2018-12-11 08:09:42 +01:00

|

|

|

# Build Guide

|

|

|

|

|

|

|

|

|

|

## Parts

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2018-12-11 08:09:42 +01:00

|

|

|

### Required

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-05-15 08:51:41 +02:00

|

|

|

| Name | Count | Remarks |

|

2018-12-11 08:09:42 +01:00

|

|

|

|:-|:-|:-|

|

|

|

|

|

| PCB | 2 | |

|

|

|

|

|

| Plate | 2 sets | |

|

|

|

|

|

| ProMicro | 2 | |

|

|

|

|

|

| TRRS Jack | 2 | |

|

|

|

|

|

| TRS(3 pole) cable | 1 | TRRS(4 pole) cable works too. |

|

|

|

|

|

| Tact switch | 2 | |

|

|

|

|

|

| Diode | 42 | You need SMD for low profile. |

|

|

|

|

|

| Key Switch | 42 | |

|

|

|

|

|

| Key Cap | 42 | 1u x 40, 1.5u x 2 |

|

2021-04-17 13:34:24 +02:00

|

|

|

| Spacer M2 7.5mm | 10 | use 3mm for low profile |

|

2020-12-01 00:41:17 +01:00

|

|

|

| Spacer M2 9mm or 11mm | 4 | |

|

|

|

|

|

| Screw M2 4mm | 28 | |

|

2018-12-11 08:09:42 +01:00

|

|

|

| Rubber foot | 10 | |

|

|

|

|

|

|

|

|

|

|

### Optional

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-05-15 08:51:41 +02:00

|

|

|

| Name | Count | Remarks |

|

2018-12-11 08:09:42 +01:00

|

|

|

|:-|:-|:-|

|

|

|

|

|

| OLED Module | 1 or 2 | |

|

|

|

|

|

| 4x1 Pin Male Header | 2 | For OLED |

|

|

|

|

|

| 4x1 Pin Female Socket | 2 | For OLED |

|

|

|

|

|

| SK6812MINI | 54 | Front side x 42, back side x 12 |

|

|

|

|

|

| Addressable LED Strip | 2 | exclusive with SK6812MINI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2021-05-15 08:52:32 +02:00

|

|

|

## Advance preparation

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

If you build the firmware yourself,

|

|

|

|

|

it will take some time to set up the environment,

|

|

|

|

|

so it's best to start at the beginning. \

|

|

|

|

|

For more information,

|

|

|

|

|

please see <https://github.com/foostan/crkbd/blob/master/doc/firmware_en.md>.

