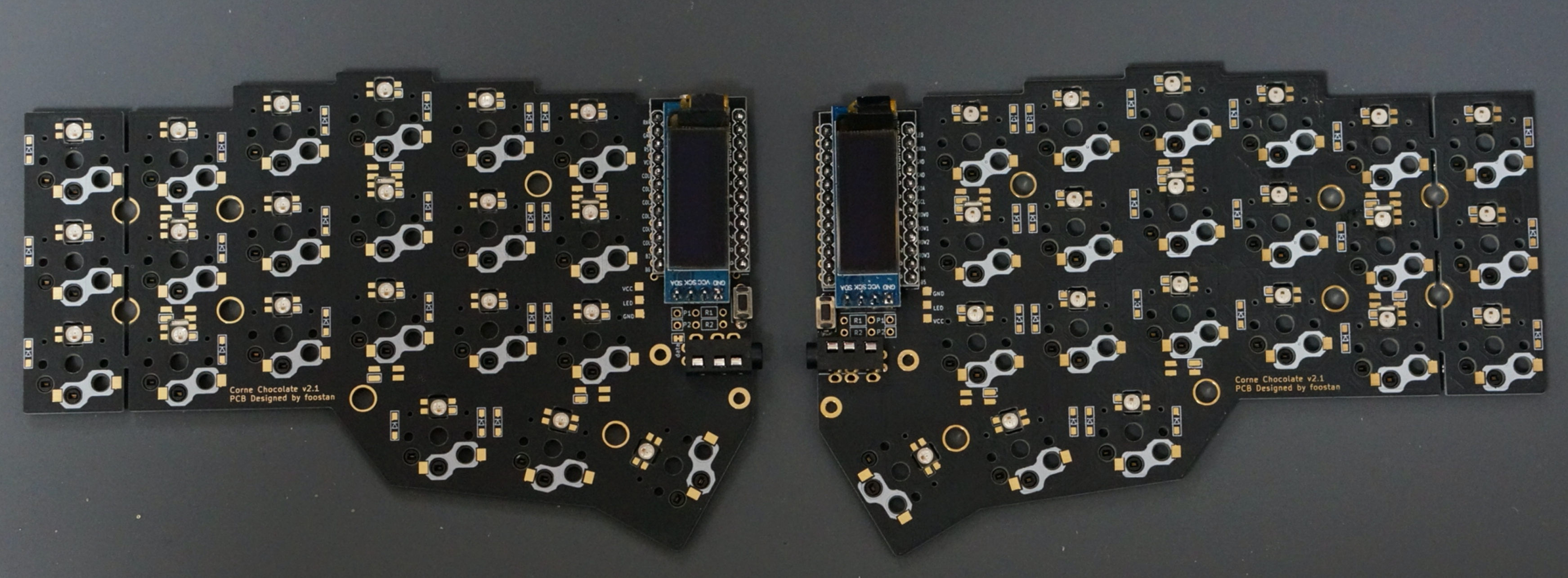

Since the PCB is reversible,

|

|

|

|

|

you first have to decide which one to use for the left side.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

### Diodes

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

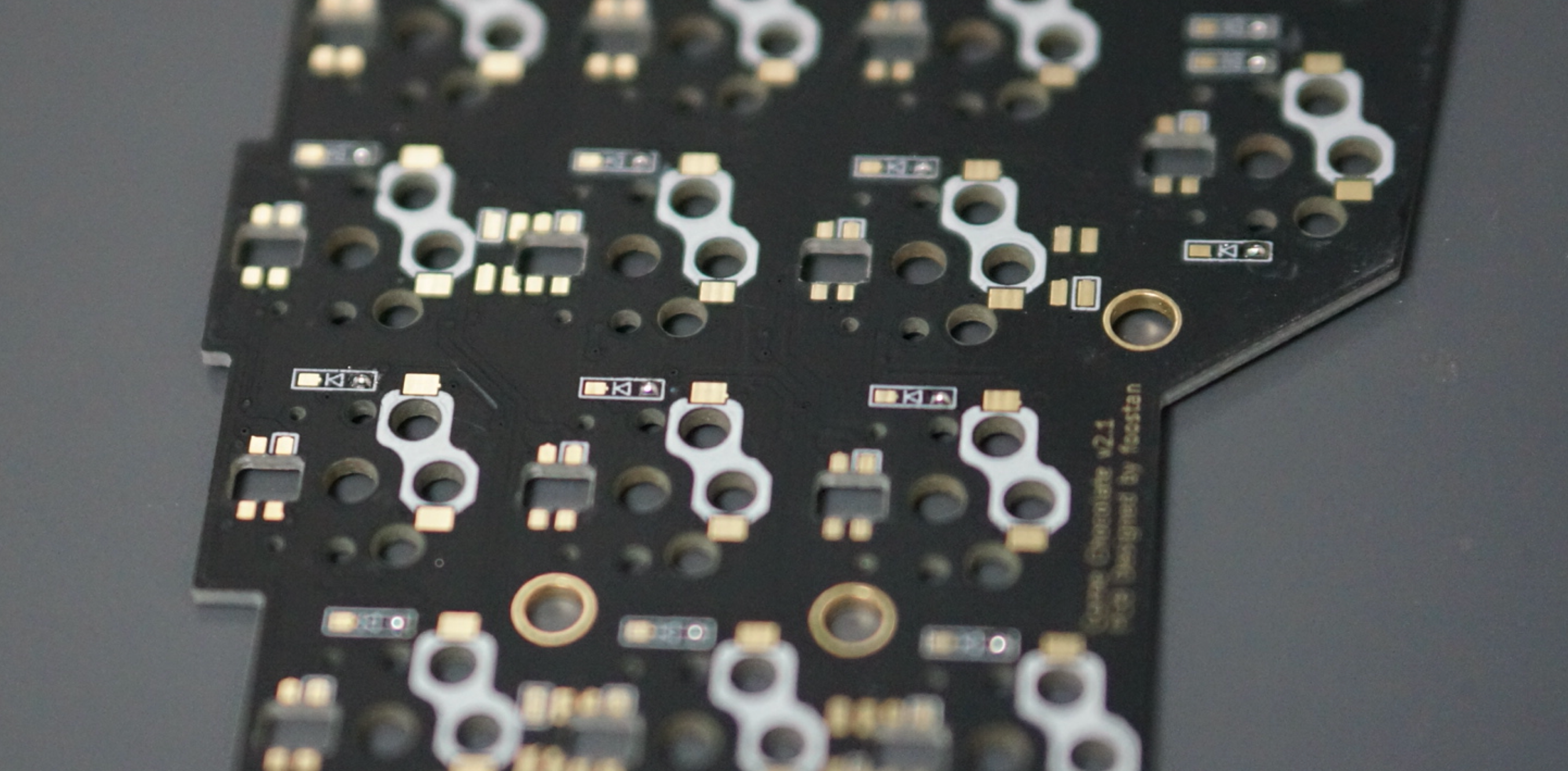

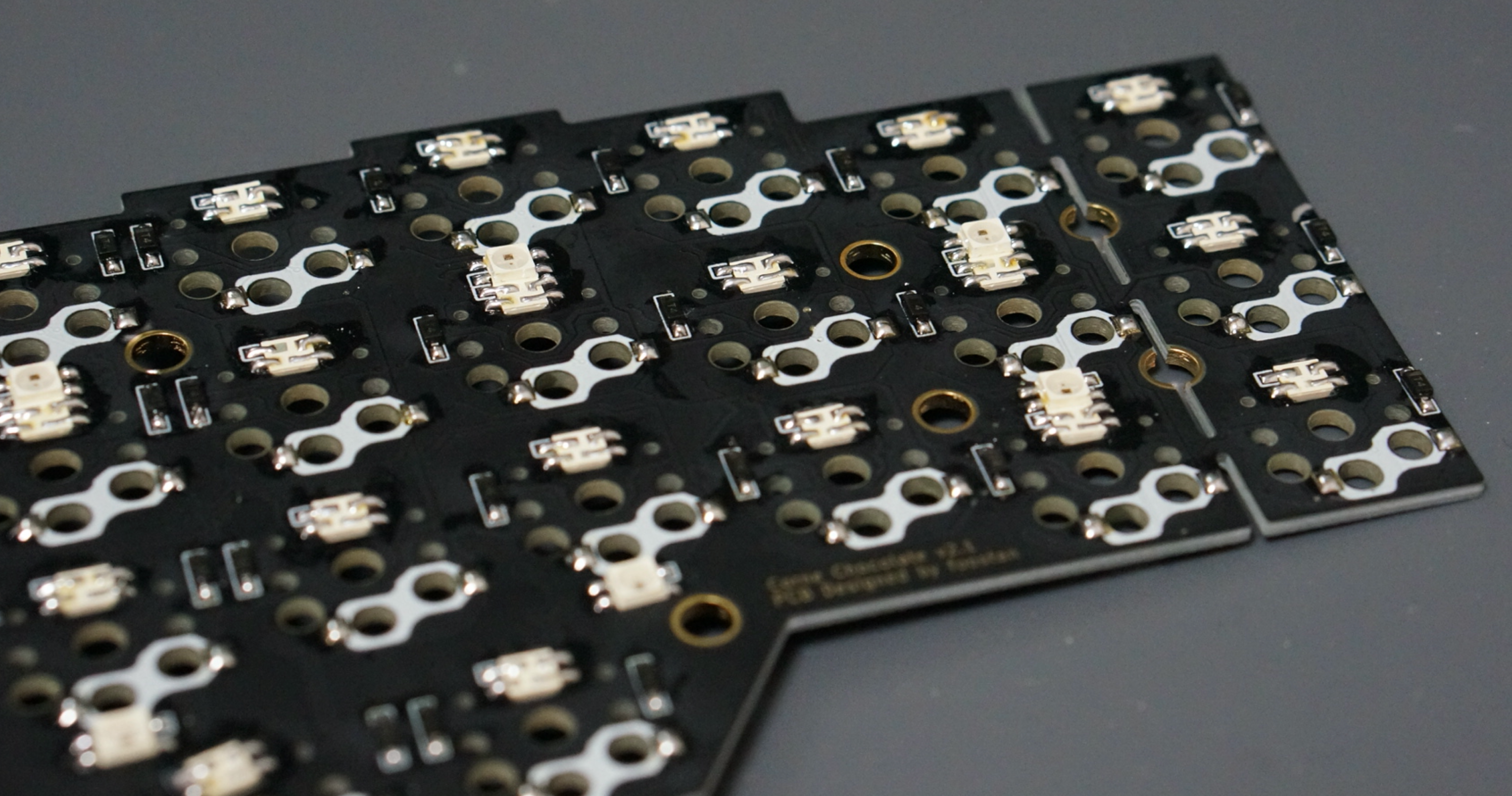

Solder the diodes to the PCB.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