|

2020-11-03 07:18:38 +01:00

|

|

|

|

2018-12-11 08:09:42 +01:00

|

|

|

## Soldering

|

|

|

|

|

|

|

|

|

|

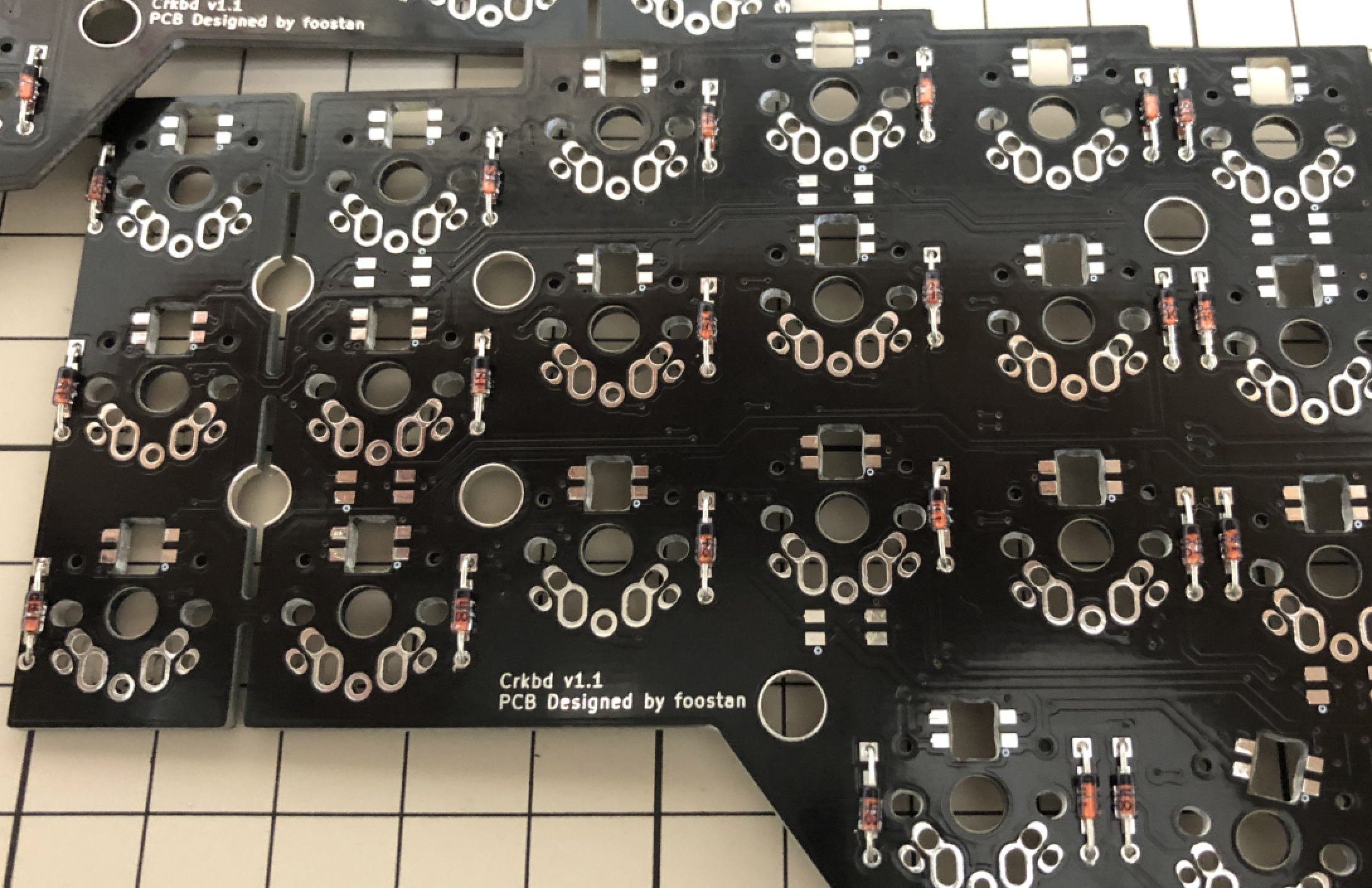

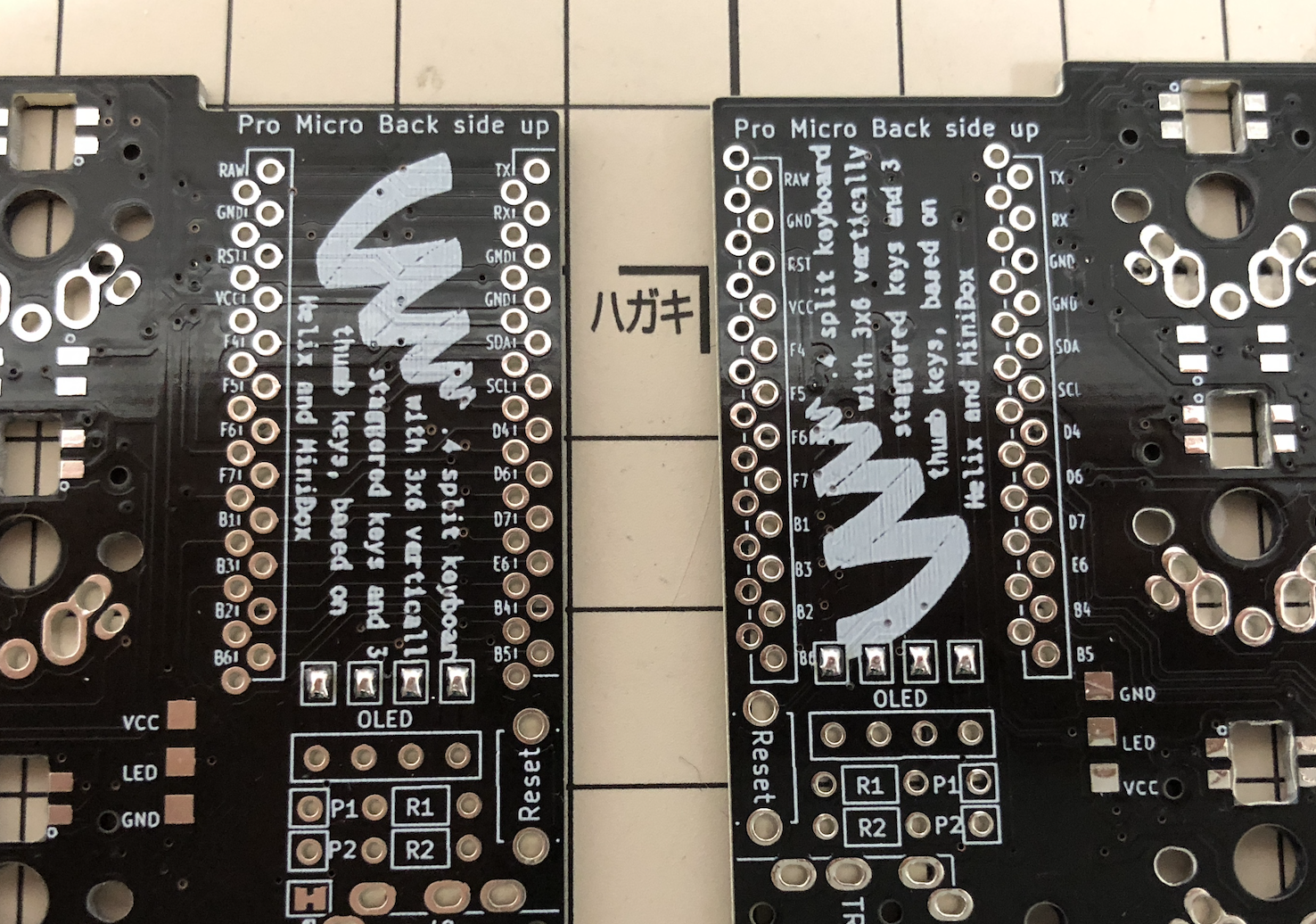

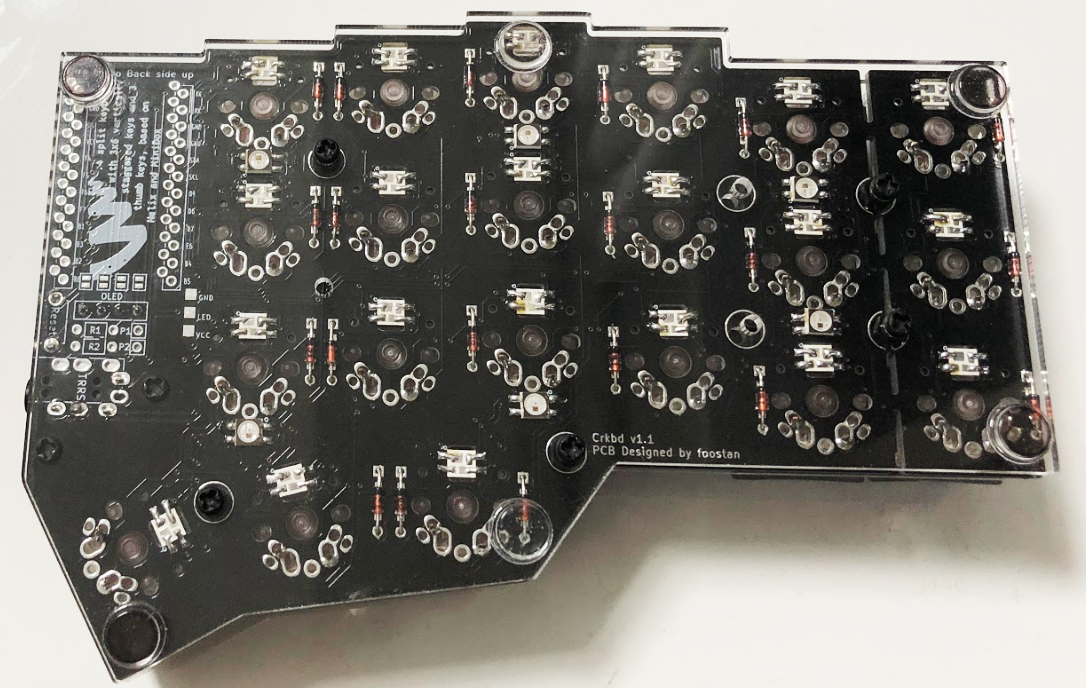

PCB is reversible; use one for the left hand side and the other for the right.

|

|

|

|

|

|

|

|

|

|

### Diodes

|

|

|

|

|

|

2021-04-17 15:07:04 +02:00

|

|

|

#### For non Low Profile keyswitches

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

Solder diodes as indicated in the picture.

|

|

|

|

|

You can place it on either side,

|

|

|

|

|

but front side is recommended if you implement under-glow LED.

|

|

|

|

|

You can use SMD diodes too.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

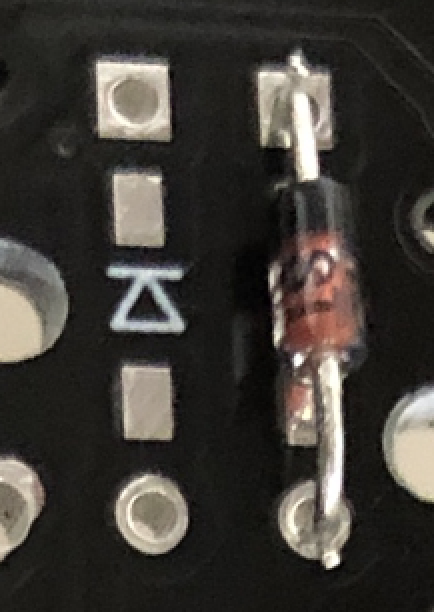

Diode has polarity;

|

|

|

|

|

make sure to match the polarity with PCB silkscreen.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

<- Before | After ->

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2021-04-17 15:07:04 +02:00

|

|

|

#### For Low Profile Keyswitches

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

If you use low profile keyswitches,

|

|

|

|

|

you have to implement SMD diodes __on the back side__.

|

2018-12-11 08:09:42 +01:00

|

|

|

Otherwise, diodes will interfere with top plate.

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

As with normal diodes,

|

|

|

|

|

[SMD diodes have polarity](https://learn.sparkfun.com/tutorials/polarity/diode-and-led-polarity).

|

|

|

|

|

The lines on the SMD diode should be on the same side as the line on the PCB silkscreen.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