On Corne Cherry, it is up to you to choose which side to attach,

|

|

|

|

|

but with Corne Chocolate you must **be sure to attach it to the back**.

|

|

|

|

|

Mounting on the front will interfere with the top plate.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

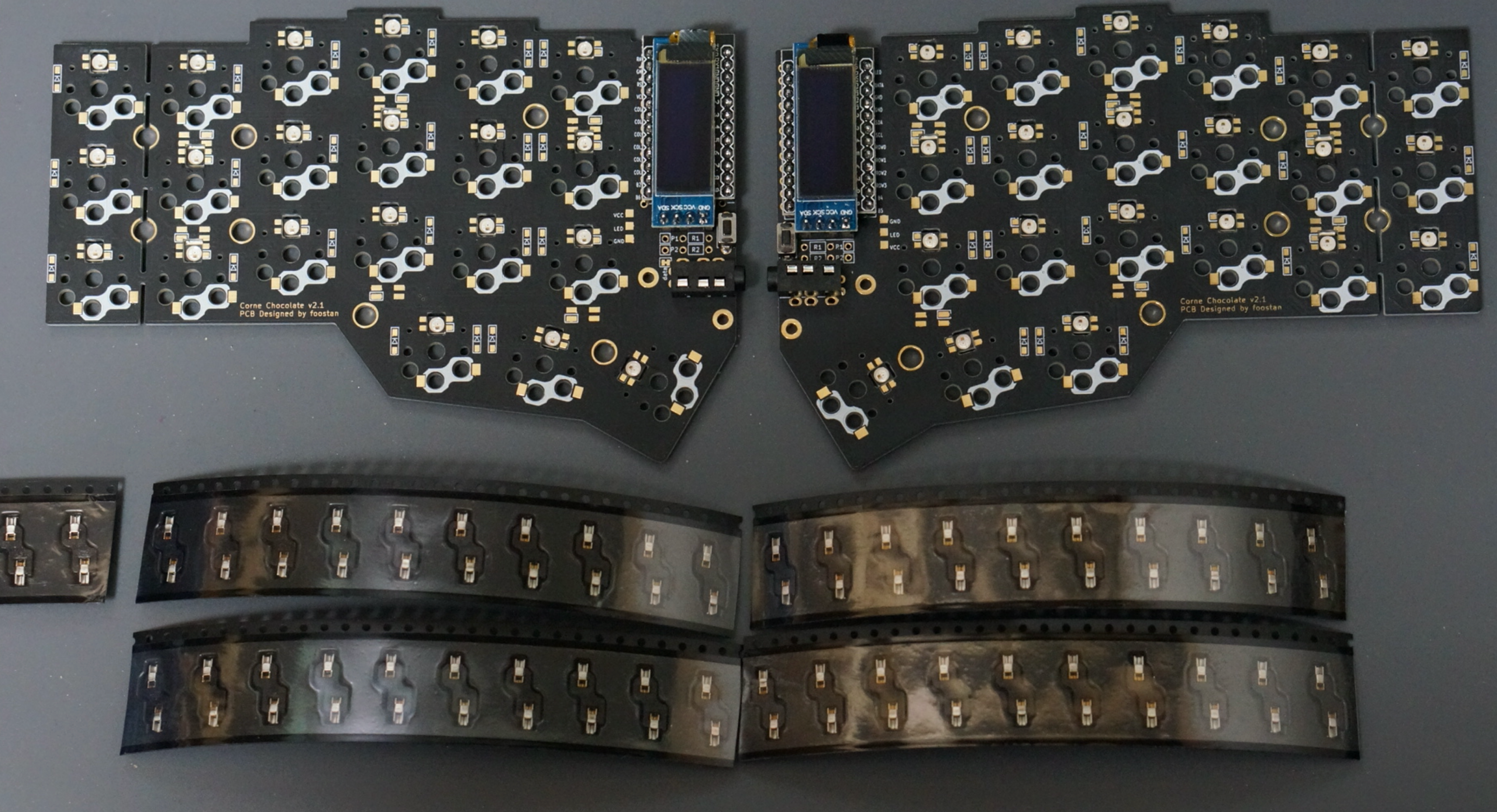

Since the diodes are very small,

|

|

|

|

|

it is easier to work with tweezers and inverted tweezers.

|

|

|

|

|

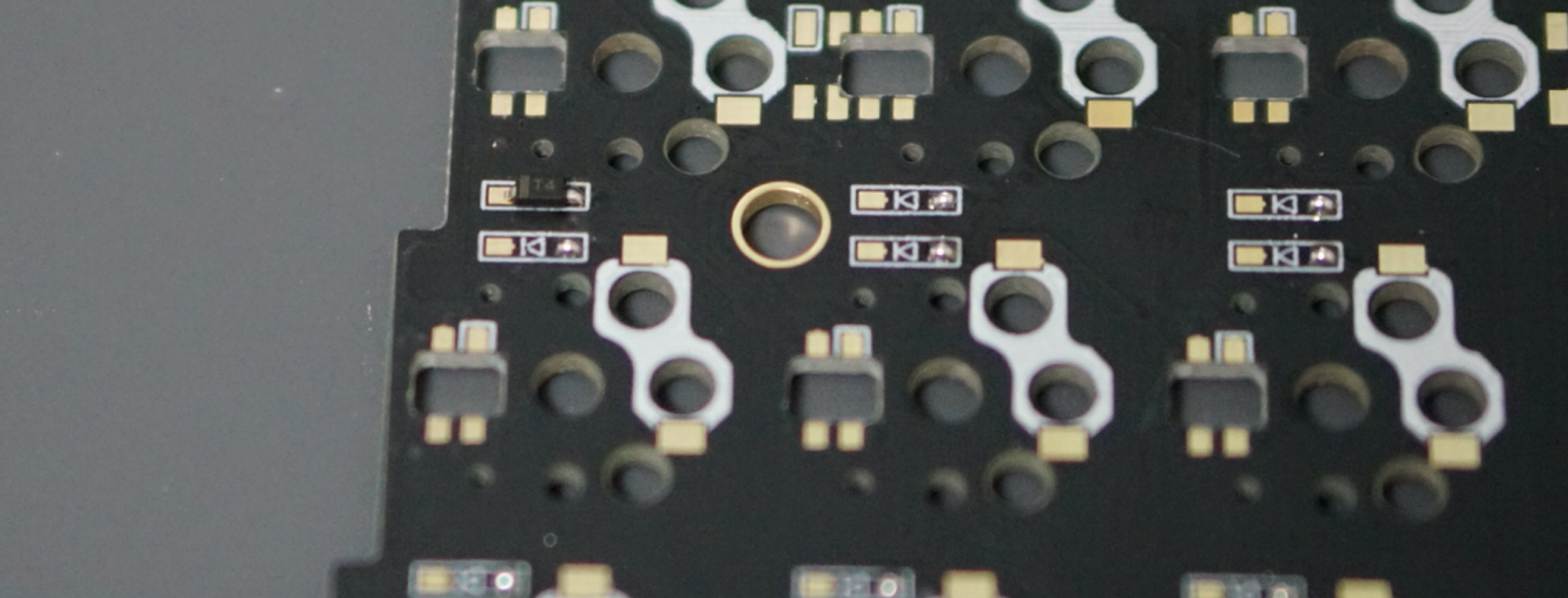

Since the **mounting orientation of the diode is crucial**,

|

2021-04-17 15:09:15 +02:00

|

|

|

it is possible to proceed smoothly

|

|

|

|

|

if you arrange the columns and rows to be mounted in advance,

|

2020-07-07 09:57:59 +02:00

|

|

|

as shown in the following photo.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

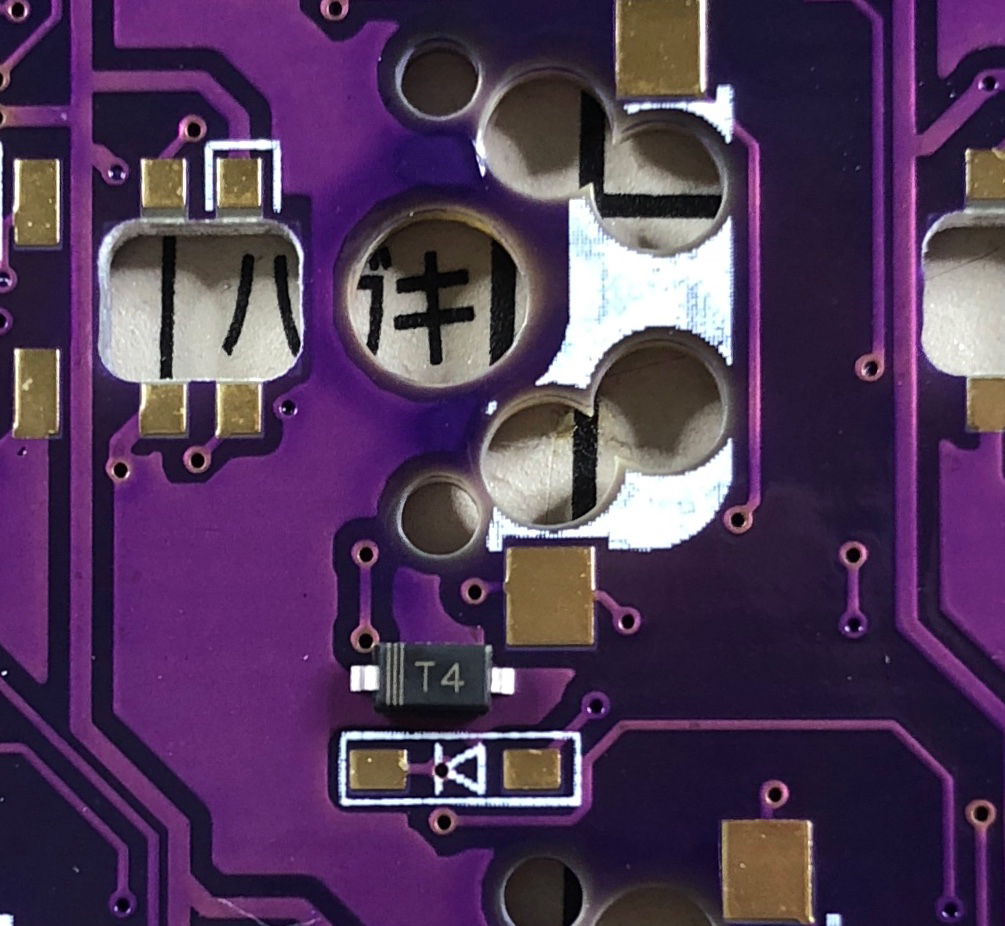

The orientation of the diode is as follows.

|

2021-04-17 15:09:15 +02:00

|

|

|

Attach the chip component so that the "|||" mark on the diode is facing the "|"

|

|

|

|

|

of the diode mark "|◁" on the PCB (image from Corne Cherry).