### LEDs (Optional)

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

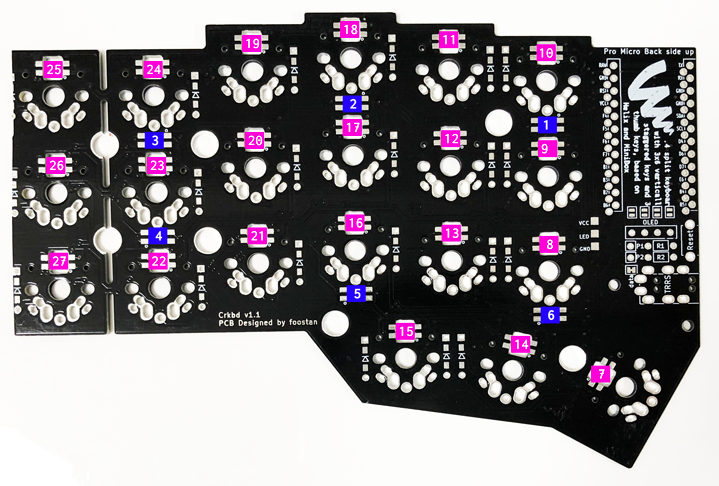

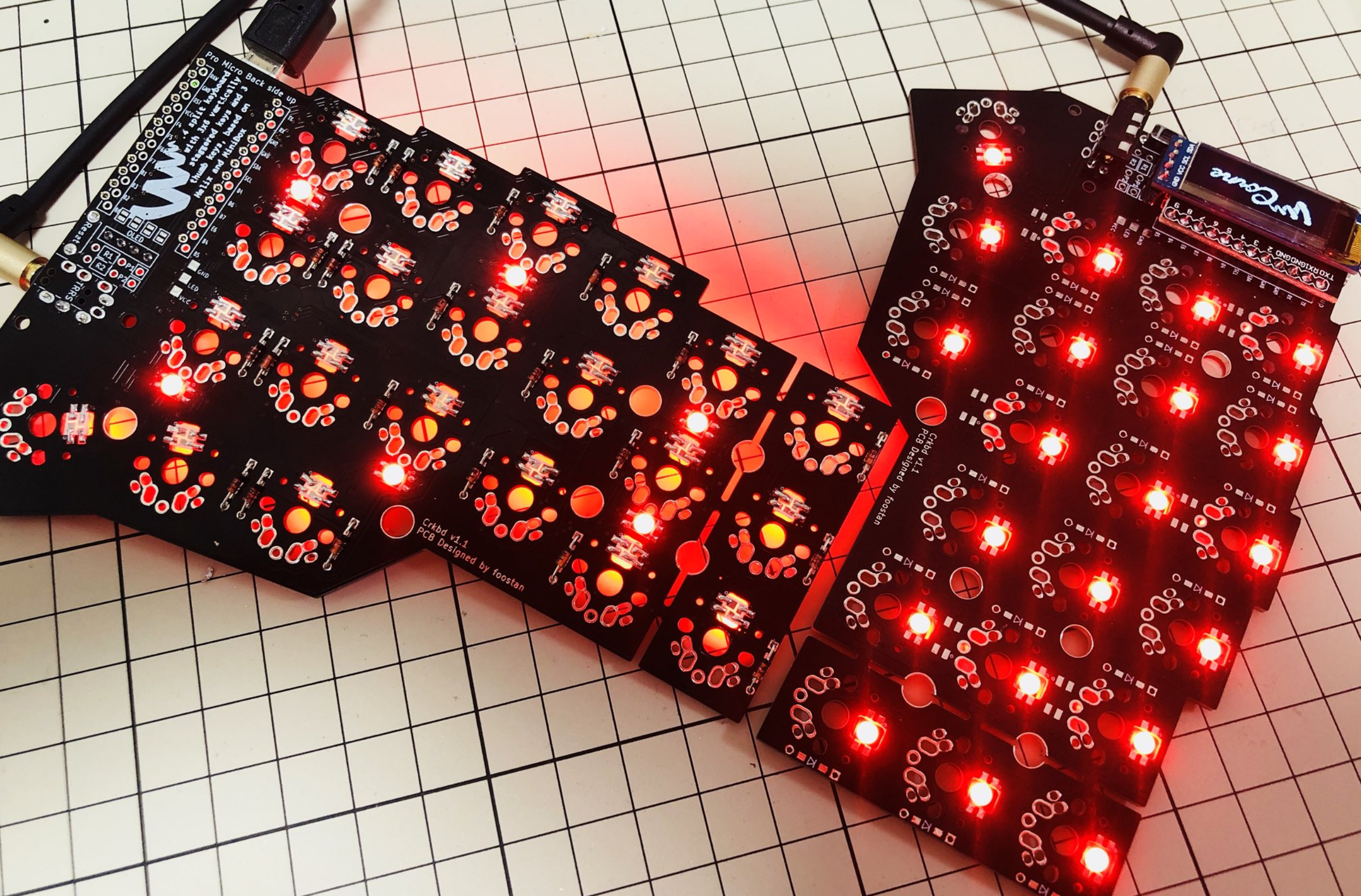

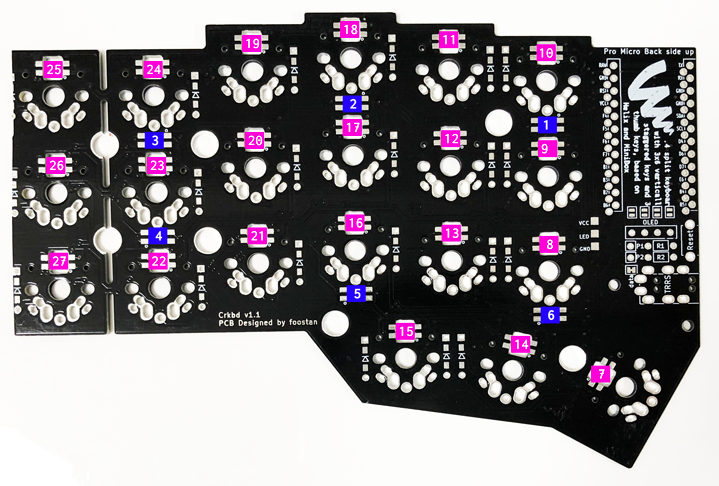

Implement LEDs under keyswitches (No. 7 through 27) upward facing,

|

|

|

|

|

and others (No. 1 through 6) on the back side(under-glow),

|

|

|

|

|

as indicated in the picture.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

For No.7 to 27 LEDs, __Install LEDs from the back side__ as shown below.

|

2021-04-17 15:09:15 +02:00

|

|

|

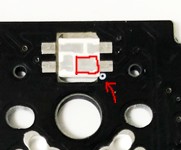

Note the '**o**' silkscreen marking

|

|

|

|

|

and use them as a guide to implement LEDs in the direction.

|

|

|

|

|

On some versions of the PCB (e.g. Corne-cherry v2),

|

|

|

|

|

the '**o**' silkscreen marking has been replaced by a white square

|

|

|

|

|

around one of the pads,

|

|

|

|

|

but the principle is still the same.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

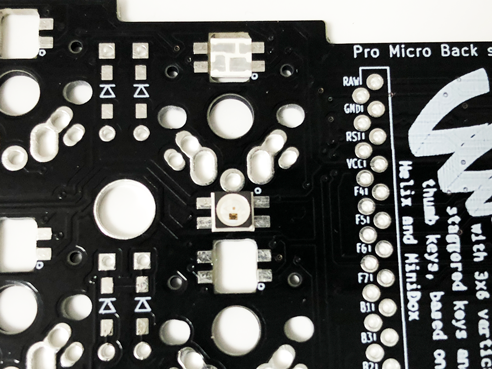

The LED has one pad that is shaped like a square.

|

|

|

|

|

That square should connect to the pad that has the '**o**' silkscreen marking:

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2019-10-10 16:30:04 +02:00

|

|

|

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

There are many different techniques on how to solder the LEDs,

|

|

|

|

|

but [this video](https://twitter.com/foostan/status/1005656803818889216)

|

|

|

|

|

might give you an idea on how to do it.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

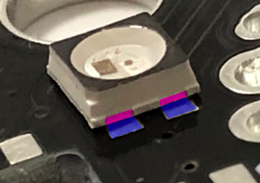

For No. 1 to 6 LEDs, solder the pattern on the side of the device

|

|

|

|

|

(highlighted in pink on the picture) and the PCB pattern (blue on the picture).

|

|

|

|

|

Apply flux and take small amount of solder with a soldering iron

|

|

|

|

|

and press it on the edge of the patterns.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

LEDs are connected in the order of the number on the picture above.

|

|

|

|

|

If it turns on only halfway,

|

|

|

|

|

it is likely that first LED that doesn't turn on

|

|

|

|

|

or the last LED that turns on is not implemented correctly.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

__Note__ that the default Crkbd firmware has __LEDs turned off__,

|

|

|

|

|

so you'll have to turn them on before you can test

|

|

|

|

|

(see the firmware section for instructions how).

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

### Jumpers for OLED modules (optional)

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2018-12-11 08:09:42 +01:00

|

|

|

To use OLED modules, short circuit the jumper patterns.

|

|

|

|

|

__Only short circuit the front side__

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2021-04-17 13:34:24 +02:00

|

|

|

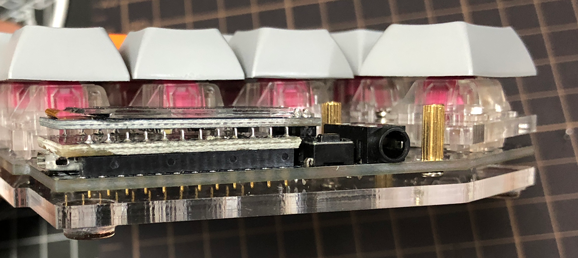

### TRRS socket, reset switch, OLED header sockets

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

Install TRRS sockets and reset switches as in the picture.

|

|

|

|

|

For OLEDs, also implement pin sockets.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

### ProMicro

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

Before you start,

|

|

|

|

|

flash the Crkbd firmware to the ProMicros to make sure they are alright.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