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

Tip for soldering on SMD parts:

|

|

|

|

|

First put solder only on the right side of the pad.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

Next, solder one of the diodes by melting the solder you already put on the board.

|

|

|

|

|

At this time,

|

2021-05-15 11:20:11 +02:00

|

|

|

it is recommended to use [reverse-action tweezers](https://www.alimed.com/_resources/cache/images/product/70895A_850x480-pad.jpg),

|

2021-04-17 15:09:15 +02:00

|

|

|

so that you can hold the SMD part firmly without applying force,

|

2020-07-07 09:57:59 +02:00

|

|

|

and concentrate on alignment and soldering instead.

|

|

|

|

|

Also, if the soldering iron is too hot or the solder is touched too long,

|

2021-05-15 11:20:11 +02:00

|

|

|

the flux contained in the solder may evaporate and form an undesirable pile solder,

|

2020-07-07 09:57:59 +02:00

|

|

|

but since it can be repaired later,

|

2021-05-15 11:20:11 +02:00

|

|

|

so at this point you should only care about attaching parts.

|

2020-07-07 09:57:59 +02:00

|

|

|

It's okay.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

Then solder the other pin.

|

2021-05-15 11:20:11 +02:00

|

|

|

Be careful not to apply too much solder,

|

|

|

|

|

as a small amount is sufficient.

|

2020-07-07 09:57:59 +02:00

|

|

|

If you have applied too much,

|

2021-05-15 11:20:11 +02:00

|

|

|

you can remove it with a suction pump, blotting wire

|

|

|

|

|

or by scooping it with a soldering iron.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

If the amount of solder on the pre-soldering side is too small,

|

|

|

|

|

add more soldering,

|

|

|

|

|

and if it is pilled up,

|

|

|

|

|

apply flux from above and heat to clean.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

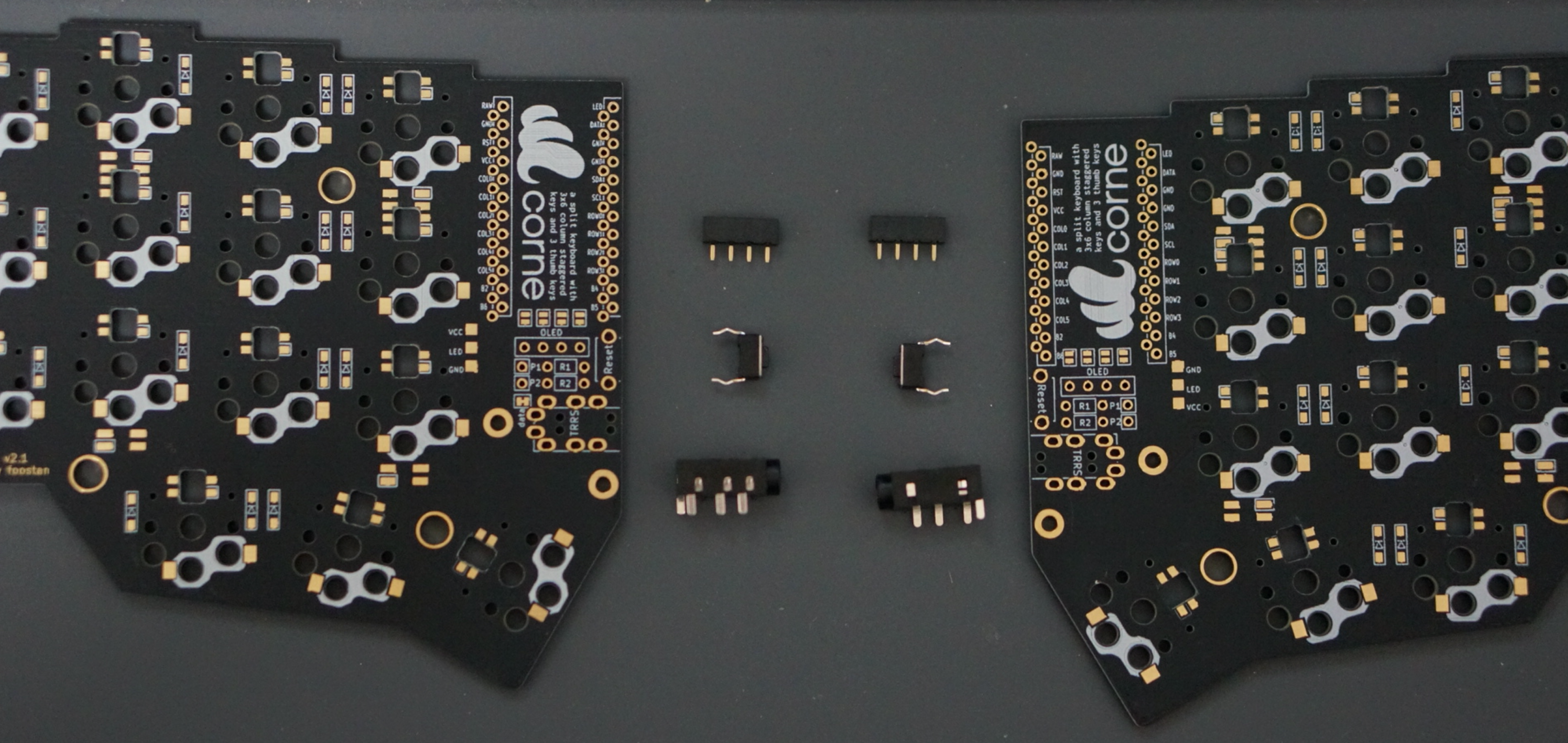

### TRRS jack, reset switch, pin socket

|

|

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

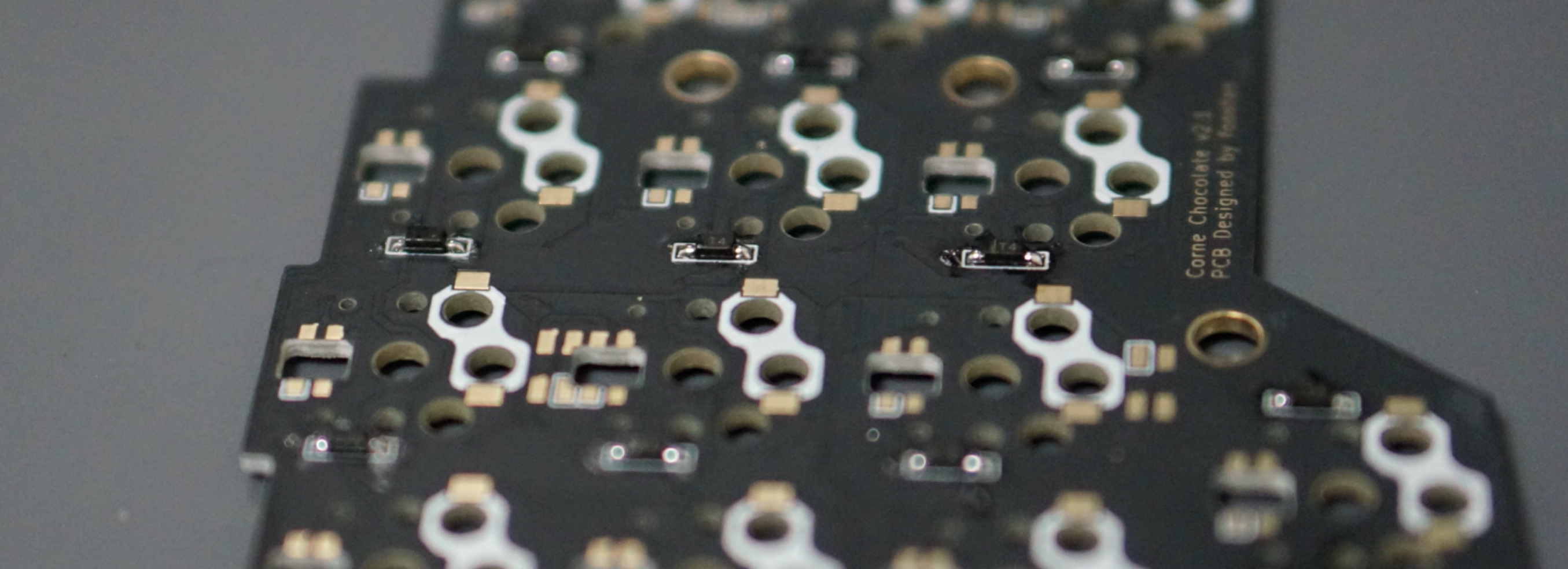

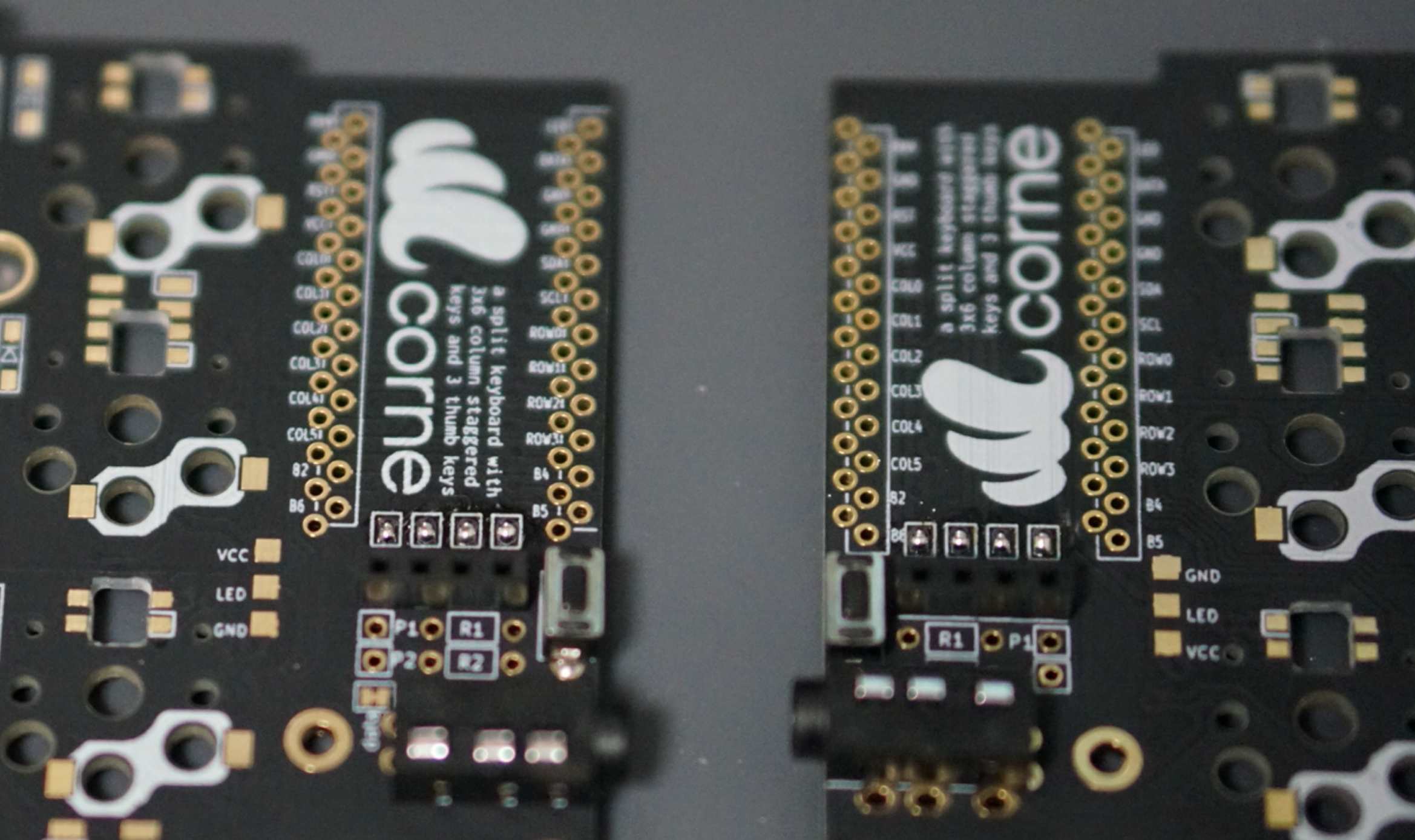

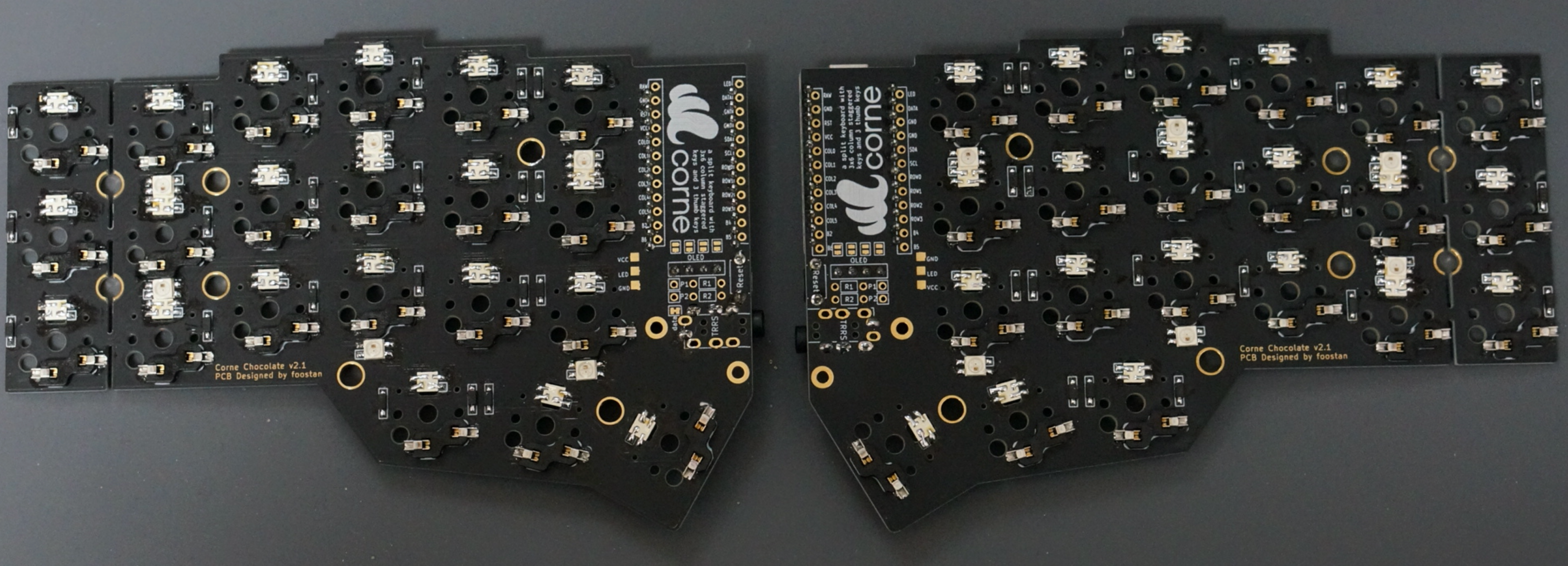

Solder the TRRS jack, reset switch and pin socket to the **front of the PCB**

|

|

|

|

|

as shown in the picture below.

|

|

|

|

|

Since the diode is attached on the back side,

|

|

|

|

|

it will be on the opposite side.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

### Jumpers for OLED modules

|

|

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

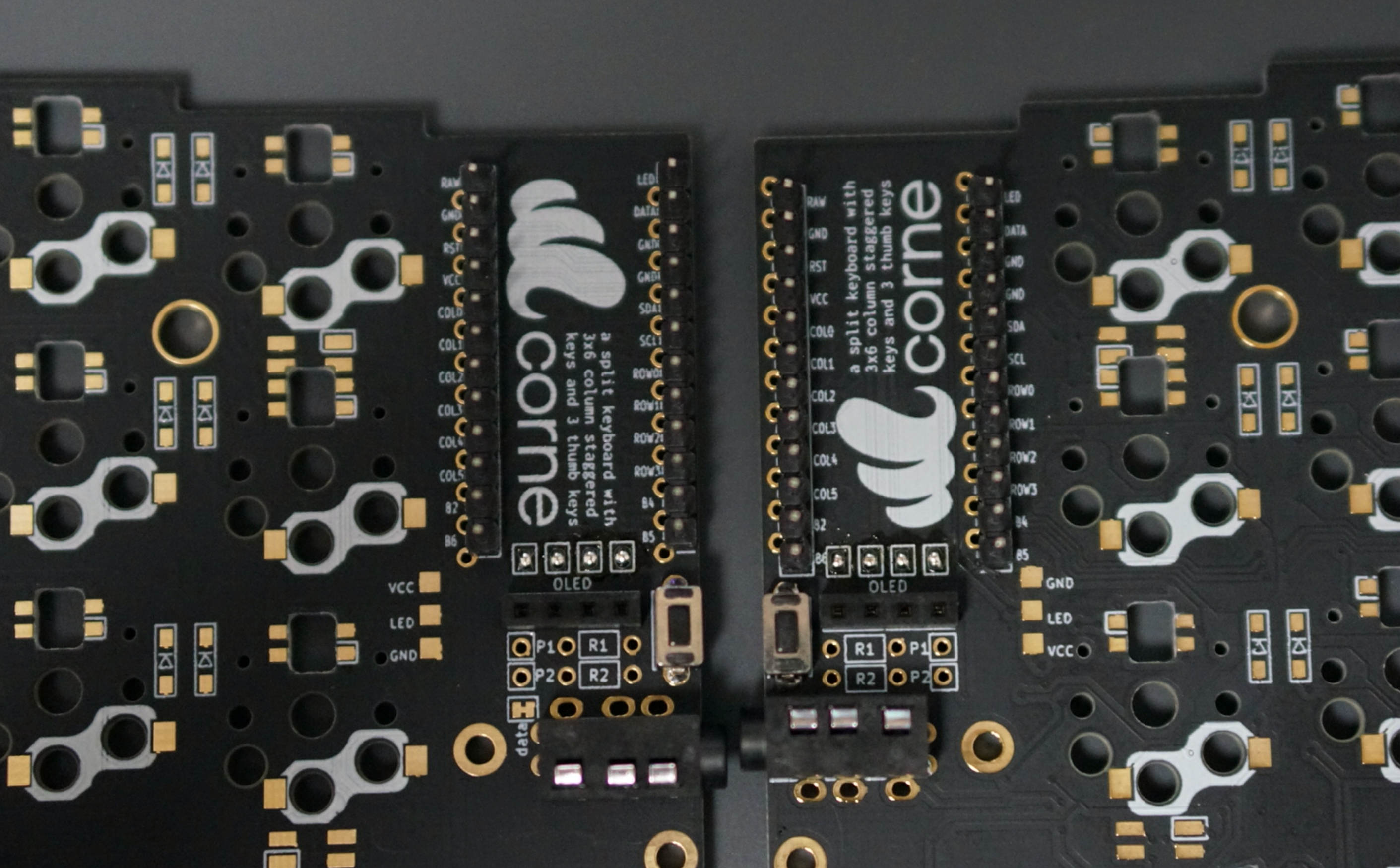

When using an OLED module, use solder as jumpers (4 times per side) as follows.

|

|

|

|

|

**Please jumper only on the surface**.

|

|

|

|

|

|

|

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

If the jumper doesn't work,

|

|

|

|

|

you probably have a small amount of solder,

|

|

|

|

|

or the flux has vaporized.

|

2021-04-29 22:59:31 +02:00

|

|

|

If so, you can fix the jumper by applying more solder or separate flux.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