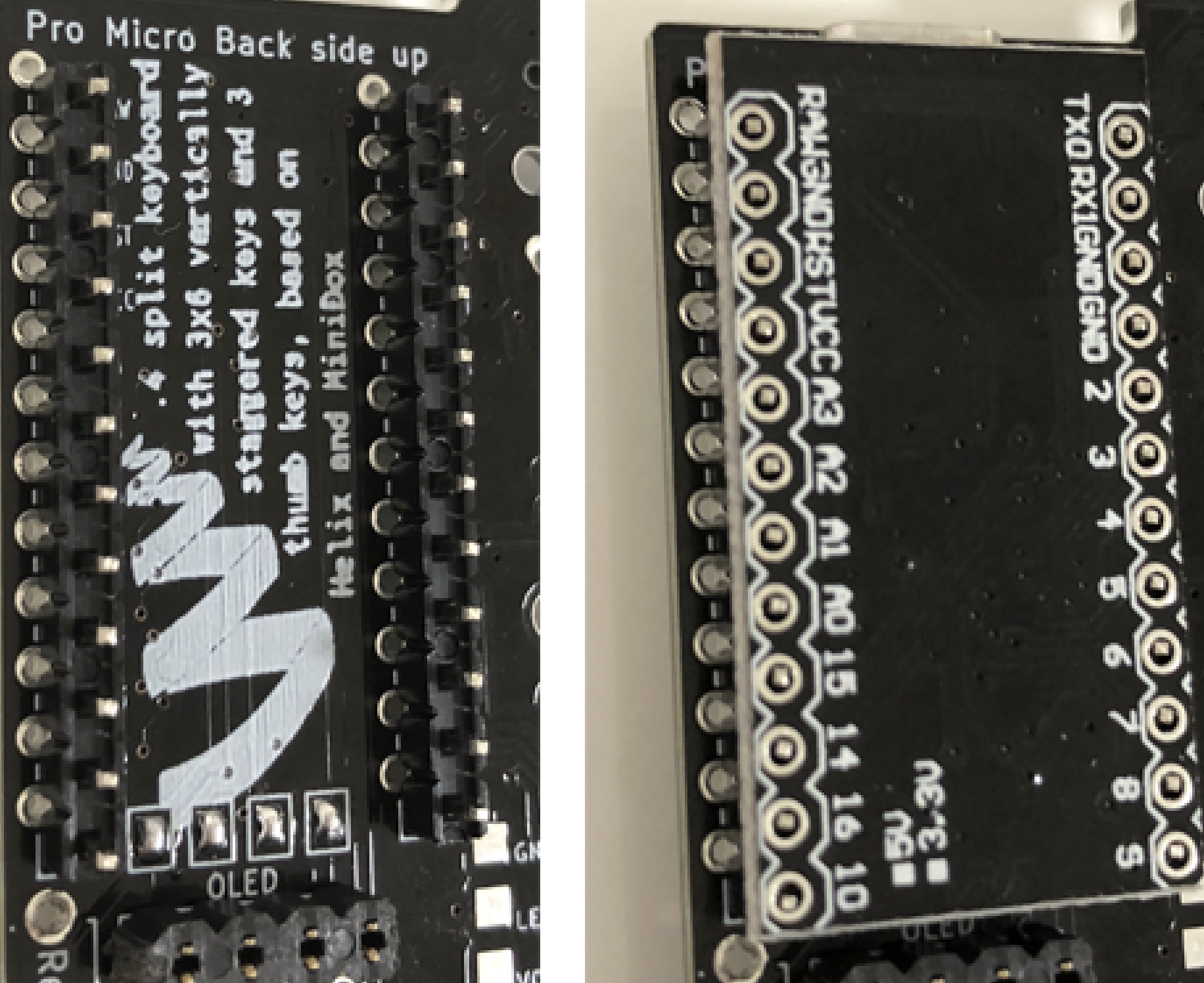

The ProMicro is then installed

|

|

|

|

|

__in the set of holes that has a white frame on the frontside of the PCB__.

|

|

|

|

|

Make sure you solder it in the right set of holes,

|

|

|

|

|

as desoldering the ProMicro is hard.

|

|

|

|

|

Implement pin headers in the white frame,

|

|

|

|

|

then install ProMicro with its __backside up__.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

The picture is the right hand side, but it's the same for the left hand side -

|

|

|

|

|

pins into the through holes in the white frame as seen from the frontside,

|

|

|

|

|

placing the ProMicro with its backside up.

|

2019-10-10 16:32:39 +02:00

|

|

|

|

2018-12-11 08:09:42 +01:00

|

|

|

### OLED Module

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

Implement pin header onto the OLED modules,

|

|

|

|

|

then insert them into the pin sockets.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Adjust the height of the spacer accordingly to the height of pin header.

|

2020-12-01 00:41:17 +01:00

|

|

|

Most common pin header/socket and 11mm spacers are used in the picture.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

### Use socket to Mount ProMicro

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

With using sockets for mounting ProMicro,

|

|

|

|

|

you can replace it easily when it breaks.

|

|

|

|

|

Two methods are introduced here.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

#### Using Spring Loaded Header

|

|

|

|

|

|

2021-05-15 11:20:11 +02:00

|

|

|

Refer to the [Helix build guide](

|

|

|

|

|

https://github.com/MakotoKurauchi/helix/blob/master/Doc/buildguide_en.md#pro-micro)

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

ProMicro kit with spring loaded headers is available at Yusha-Kobo

|

|

|

|

|

|

2021-04-17 13:34:24 +02:00

|

|

|

<https://yushakobo.jp/shop/promicro-spring-pinheader/>

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

Using OLEDs available at Yusha-Kobo which come with low profile header,

|

2022-01-30 12:21:45 +01:00

|

|

|

together with and 9mm spacers, you can build them thin and gap-less.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

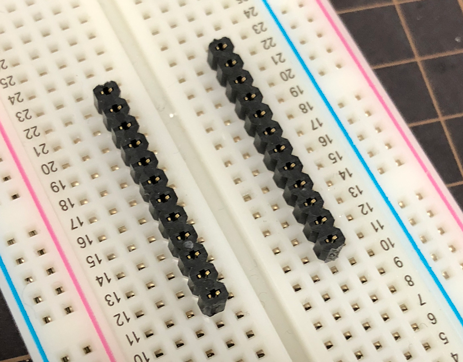

#### Using Pin Sockets

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2018-12-11 08:09:42 +01:00

|

|

|

Low profile pin sockets are available from Akizuki Denshi etc. Requires some work.

|

|

|

|

|

|

2021-04-17 13:34:24 +02:00

|

|

|

<http://akizukidenshi.com/catalog/g/gC-03138/>

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

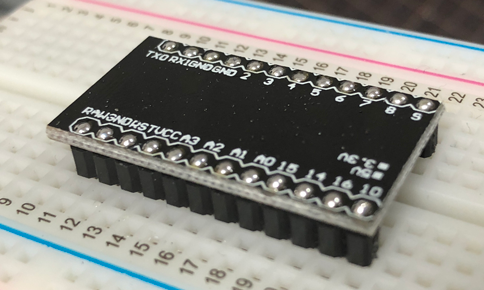

Install a couple of 12x1 pin sockets on a breadboard.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