### Pro Micro

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

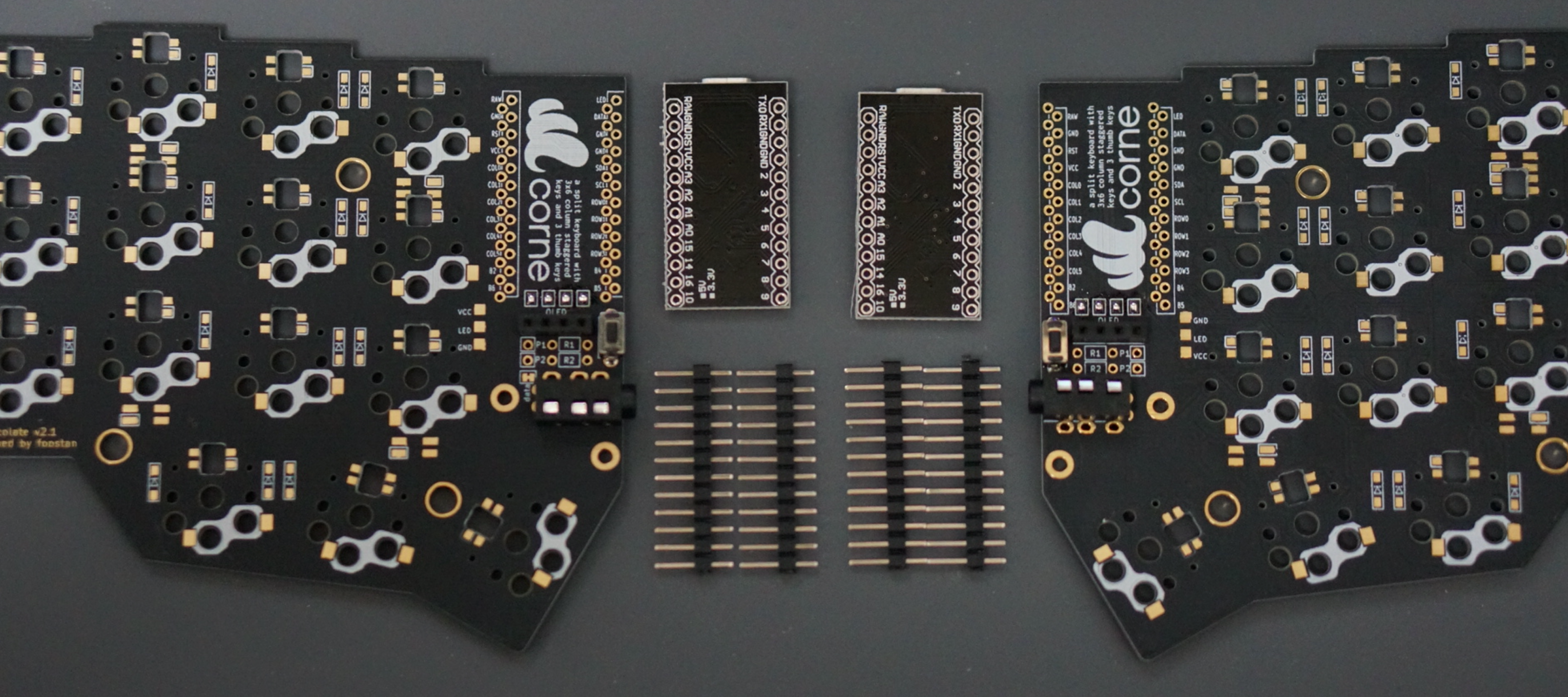

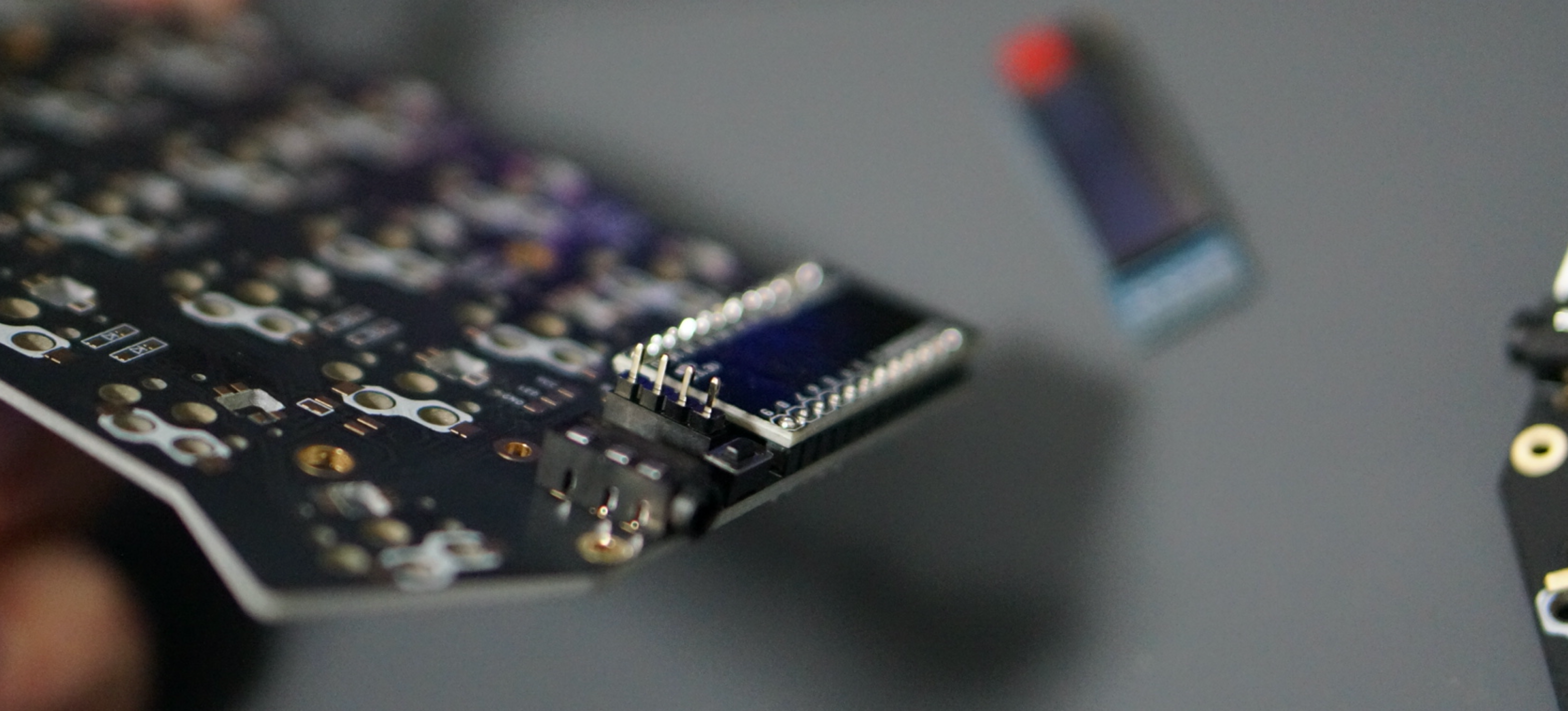

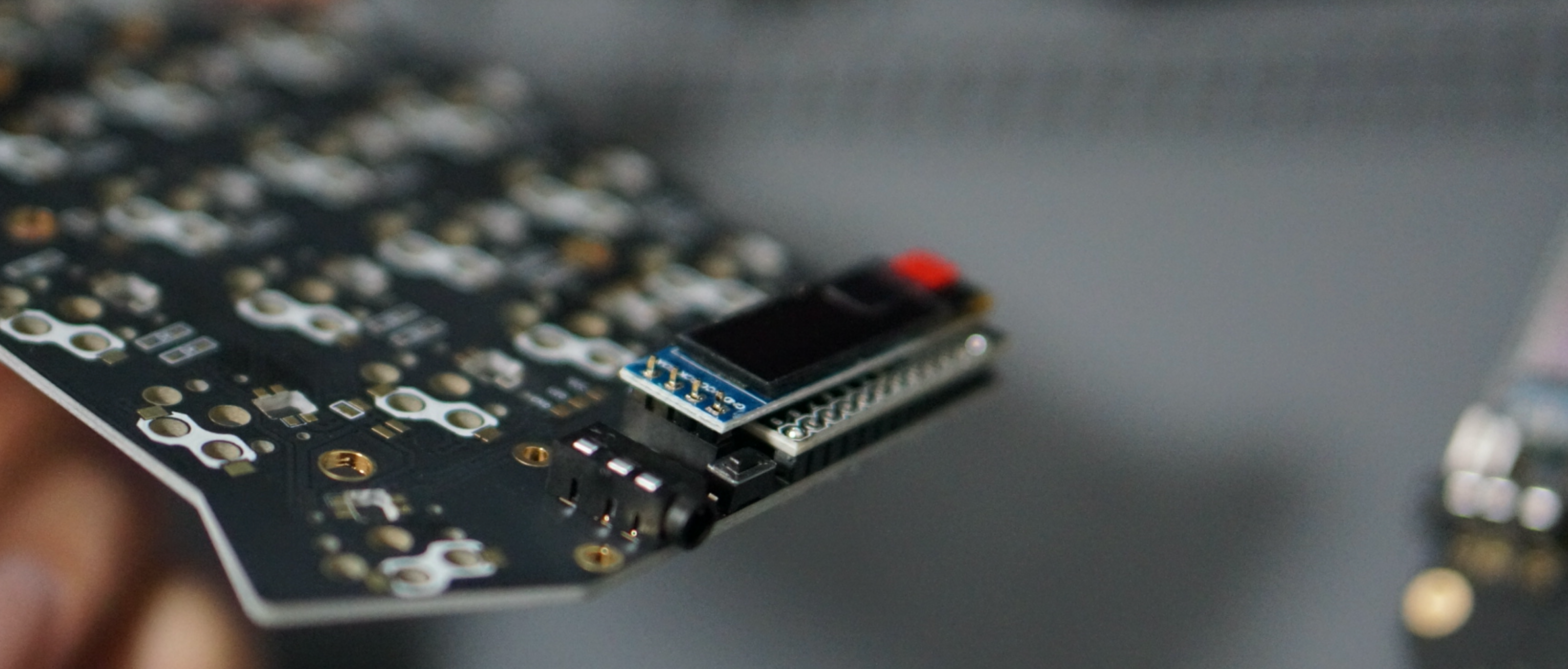

Solder the pin headers to the white frame

|

|

|

|

|

and solder the Pro Micro with back side up.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

|

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2021-05-15 11:20:11 +02:00

|

|

|

When using the spring-loaded pin headers,

|

|

|

|

|

please refer to the [Helix Build Guide](

|

|

|

|

|

https://github.com/MakotoKurauchi/helix/blob/master/Doc/buildguide_en.md#pro-micro).

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

### OLED module

|

|

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

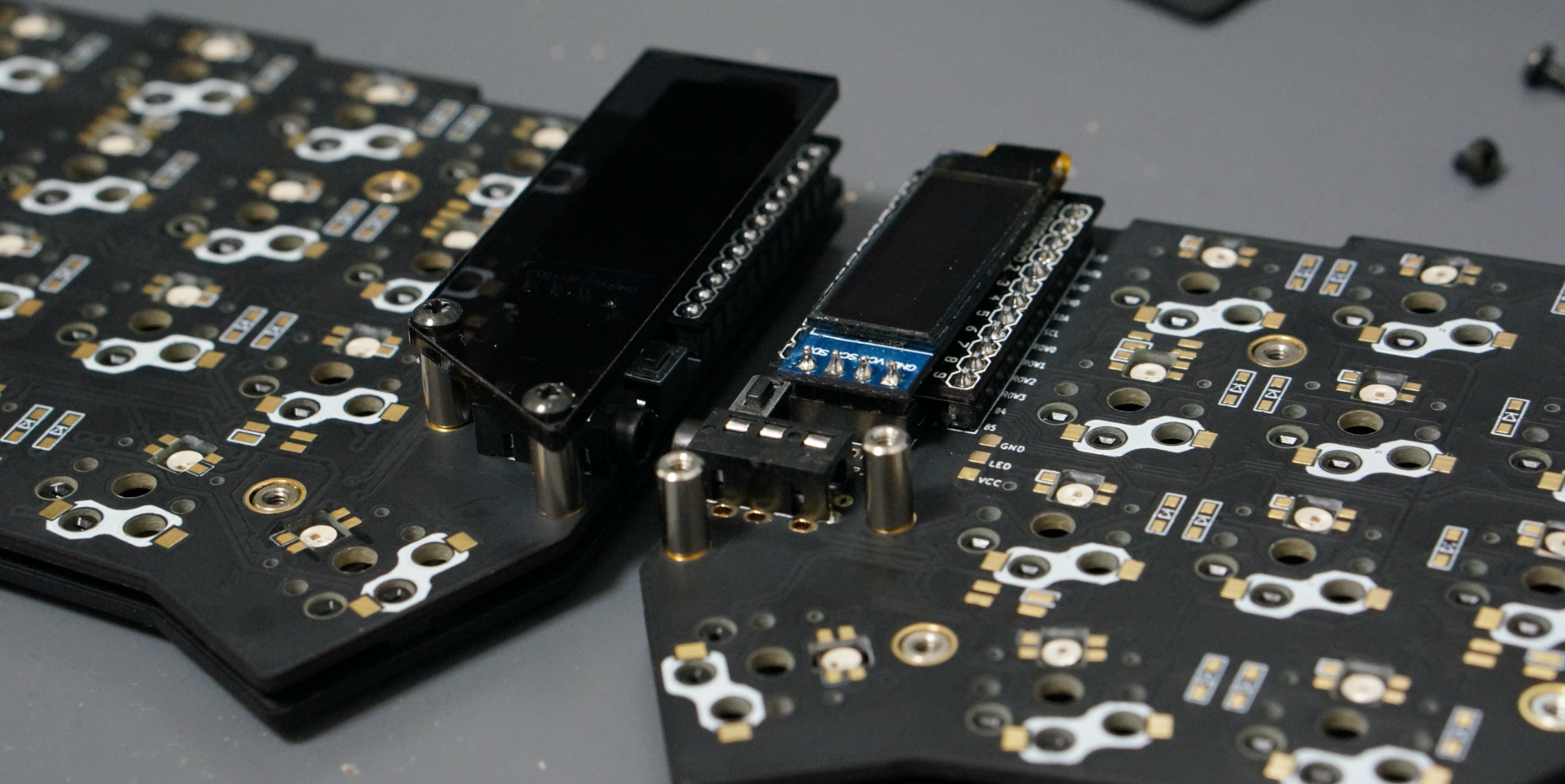

Insert the pin header into the OLED pin socket first,

|

|

|

|

|

then solder the pin header and the OLED module.

|

|

|

|

|

At this time,

|

2021-05-15 11:21:51 +02:00

|

|

|

make sure that the OLED module sits tightly on the socket

|

2021-04-17 15:09:15 +02:00

|

|

|

while holding it down with your finger,

|

2020-07-07 09:57:59 +02:00

|

|

|

because it tends to stick out easily.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

|

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

### Operation check

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

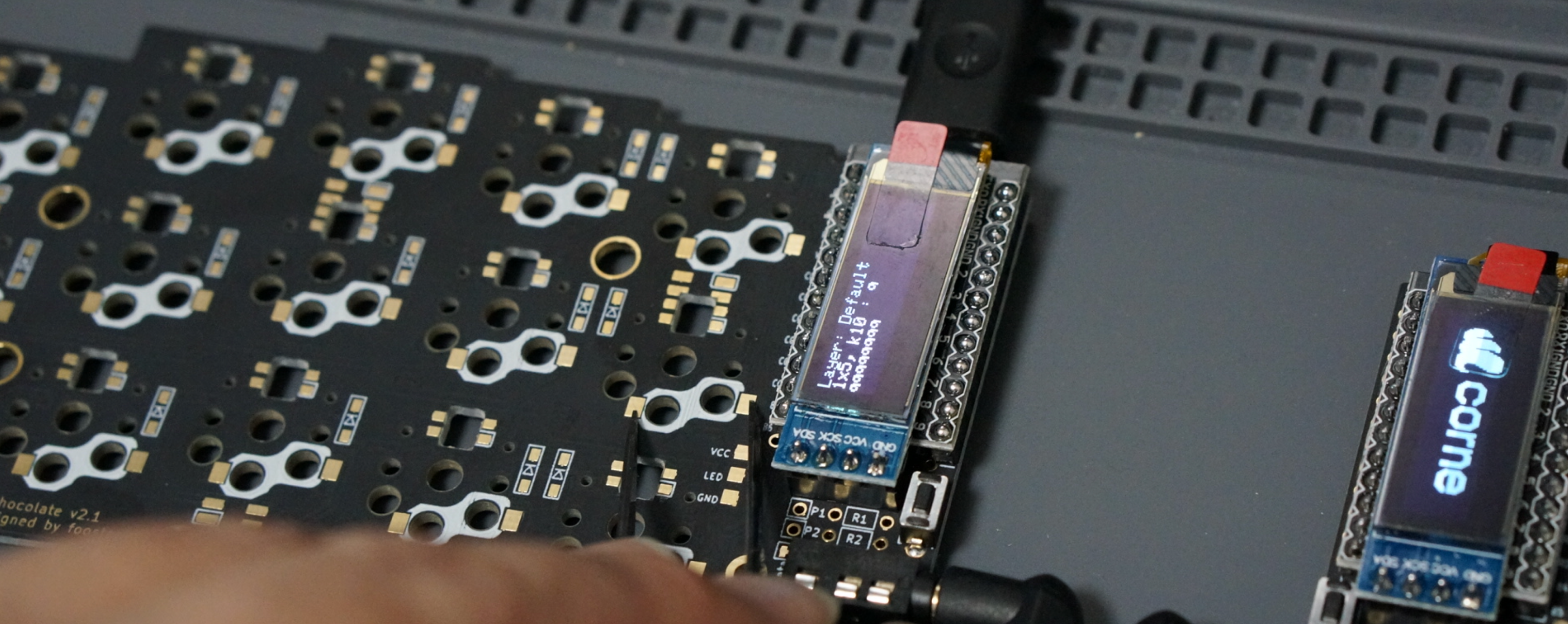

We recommend that you check the operation at the stage

|

|

|

|

|

where the Pro Micro and OLED modules are attached

|

|

|

|

|

(it is difficult to isolate the problem at the end).

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

Before checking the correct operation,

|

2021-04-17 15:09:15 +02:00

|

|

|

flash the crkbd firmware to the Pro Micro

|

|

|

|

|

by referring to the [Firmware](#firmware) section below

|

2020-07-07 09:57:59 +02:00

|

|

|

(be sure to insert it on both sides).

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

Operation confirmation is performed

|

|

|

|

|

by connecting the left hand side to a PC with Micro USB

|

2020-07-07 09:57:59 +02:00

|

|

|

and connecting the left hand side and the right hand side with a TRS cable.

|

|

|

|

|

Since there may be a defect such as a jack,

|

2021-04-17 15:09:15 +02:00

|

|

|

make sure to connect the left and right

|

|

|

|

|

instead of one by one before checking the operation.

|

2020-07-07 09:57:59 +02:00

|

|

|

If you have done this correctly,

|

|

|

|

|

short-circuit the pad to attach the PCB socket with tweezers,

|

|

|

|

|

and the key pressed on the OLED module will be displayed.

|

|

|

|

|

|

|

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

## LED (optional)

|

|

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

I will install SK6812MINI.

|

2020-07-07 09:57:59 +02:00

|

|

|

The LED can be mounted even after completion,

|

|

|

|

|

so if you are worried about mounting it,

|

|

|

|

|

we recommend that you skip this chapter and complete it first.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

SK6812MINI is very heat sensitive and breaks easily.

|

2021-04-17 15:09:15 +02:00

|

|

|

We recommend using a soldering iron with a temperature control function

|

|

|

|

|

and operating at a temperature of about 220°C to 270°C.

|

2020-07-07 09:57:59 +02:00

|

|

|

Even if the temperature is set that low,

|

|

|

|

|

the LED will be damaged if the iron is left on it for a long time,

|

|

|

|

|

so try to solder as quickly as possible.

|

|

|

|

|

Solder four LEDs at a time,

|

2021-04-17 15:09:15 +02:00

|

|

|

but we recommend soldering two at a time instead of four at a time

|

|

|

|

|

to prevent the LED temperature from rising,

|

2020-07-07 09:57:59 +02:00

|

|

|

as this will make it less likely to overheat.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