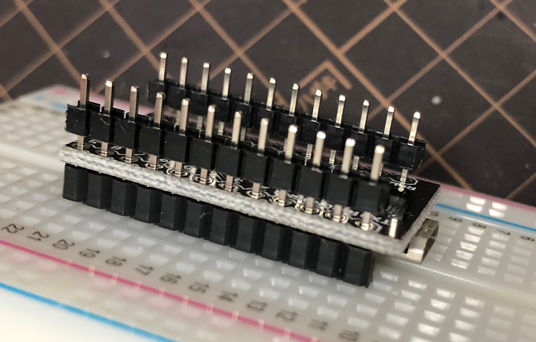

Using male 12x1 pin headers, fixate ProMicro onto the pin sockets.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

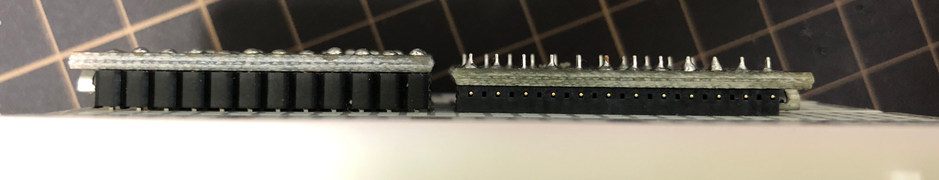

Remove plastic pin holders, solder the pins to ProMicro,

|

|

|

|

|

and then cut extra pins.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

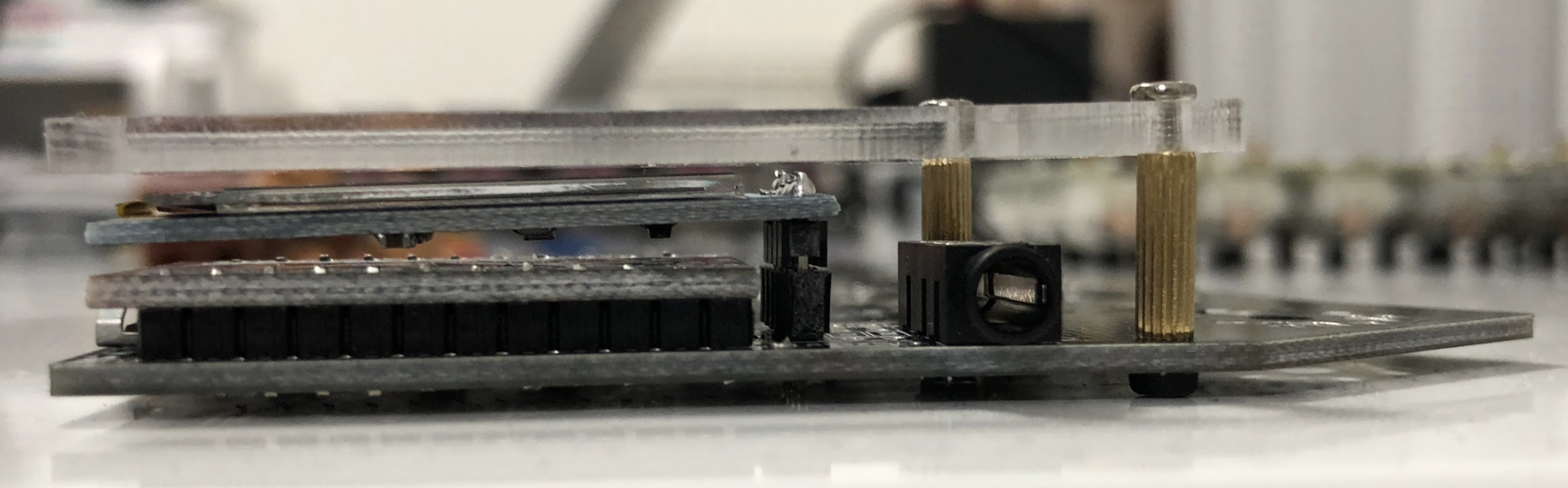

#### Comparison

|

|

|

|

|

|

|

|

|

|

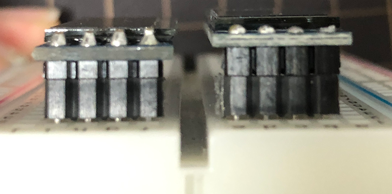

Spring loaded headers can make the height lower.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

Comparing pin-headers in the picture.

|

|

|

|

|

Headers come with OLED available at Yusha-Kobo are lower.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

### Testing

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

It is recommended to test the ProMicro and OLED modules

|

|

|

|

|

before installing keyswitches,

|

|

|

|

|

because rework would be difficult after that.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

First, build QMK Firmware for built for Crkbd

|

|

|

|

|

and install on ProMicro (if you haven't already done so).