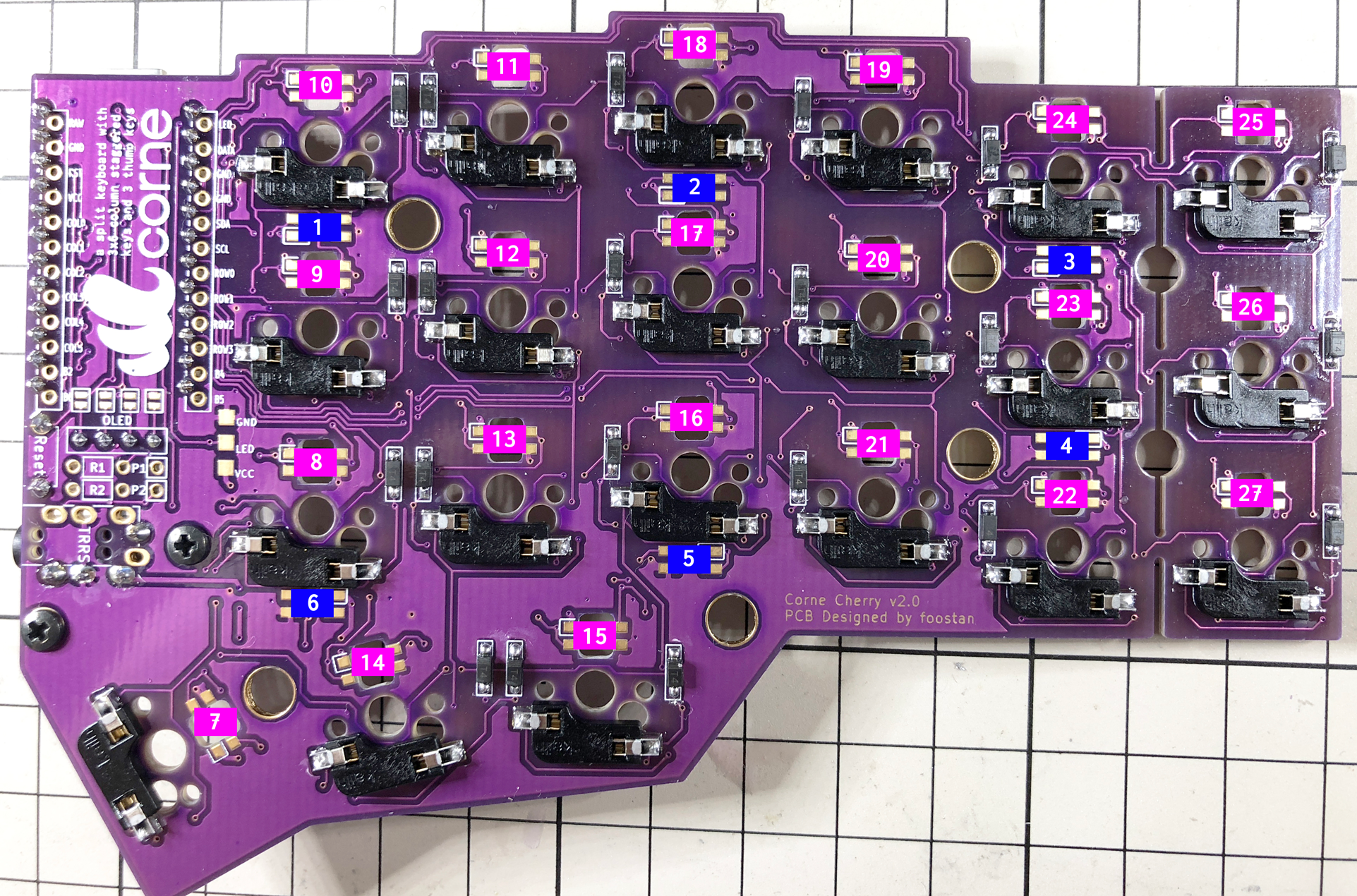

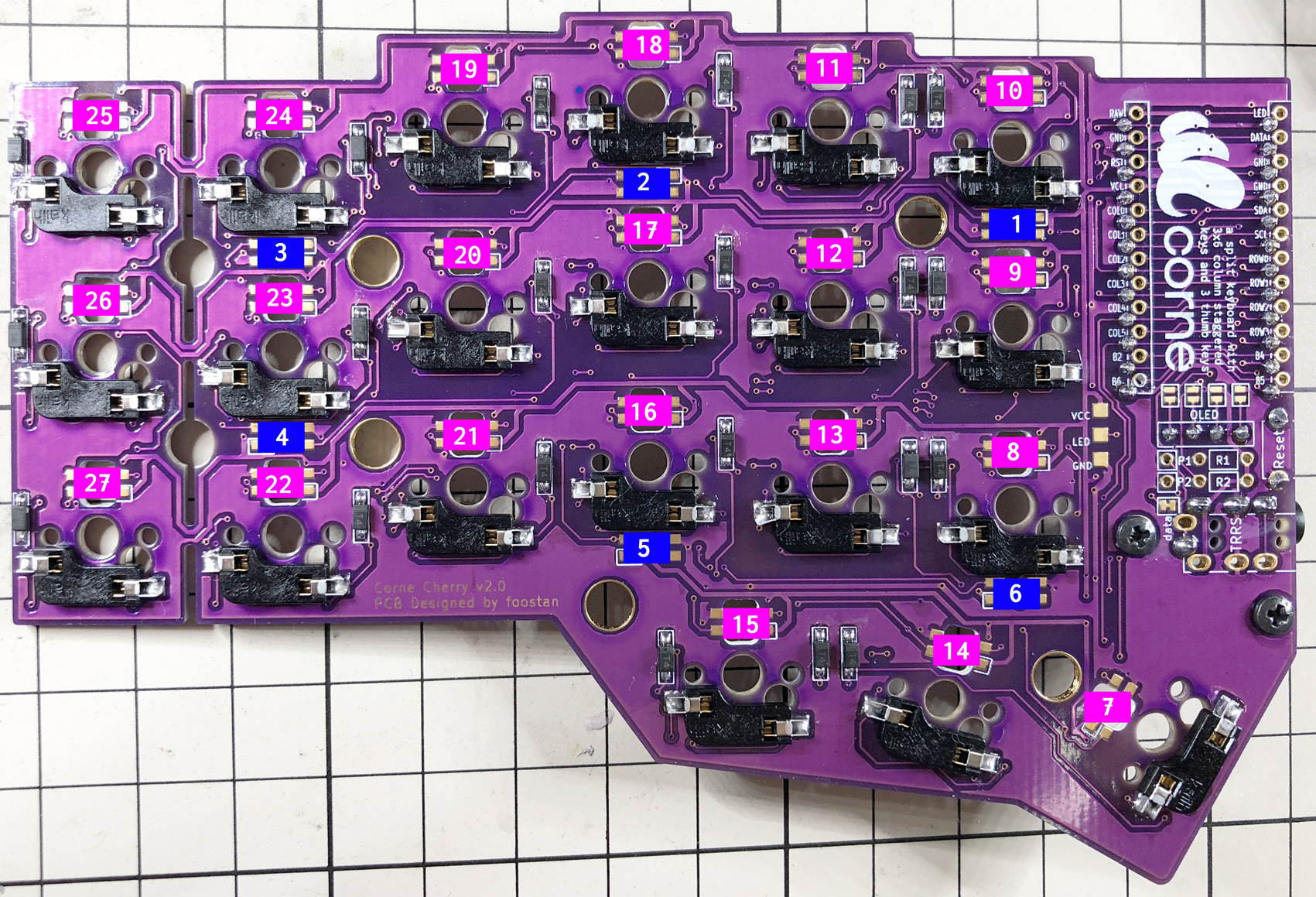

First, check the mounting position.

|

|

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

Solder 1 - 6 so that the back side (under-glow) shines,

|

|

|

|

|

7 - 27 so that the front side (back-light) shines.

|

|

|

|

|

Below is the location to attach the LED (image from Corne Cherry).

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

|

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

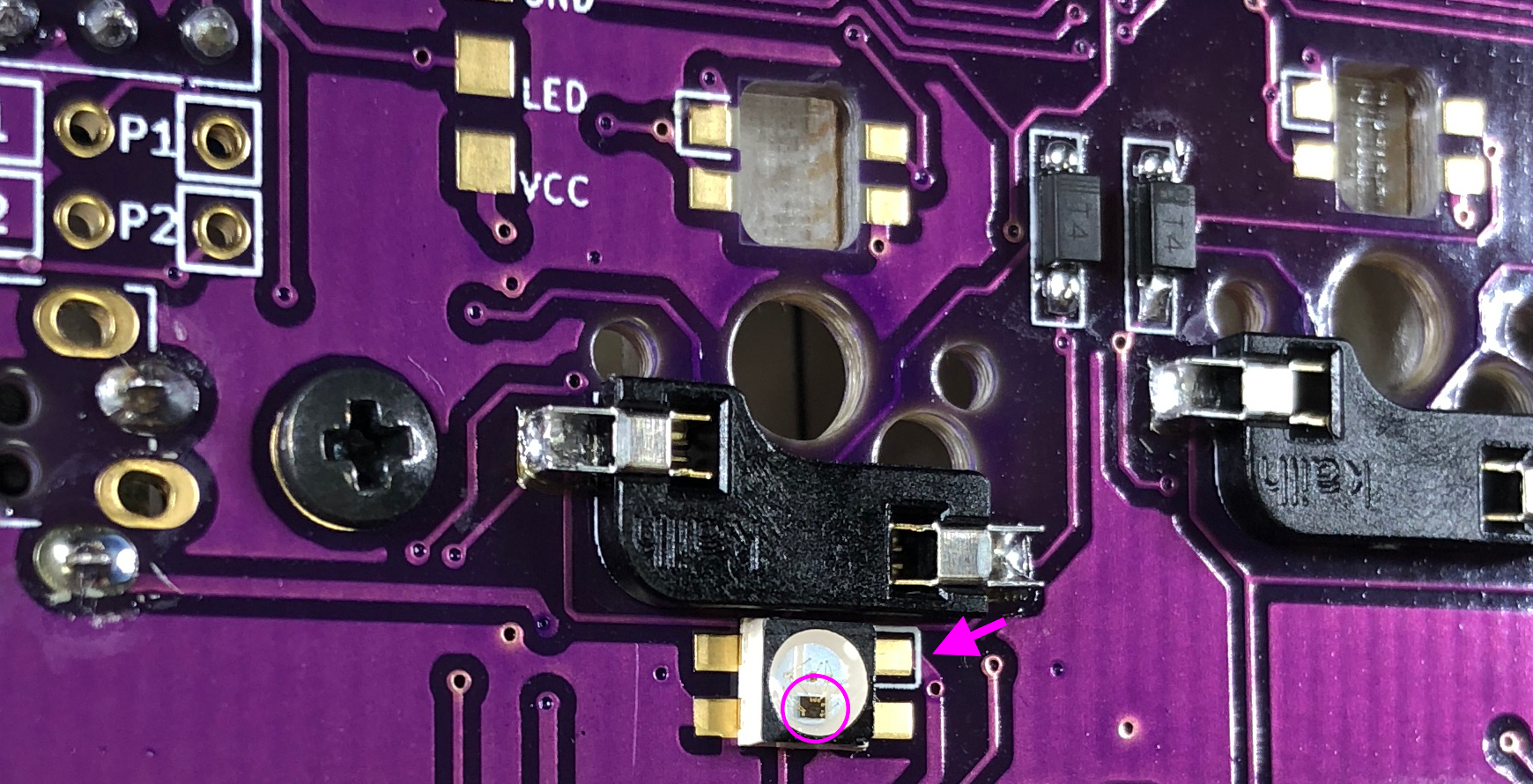

For LEDs 1 to 6,

|

2021-04-17 15:09:15 +02:00

|

|

|

solder the part so that the black part circled below is on the bottom

|

|

|

|

|

and the silk mark indicated by the arrow is on the top.

|

2020-07-07 09:57:59 +02:00

|

|

|

Note that the direction changes between 1 - 3 and 4 - 5.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

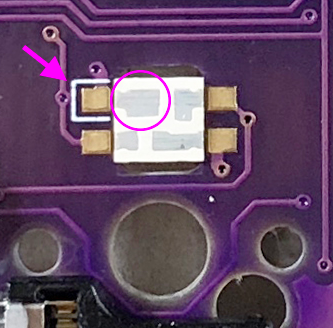

For 7 - 27,

|

2021-04-17 15:09:15 +02:00

|

|

|

perform soldering so that the largest pad surrounded by a circle

|

|

|

|

|

and the silk mark indicated by an arrow are adjacent to each other,

|

2020-07-07 09:57:59 +02:00

|

|

|

as shown below.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

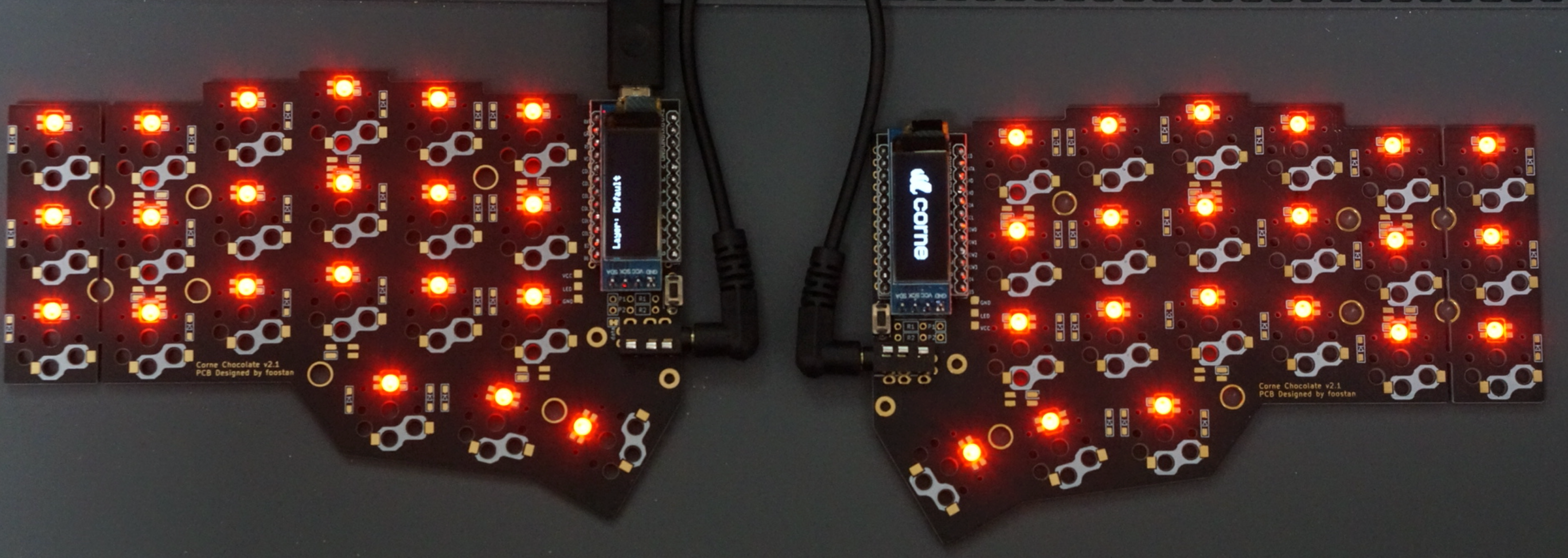

If everything was successfully soldered,

|

|

|

|

|

it will glow as follows.

|

|

|

|

|

If the LED lights only halfway,

|

|

|

|

|

the LEDs are connected in the order of the numbers.

|

|

|

|

|

Therefore, it is likely that the LED that does not emit light

|

|

|

|

|

or the previous LED are incorrectly soldered or damaged.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

### Kailh PCB Socket

|

|

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

|

|

|

|

|

|

|

|

|

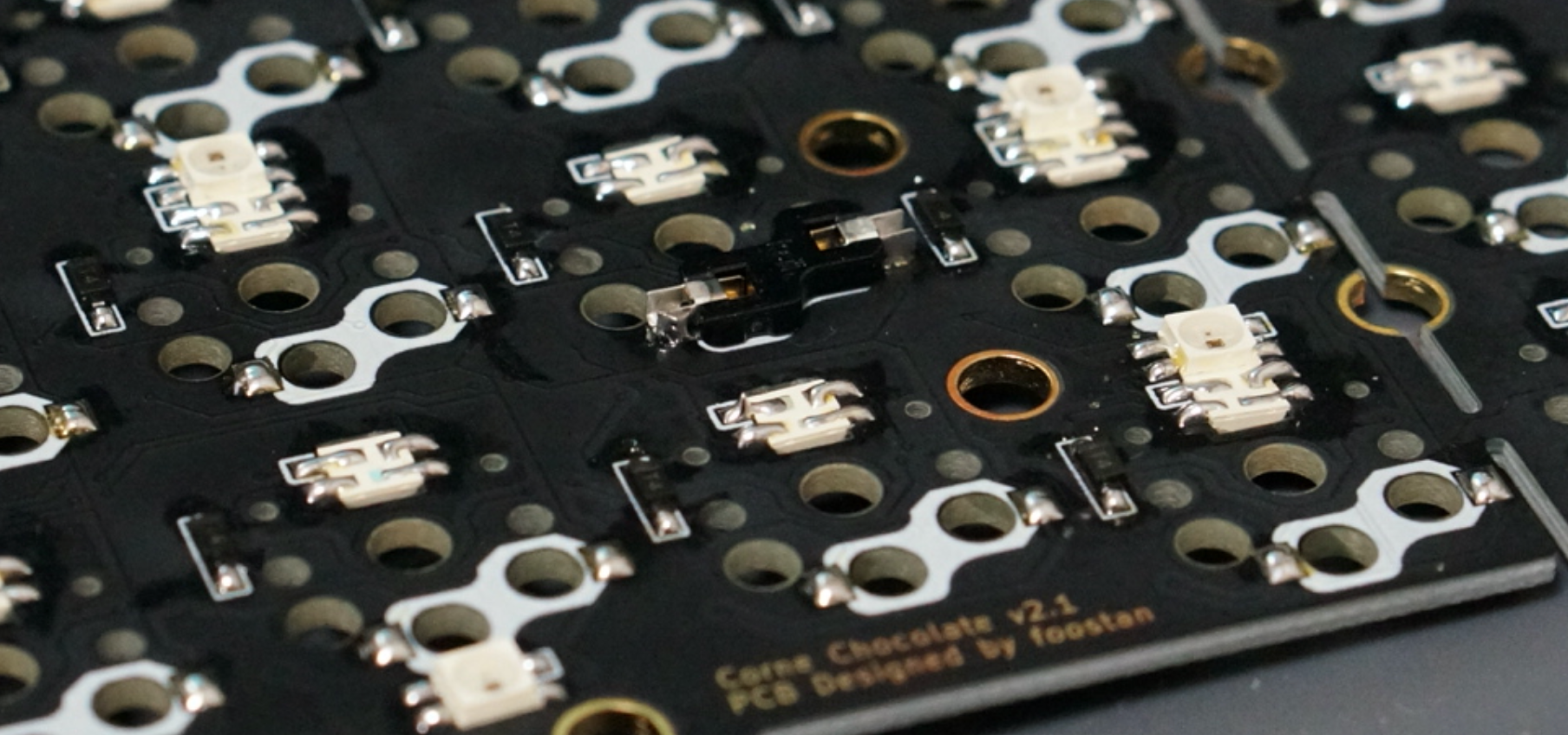

Apply solder to the pads on both sides on the back.

|

|

|

|

|

It is difficult to add it later,

|

|

|

|

|

so please fill it up beforehand.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

Insert the socket and melt the solder.

|

2020-07-07 09:57:59 +02:00

|

|

|

At this time,

|

|

|

|

|

hold the socket with tweezers or your fingers so that the socket sticks to the board.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

The soldering is now complete.

|

|

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

|

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

### Plate, switch

|

|

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-12-01 00:41:17 +01:00

|

|

|

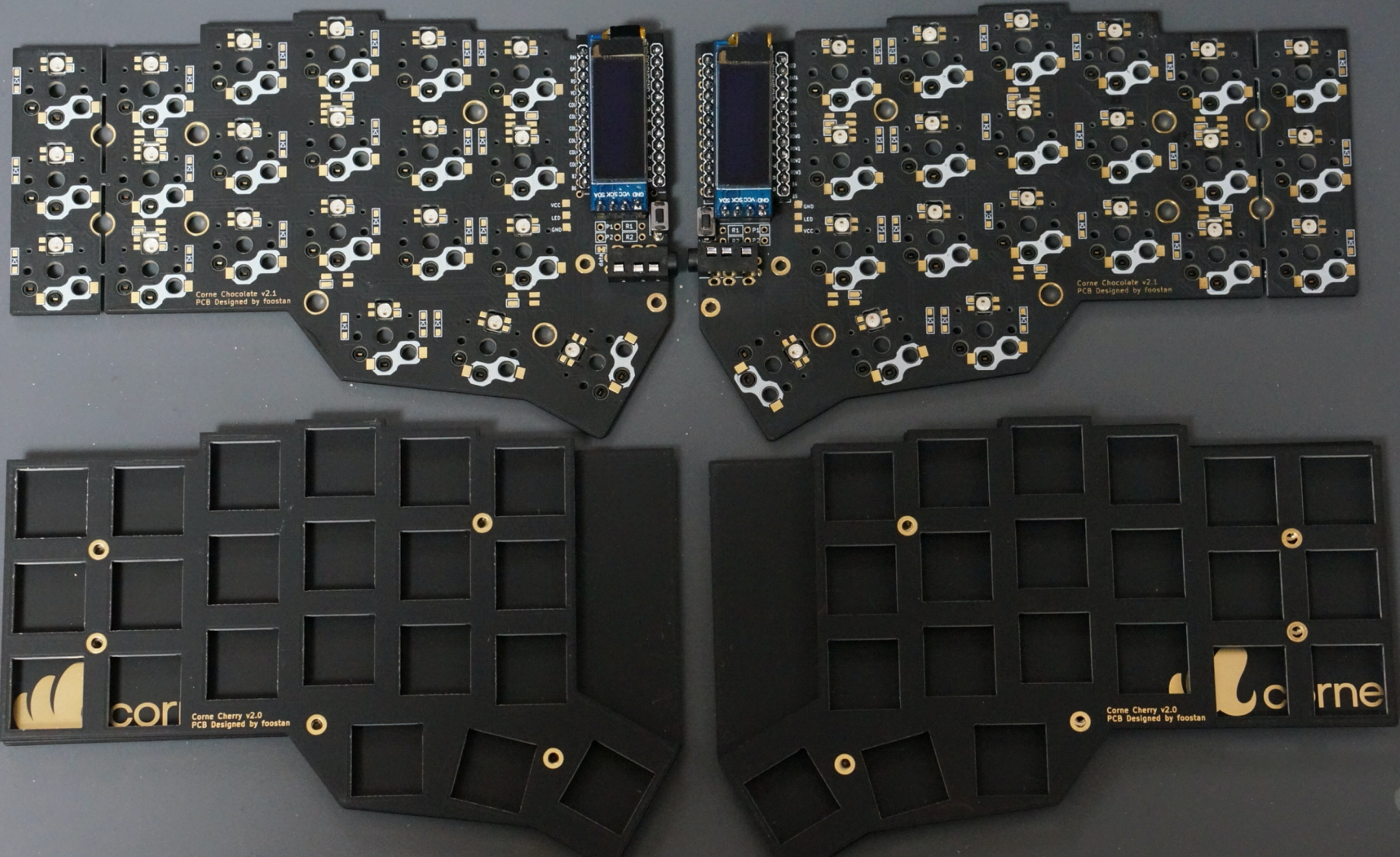

Use 4.5mm spacers for the top and bottom plates

|

|

|

|

|

and 9mm spacers for the OLED.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

In addition,

|

|

|

|

|

it is recommended to paint the side of the plate with a black marker

|

|

|

|

|

because it looks better.

|

2019-12-27 18:44:33 +01:00

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

## Firmware

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2020-11-03 07:18:38 +01:00

|

|

|

See below to flash the firmware to the ProMicro. \

|

2021-04-17 13:34:24 +02:00

|

|

|

<https://github.com/foostan/crkbd/blob/master/doc/firmware_en.md>

|

2019-12-27 18:44:33 +01:00

|

|

|

|

|

|

|

|

This is the end.

|

|

|

|

|

|

2020-07-07 09:57:59 +02:00

|

|

|

|