|

2019-10-10 16:34:59 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

|

2019-10-10 16:34:59 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

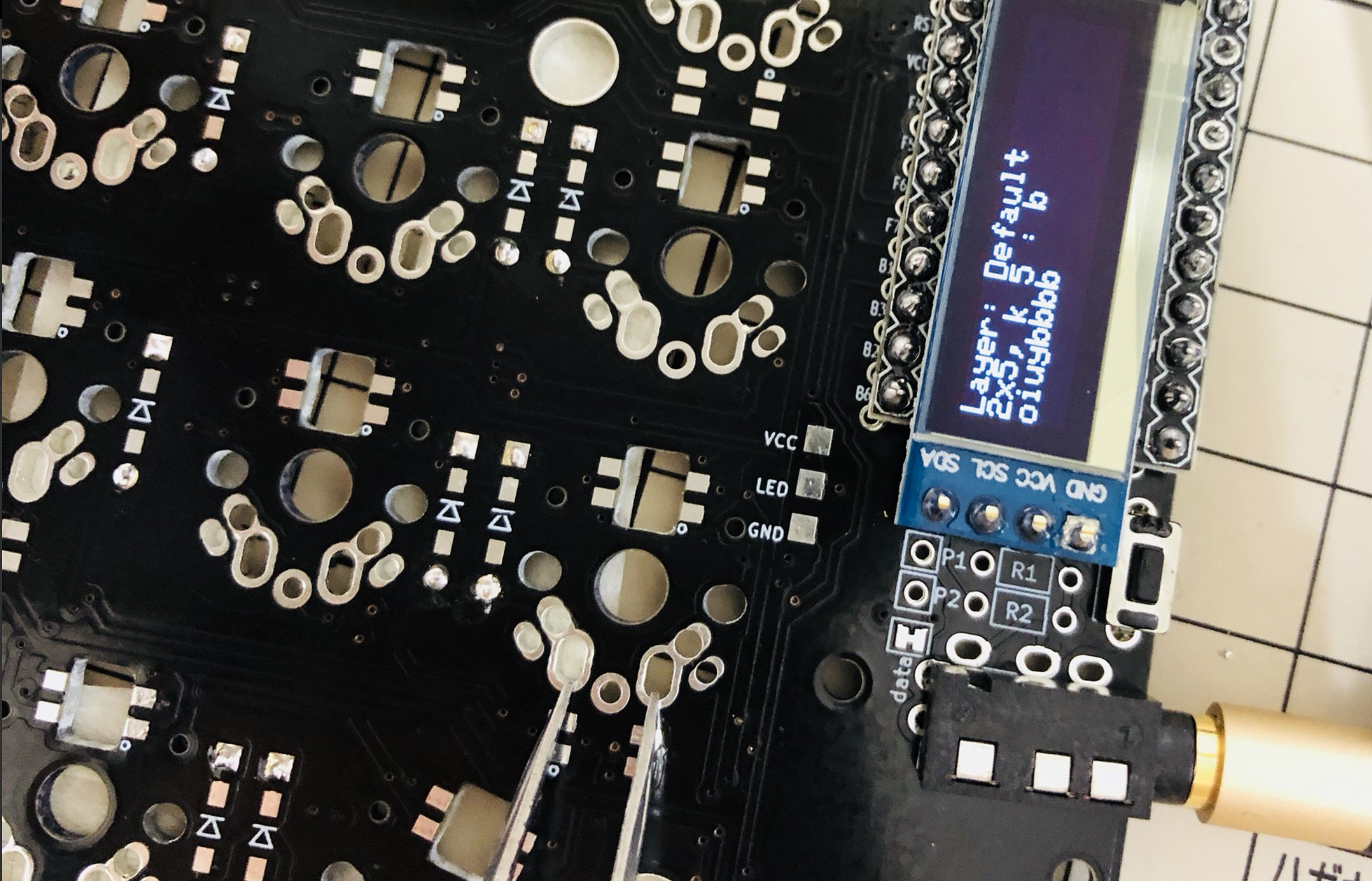

Using the default keymap,

|

|

|

|

|

OLED will show information on the keyswitches being pressed.

|

|

|

|

|

Check the connections by short-circuiting keyswitch soldering pads

|

|

|

|

|

with tweezers or a bit of soldering wire.

|

|

|

|

|

Check all of them.

|

|

|

|

|

|

|

|

|

|

If you have OLED displays,

|

|

|

|

|

you can verify that all keys are responding

|

|

|

|

|

by looking at the log information showed there.

|

|

|

|

|

It will say which row and column was pressed,

|

|

|

|

|

e.g. `1x5` or `0x2`. Using the tweezers or wire,

|

|

|

|

|

connect each buttons soldering pads and make sure the display changes.

|

|

|

|

|

If something isn't working,

|

|

|

|

|

take note of the which row x column it is that isn't working,

|

|

|

|

|

as it can help when troubleshooting.

|

|

|

|

|

|

|

|

|

|

If you have mounted LEDs,

|

|

|

|

|

also make sure all of them are turned on.

|

|

|

|

|

As note before, the default firmware has LEDs __turned off__,

|

|

|

|

|

so you have to turn them on in the firmware before you test.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

### Keyswitches and Top Plate

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2018-12-11 08:09:42 +01:00

|

|

|

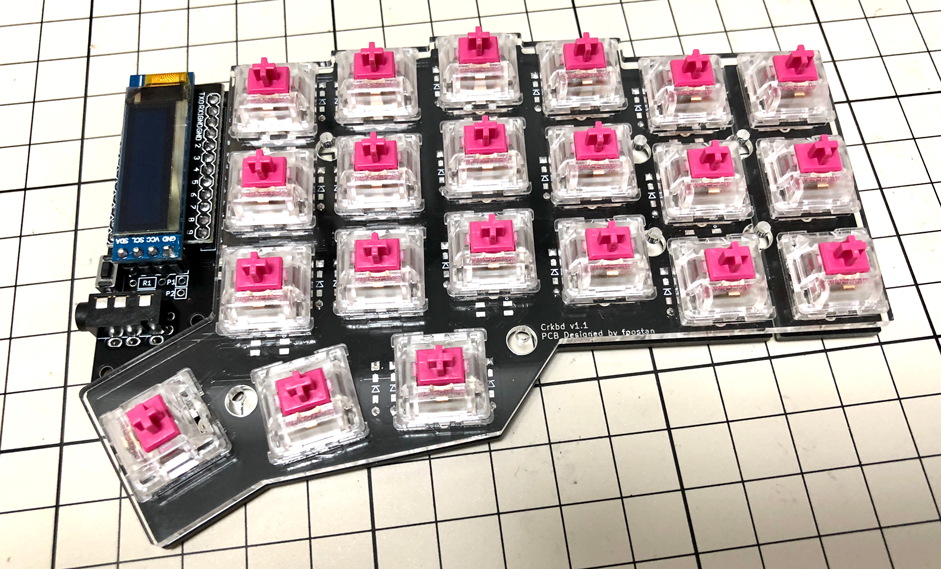

Sandwich top-plate with PCB and key-switches.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

### Bottom Plate

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2018-12-11 08:09:42 +01:00

|

|

|

Use 3mm spacers for low-profile,

|

2020-12-01 00:41:17 +01:00

|

|

|

Attach bottom plate to the PCB using 7.5mm (3mm for low-profile) spacers.

|

2018-12-11 08:09:42 +01:00

|

|

|

Then attach six rubber feet.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

### Keycaps

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2018-12-11 08:09:42 +01:00

|

|

|

Lastly install keycaps.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

## Firmware

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2020-11-03 07:18:38 +01:00

|

|

|

See below to flash the firmware to the ProMicro. \

|

2021-04-17 13:34:24 +02:00

|

|

|

<https://github.com/foostan/crkbd/blob/master/doc/firmware_en.md>

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2019-10-10 16:38:44 +02:00

|

|

|

### Turning LEDS on

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

To turn the LEDs on, you have to edit the `rules.mk` file.

|

|

|

|

|

If you use the default layout,

|

|

|

|

|

it can be found here `keyboards/crkbd/keymaps/default/rules.mk`.

|

|

|

|

|

Add the following line to the top of the file:

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2019-10-10 16:38:44 +02:00

|

|

|

```

|

2019-12-29 03:59:59 +01:00

|

|

|

RGBLIGHT_ENABLE = yes

|

2019-10-10 16:38:44 +02:00

|

|

|

```

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

Compile and flash to both sides and all LEDs should turn on

|

|

|

|

|

and __glow red__ if you have soldered everything correctly.

|

|

|

|

|

If you run the default firmware and the LEDs turn a differrent color,

|

|

|

|

|

the data to the LEDs is probably corrupted somewhere along the way.

|

|

|

|

|

Check the LED before the first one

|

|

|

|

|

turning a different color using the troubleshooting guide below.

|

2018-12-11 08:09:42 +01:00

|

|

|

|

2020-07-06 08:58:38 +02:00

|

|

|

## Troubleshooting

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2020-07-06 08:58:38 +02:00

|

|

|

Here are some tips and tricks on how to troubleshot a board that is not working.

|

|

|

|

|

|

|

|

|

|

### No LEDs turn on

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

There are a number of things that might be wrong.

|

|

|

|

|

First of all, make sure you have __turned on LED lighting in the firmware__.

|

|

|

|

|

If that is the case, then chances are there might be a problem with the first LED.

|

|

|

|

|

Try the suggestions in the next section.

|

2020-07-06 08:58:38 +02:00

|

|

|

|

|

|

|

|

### Some LEDs not turning on

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

If some LEDs aren't turning on,

|

|

|

|

|

check the first LED not turning on __or__ the one before it.

|

2020-07-06 08:58:38 +02:00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here are some things to try out:

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

- Make sure the LED is soldered correctly.

|

|

|

|

|

Check the pads to see if it looks like they have a proper connection.

|

|

|

|

|

- Check the LED orientation.

|

|

|

|

|

Use the pictures above the see the correct orientation.

|

|

|

|

|

Since the first LED is soldered with its back against the PCB,

|

|

|

|

|

you might have to determinewhat the orientation should look like from the front

|

|

|

|

|

using LEDs 7-27 (just double check that they are oriented correctly first).

|

|

|

|

|

- If both of the above looks good, chances are the LED was damaged during soldering.

|

|

|

|

|

Either replace it directly or use the diod mode of a multimeter to test the connectivity.

|

|

|

|

|

One way to do this is by simply comparing to some of the other LEDs you have soldered.

|

|

|

|

|

Choose two of the LED's pads (out of the four available)

|

|

|

|

|

and compare the reading to that of some of the other LEDs

|

|

|

|

|

(taking care to measure the same pads with the same needles of your multimeter).

|

|

|

|

|

Work your way through all combinations of pads and needles.

|

|

|

|

|

If the differ, you either have a broken LED or bad connectivity.

|

|

|

|

|

Or simply desolder the LED directly, might be quicker. :)

|

2020-07-06 08:58:38 +02:00

|

|

|

|

|

|

|

|

### A full row/column of keys not working

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

If a full row or column of keys is not working,

|

|

|

|

|

then the culprit is most likely the connection between the PCB and the ProMicro.

|

|

|

|

|

Check your soldering and make sure there's a proper connection

|

|

|

|

|

and that you have soldered the ProMicro in the right set of holes.

|

|

|

|

|

If soldering looks okay, then your ProMicro might be damaged.

|

|

|

|

|

You can exclude the possibility of problems with the PCB,

|

|

|

|

|

paths and diodes by short circuiting the pins on the ProMicro directly,

|

|

|

|

|

using a bit of wire.

|

|

|

|

|

Connecting one row pin with one column pin should result in the corresponding key.

|

|

|

|

|

Some PCBs have silkscreen print indicating which pin is which row or column,

|

|

|

|

|

to make this process easier.

|

2020-07-06 08:58:38 +02:00

|

|

|

|

|

|

|

|

### Random key(s) not working

|

2021-04-17 13:34:24 +02:00

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

If it is not a full row or column of keys that are not working,

|

|

|

|

|

the issue is most likely that there's no connection between the key and the ProMicro.

|

|

|

|

|

There are multiple places where the connection can get interupted:

|

2020-07-06 08:58:38 +02:00

|

|

|

|

|

|

|

|

- between keyswitch and PCB (if you have installed the switches)

|

|

|

|

|

- between keyswitch and hotswap socket (if you use them)

|

|

|

|

|

- between hotswap socket and PCB (again, if you use hotswap sockets)

|

|

|

|

|

- in the diodes between the key and the ProMicro

|

|

|

|

|

- in the paths inside the PCB

|

|

|

|

|

|

2021-04-17 15:09:15 +02:00

|

|

|

If you have installed the keyswitches already,

|

|

|

|

|

then check the soldering on the keyswitch.

|

|

|

|

|

if you use hotswap sockets,

|

|

|

|

|

check that you didn't accidentally bend one of the legs of the switch

|

|

|

|

|

when inserting into the socket and that the socket soldering is alright.

|

|

|

|

|

|

|

|

|

|

Next, visually inspect the PCB.

|

|

|

|

|

If it looks scratched or damaged anywhere along the path

|

|

|

|

|

from ProMicro to diode to keyswitch, the path might be interrupted.

|

|

|

|

|

If you find a spot that looks damaged,

|

|

|

|

|

you can use some wire to bypass the section that is damaged

|

|

|

|

|

(e.g. connecting the ProMicro directly to the first pad of the diode).

|

|

|

|

|

If this fixes the key, then you can either opt to keep the wire permanently,

|

|

|

|

|

or you can try to repair the path.

|

|

|

|

|

The path can be repaired by carefully scraping off the paint

|

|

|

|

|

from a section of the path that is okay on either side of the damaged part

|

|

|

|

|

(use a small flat head screwdriver intended for electronics).

|

|

|

|

|

Then clean carefully with alcohol and solder a new connection.

|

|

|

|

|

Youtube might have some guides on how to do this.

|

|

|

|

|

|

|

|

|

|

If the PCB looks okay, then the diode would be the next thing to check.

|

|

|

|

|

Begin by checking the soldering.

|

|

|

|

|

If it looks okay, then the diode itself might be damaged.

|

|

|

|

|

If you have a multimeter, use it to check the diode.

|

|

|

|

|

The reading should be the same as for diodes connected to keys that are working

|

|

|

|

|

(when measuring, remember that diodes have polarity).

|

|

|

|

|

You can also use tweezers or a bit of soldering wire

|

|

|

|

|

to connect the soldering pads on each side of the diode if you don't have a multimeter.

|

|

|

|

|

Pressing the key (or short circuiting the pads where the key would go)

|

|

|

|

|

after connecting the pads should make a key press being registered.

|

|

|

|

|

If this is the case, or if you used the multimeter

|

|

|

|

|

and got a different reading from the diode,

|

|

|

|

|

then check your soldering and replace the diode if necessary.

|